Versatile heat transfer systems, Gravity system, Liquid overfeed refrigeration system – Anco Eaglin A-E Votator User Manual

Page 10: Liquid / steam jacketing

10

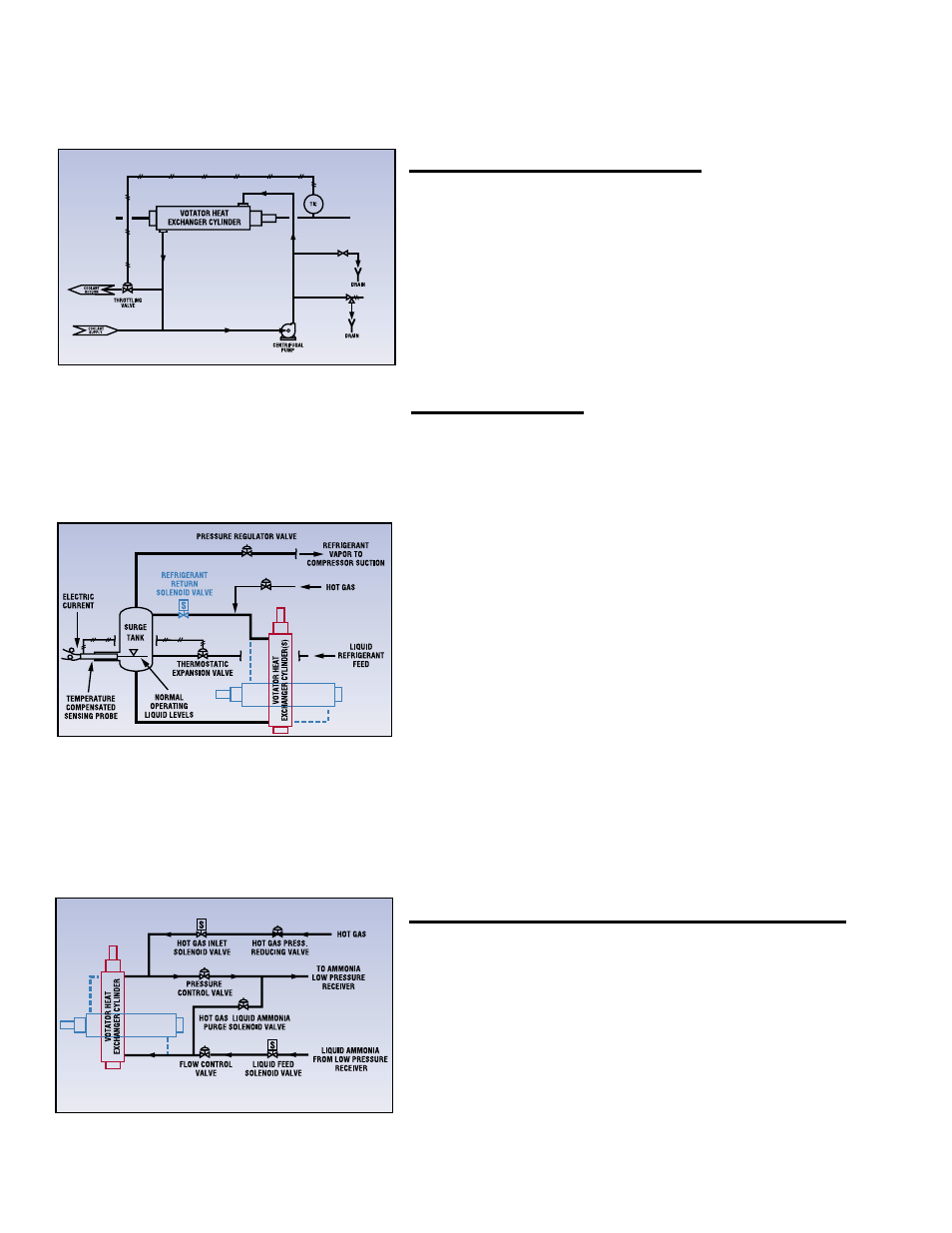

Gravity System

Liquid Overfeed Refrigeration System

Brine Water Steam

Gravity System

In the gravity refrigeration system, liquid refrigerant flows from a

receiver in the compressor plant to a surge drum installed above

the Votator

®

II or the Votator

®

II Extra Heavy Duty. A modulating

thermostatically controlled expansion valve automatically maintains

the correct refrigerant level in this vessel. Gravity forces the

refrigerant into the cooling jacket, where product heat vaporizes a

portion of the liquid and reduces the bulk density of the remainder.

The flow of vapor and this density difference combine to create

the classic “thermosyphon effect,” which forces liquid refrigerant

to circulate from the surge drum to the cooler. A regulating valve

controls the pressure in the surge drum and, consequently, the

temperature of the refrigerant in the cooling cylinder. Make-

up liquid enters through the level control and the entire cycle

continues. Individual surge drums can be provided for each

cooling cylinder or a single drum can be used for two cylinders.

The gravity system protects against freeze-up through an

instantaneous current relay system. Optional hot gas controls also

can be provided for freeze-up protection and to assist in removing

refrigerant for pump down.

Liquid Overfeed Refrigeration System

Liquid Overfeed (LOF) is available on the Votator

®

II and the

Votator

®

II Extra Heavy Duty. It is a proven direct expansion

concept in which only 25-35% of the liquid refrigerant flowing to

the heat exchanger is actually vaporized. A large low pressure

receiver replaces individual surge drums. This receiver, normally

located in the compressor plant, is designed to separate the vapor

from the circulated liquid. Waukesha Cherry-Burrell has designed

many scraped surface heat exchangers for operating with Liquid

Overfeed refrigeration. Overload protection against freeze-up is

included and hot gas systems can be provided.

Liquid / Steam Jacketing

When using a liquid heat transfer medium, it is necessary

to maintain a high flow rate for optimum efficiency. This is

accomplished by using a centrifugal pump to maintain a constant

media flow. A controller monitors the product temperature out of

the Votator

®

II heat exchanger and allows liquid media from the

supply to be introduced into the loop as required

Versatile Heat Transfer Systems