Prepare for post sleeves, Measure, mark & drill for brackets, Install brackets – AZEK Straight Rail User Manual

Page 2: Hardware, Parts tools required, Straight rail installation guidelines for, Important, Page 2, Top retainer, Bottom rail

(1) Handrail

Hardware

1

Parts

Tools Required

Pencil

Measuring

Tape

Drill

Recommended:

Impact Driver

Mitre Saw

fitted with a

high tooth

count finish

carpentry blade

1/8”

Drill

Bit

5/16”

Drill

Bit

(2) Top Rail

Straight Bracket

(2) Threaded

Plates

(2) Spring Clip Threaded

Plate Retainer

(2) Bottom Bracket

Base

(2) Bottom Bracket

Flange + Set Screw

.

(5) 1” #8 Wood

Screws

(8) 5/8” #10 Machine

Screws

(1) Spring Clip

Installation Tool

Trademark Profiles Shown

Throughout Instructions

Balusters

(13) 6’ Kit or (18) 8’ Kit

US:

(1) 4 3/8”

Center Support

Canada:

(1) 2 3/8”

Center Support

Premier

Top Rail

Reserve

Top Rail

(1) Top Retainer

(1) Bottom Rail

Premier

Bottom

Rail

Reserve

Bottom

Rail

(1) 3/16” Allen Key

(1) T-25 Bit

(2) Baluster Swing

Brackets

(1) Center Support

Bracket

Baluster Screws

(28) 6’ Kit

(38) 8’ Kit

(8) 2 1/2” #10 Wood

Screws

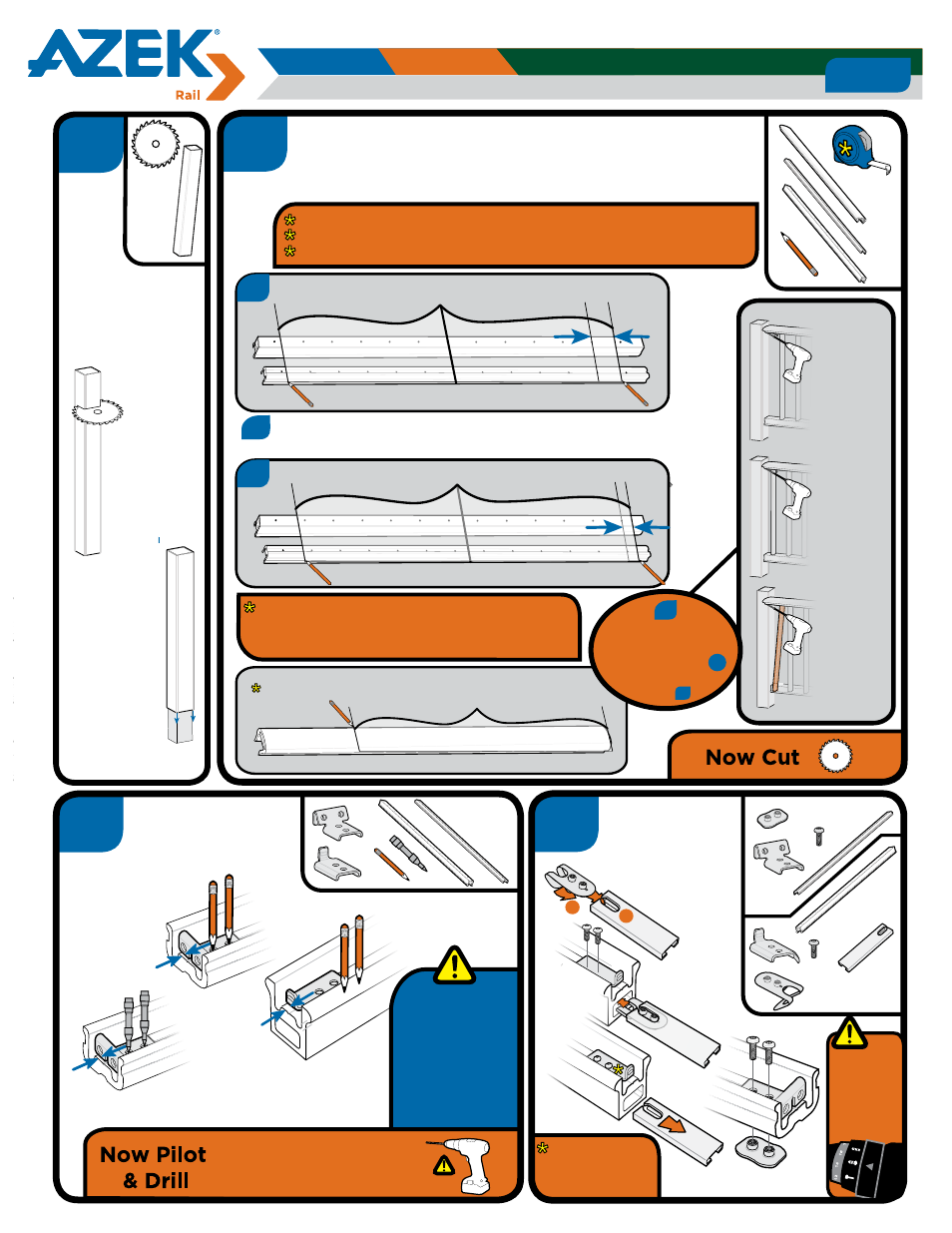

Prepare for

Post Sleeves

3/16”

Drill

Bit

• The 4 x 4 should be completely “boxed in” around all 4 corners of the

firmest attachment.

• Make sure posts are level and plumb.

• If post is twisted or oversized, trim as necessary so post sleeve slides

easily over post. (Do not force sleeve over post)

• Post sleeves may also be used over wood posts installed with Surface

Mount Bracket or over Tallboy Surface Mount Bracket.

• Post sleeves should not be notched for installation.

• If installing using a Surface Mount Bracket or Tallboy Surface Mount

Bracket, please refer to those specific installation instructions.

• IMPORTANT: Must check with local building code for proper installation

of wood post and decking attachment.

WARNING: Post sleeves are not designed to be used in

structural applications. Therefore, they should not be used

where they may be subject to weight bearing applications

such as supports for a roof of a porch or deck.

IMPORTANT

Make sure that the

DRIVE TOOL/DRILL

is configured or set

