Components, Description, Function – Dow Protected Membrane Roof EN User Manual

Page 8: Specification

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

**This is an illustration of a typical detail. Responsibility for actual design remains that of the designer.

C

O

M

P

O

N

E

N

T

S

–

F

a

b

r

i

c

8

Components

F A B R I C

Description

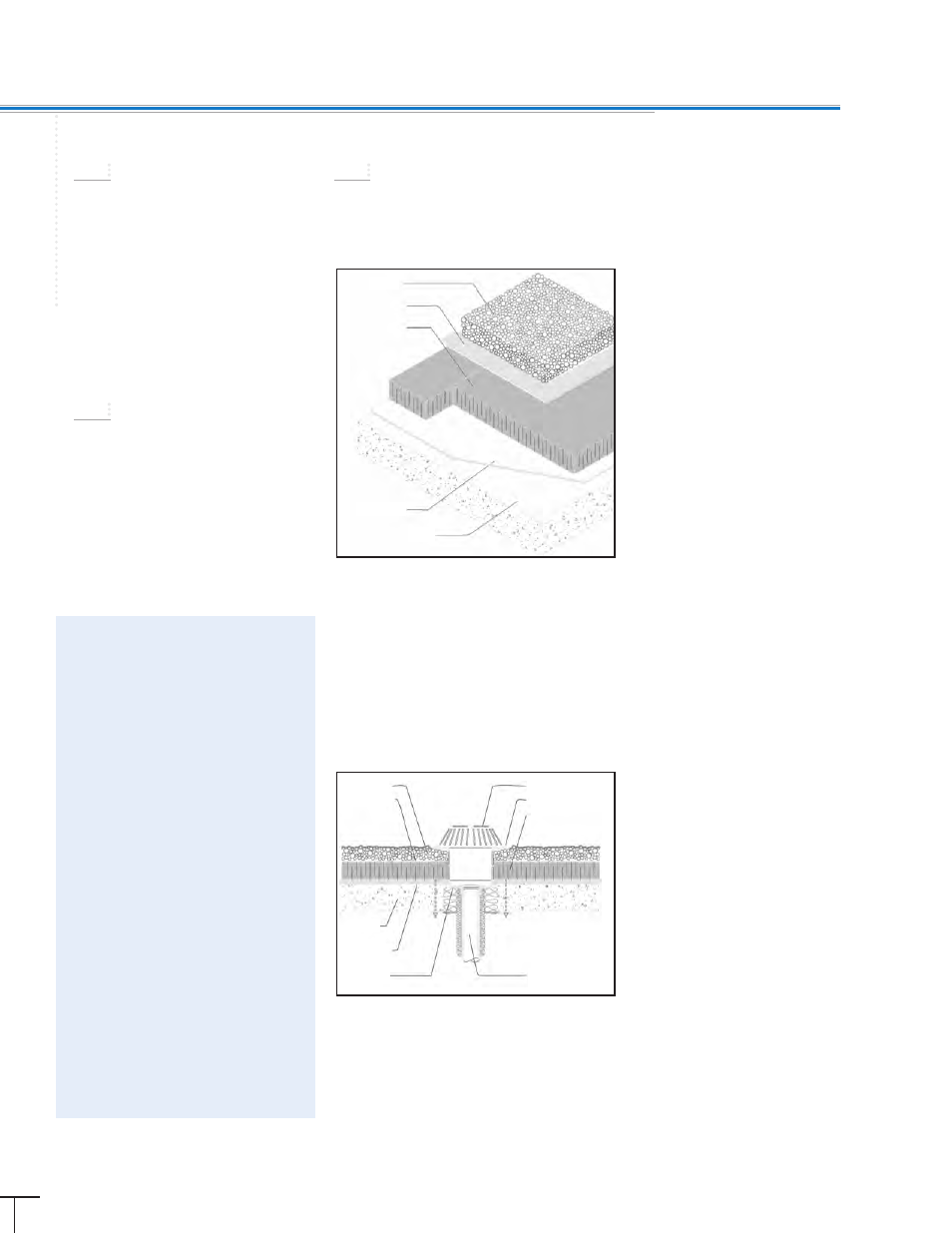

Ballast reduction fabric,

commonly known as filter

fabric, is used in PMR installa-

tions between the ballast and

insulation. This water-permeable

material must have proven long-

term weather resistance, be strong

enough to withstand traffic

abuse and prevent displacement

of the insulation under flotation

conditions.

Function

• Prevent fines from penetrating

between insulation boards

• Raft the insulation together

to reduce ballast requirements

• Reduce mechanical damage

to insulation

• Allow easy stone removal if

access is required to flashings,

insulation and/or membrane

Overlap all edges a minimum

of 12" (300 mm). If a small piece

has to be used, minimum size

should be 8' x 8' (2.5 m x 2.5 m).

Slit fabric to fit over any roof

penetrations. Cut around roof

drains and other openings

(Figure 4).

Specification

Apply fabric unbonded and

shingle fashion over the installed

insulation (Figure 3).

Ballast

Filter Fabric

STYROFOAM™

Brand Foam

Insulation

Membrane

Deck

STYROFOAM™

Brand Foam

Insulation

Ballast

Filter Fabric

Membrane

Deck

Drain Body

Drain Line With

Insulation Wrap

Drain Cap

Exterior Drain Body

Figure 3: Fabric Placement**

Figure 4: Drain Detail With Fabric**

IMPORTANT: When scheduling

or weather conditions delay

installation of plaza, patio

deck or garden roof PMR

areas, care must be taken to

ensure that dark-coloured

products, such as black plastic

drainage boards (dimple

boards) or dark fabric, are not

placed over the insulation

and then left exposed. Dark-

coloured products can lead to

extremely high surface tem-

peratures, increasing the

potential for distortion of

rigid foam boards.

If STYROFOAM

™

Brand

Extruded Polystyrene Foam

Insulation is already installed,

cover it with a white opaque

polyethylene film to protect it

during the delay. Otherwise,

schedule the insulation instal-

lation for a time when the

entire installation process

can be completed in a timely

manner.