Myron L 6P and 4P User Manual

Page 48

44

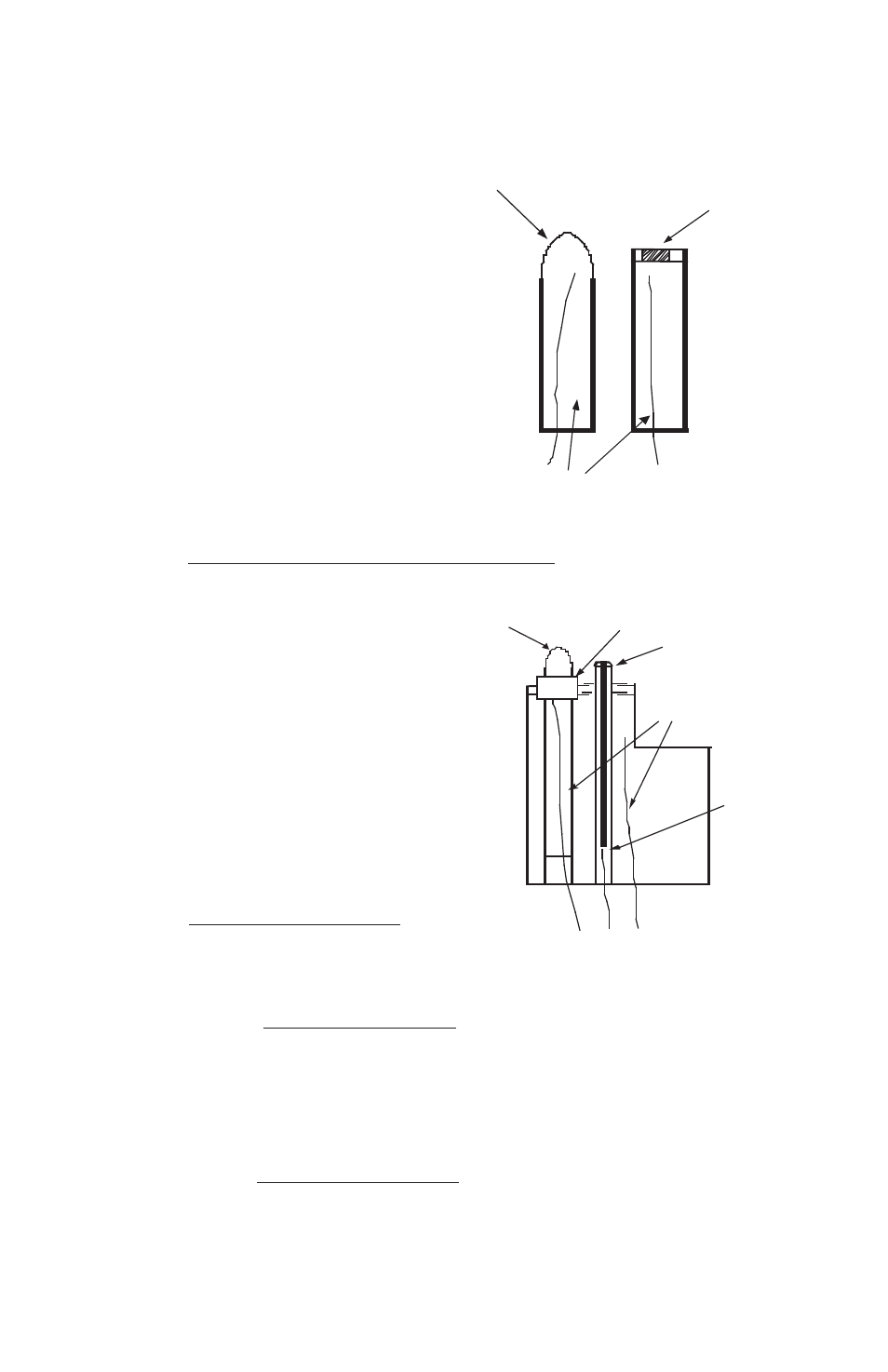

The problem is, on the other side of the membrane is an unknown test

solution, not potassium chloride. The outside electrode, also called

the Reference Junction, is of the same construction with a porous

plug in place of a glass barrier to

allow the junction fluid to contact

the test solution without significant

migration of liquids through the plug

material. Figure 33 shows a typical

2 component pair. Migration does

occur, and this limits the lifetime

of a pH junction, from depletion of

solution inside the reference junction

or from contamination. The junction

may be damaged if dried out

because insoluble crystals may form

in a layer, obstructing contact with

test solutions. See pH/ORP, pg. 43.

4. The Myron L Integral pH Sensor (6P)

The sensor in the Ultrameter II

(see Figure 34) is a single

construction in an easily

replaceable package. The sensor

body holds an oversize solution

supply for long life. The reference

junction “wick” is porous to provide

a very stable, low permeable

interface, and is located under the

glass pH sensing electrode. This

construction combines all the best

features of any pH sensor known.

5. Sources of Error (6P)

The basics are presented in

pH/ORP, pg. 43.

a. Reference Junction

The most common sensor problem will be a clogged junction because a

sensor was allowed to dry out. The symptom is a drift in the “zero” setting

at 7 pH. This is why the Ultrameter II does not allow more than 1 pH unit

of offset during calibration. At that point the junction is unreliable.

b. Sensitivity Problems

Sensitivity is the receptiveness of the glass surface. A film on the surface

can diminish sensitivity and cause a long response time.

Glass surface

Figure 33

KCl solution

Electrode wire

Electrode

wire

H

+

ions

Junction

Plug

KCl solution

Figure 34

Junction plug

Platinum button

H

+

ions

Electrode wires

Glass

Glass

Surface