to use the SCREW

setting when driving

and/or tightening all

FASTENERS.

STRAIGHT RAIL INSTALLATION GUIDELINES for

AZEK Premier

AZEK Trademark

AZEK Reserve

Page 2

© 2013 AZEK Building Products. All rights reserved

Top Retainer

1

16

1

16

Hand Rail can be cut from either end

2

3

Remove install-

ation tool before

fully tightening

bracket screws

5

Top Retainer

Bottom Rail

When

drilling holes

for brackets,

do not drill

through top

surface of

bottom rail.

Measure, Mark

& Drill for

Brackets

Mark Bracket

1/16” from end

of Retainer

Pilot with 1/8” Drill Bit

Drill with 5/16“ Drill Bit

Mark Bracket

1/8” from end

of Bottom Rail

Consideration:

For Aluminum Top Retainer

use automatic center punch.

Cut Post

Sleeves

Measure & Mark Top Retainer, Bottom

Rail, & Handrail Ensuring Proper Hole

Spacing .... And Cut

Cut

Post Sleeve

minimum 2”

longer than

desired railing

height

Do not

force the

Post Sleeve

over the 4 x 4

as it may

eventually lead

to a crack or

split

X is

greater

than 3 1/8”,

NO

Swing

Bracket

Required

X is

less than

3 1/8”,

Swing

Bracket

IS

Required

Swing

Bracket

In Use

b

Rail Center Between Holes

X

a

Rail Center On Hole

If X is greater than 4 3/8”, Composite Baluster spacing will not meet Code.

If X is greater than 4 1/8”, Metal Baluster spacing will not meet Code.

Shift Rail Center from (a) Center on Hole to (b) Center Between Holes.

a

X

b

If X is less than 3 1/8”,

use Baluster Swing

Brackets in Step

to allow access in

Step

6a

13

Ensure Posts are square and plumb

Take measurements between bottom of posts for more accurate rail length

Leave Handrail 1/16” longer than Top Retainer for a tight fit

4

X 2

X 2

Install

Brackets

Bottom Rail

Bottom

Rail

X 4

X 4

X 2

X 2

X 2

Spring Clip

Installation Tool

Top

Retainer

1

2

Close Spring

Clip and

insert into

Installation

Tool

X 2

Most building codes require that a 4” sphere shall

not pass through the rail at any point.

To comply with 4” sphere rule, a 6 ft. section must

be cut a minimum of 7/8”.

IMPORTANT

Make sure that

the DRIVE

TOOL/DRILL is

configured or set

to use the

SCREW setting

when driving

and/or tightening

all FASTENERS.