Components, Supporting documentation – Dow Protected Membrane Roof EN User Manual

Page 9

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

C

O

M

P

O

N

E

N

T

S

–

F

a

b

r

i

c

9

Components

F A B R I C

Installation Notes

Store all materials in dry,

protected areas in an upright

position.

Dow experience has shown

that when STYROFOAM

™

Brand

Extruded Polystyrene Foam

Insulation is exposed to both

direct sunlight and an outdoor

air temperature over 90°F (32°C),

distortion of the foam can occur

in as little as 30 minutes when a

heavy, dark-coloured fabric is over

the insulation. To prevent this

phenomenon during hot weather,

temporarily place white opaque

polyethylene film on the fabric

until the ballast is laid (or use a

white filter fabric).

Install the fabric unadhered

directly over the foam insulation.

Wetting the fabric sometimes

helps secure it until the ballast

can be applied.

Supporting

Documentation

Blueprint 501a: “Protecting

STYROFOAM

™

Brand Insulation

Below Dark Roofing Membranes

and Fabrics”

Extend the fabric up the

roof perimeter cants and roof

protrusions by at least 3" (75 mm)

above the top level of the ballast

(typically about a 6" [150 mm]

upturn) and place it loose under

the metal counterflashings (Figure 5).

Fabrics, such as Fabrene V.I.E.,

†

should meet or exceed the

guidelines listed in Table 1.

For a complete list of accept-

able filter fabrics, contact a Dow

representative.

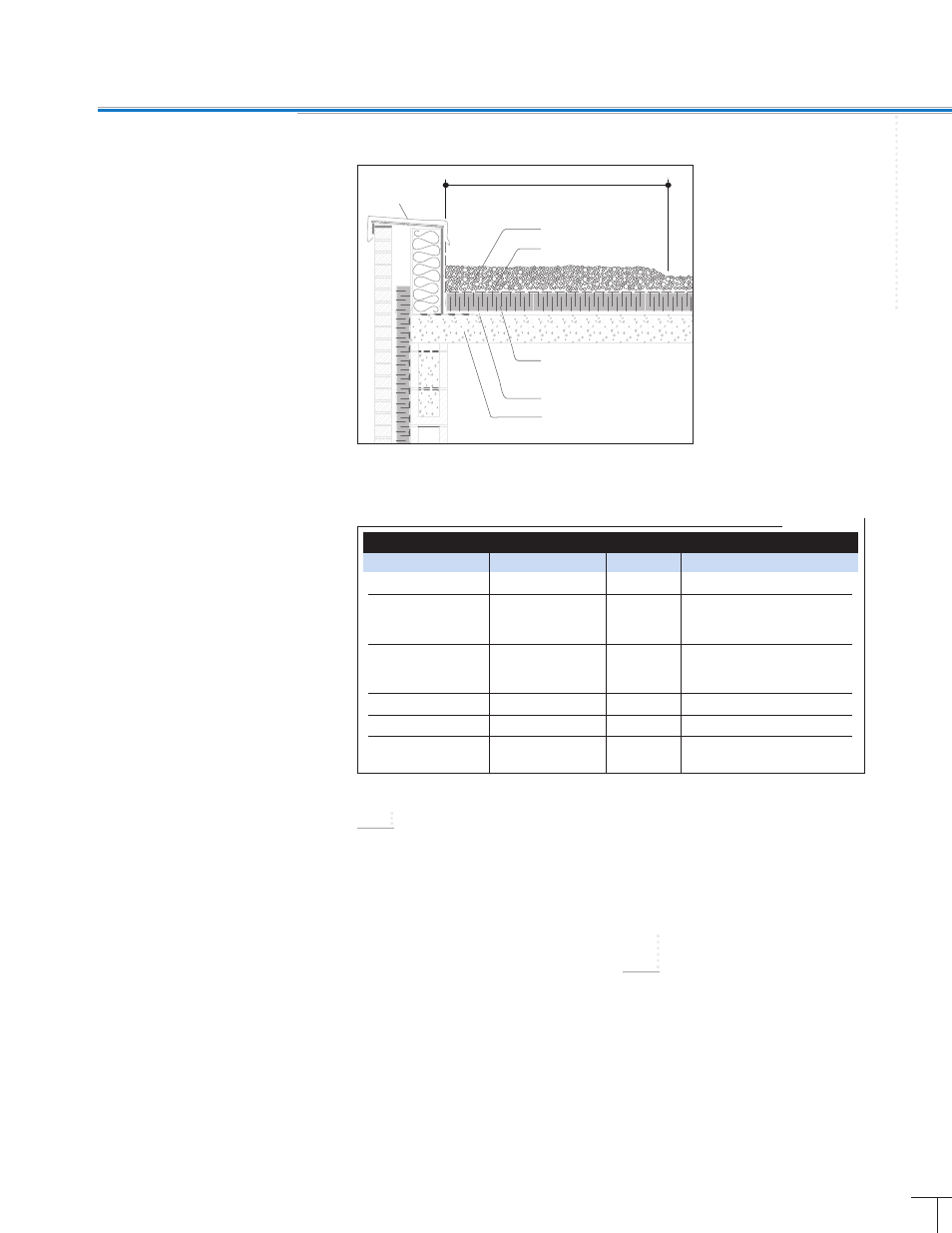

Deck

Membrane

Ballast

Filter Fabric

STYROFOAM

™

Flashing

8' 6"

Ballast at 22 lbs/ft

2

to 4 Feet

in from Parapet for Wind Uplift

Around Entire Perimeter of Roof

Brand Foam Insulation

Figure 5: Parapet Detail With Fabric**

T A B L E

1

**This is an illustration of a typical detail. Responsibility for actual design remains that

of the designer.

†

Fabrene V.I.E. is a registered trademark of PGI - Fabrene Inc.

Specification Guidelines

Criteria

Test Method

Units

Value

Unit Weight

ASTM D1910

oz/yd

2

4.0 (max)

Notch Tear

lb

MD

ASTM D2262

7.0 (min)

CD

7.0 (min)

Tensile Grab

lbf

MD

ASTM D1682

70 (min)

CD

60 (min)

Elongation @ break

ASTM D1682

%

15 (min)

UV Resistance

Approved for outdoor use

Material

Woven polyolefin preferred

to promote run-off