Anco Eaglin A-E 1600 Steam Tube Dryer User Manual

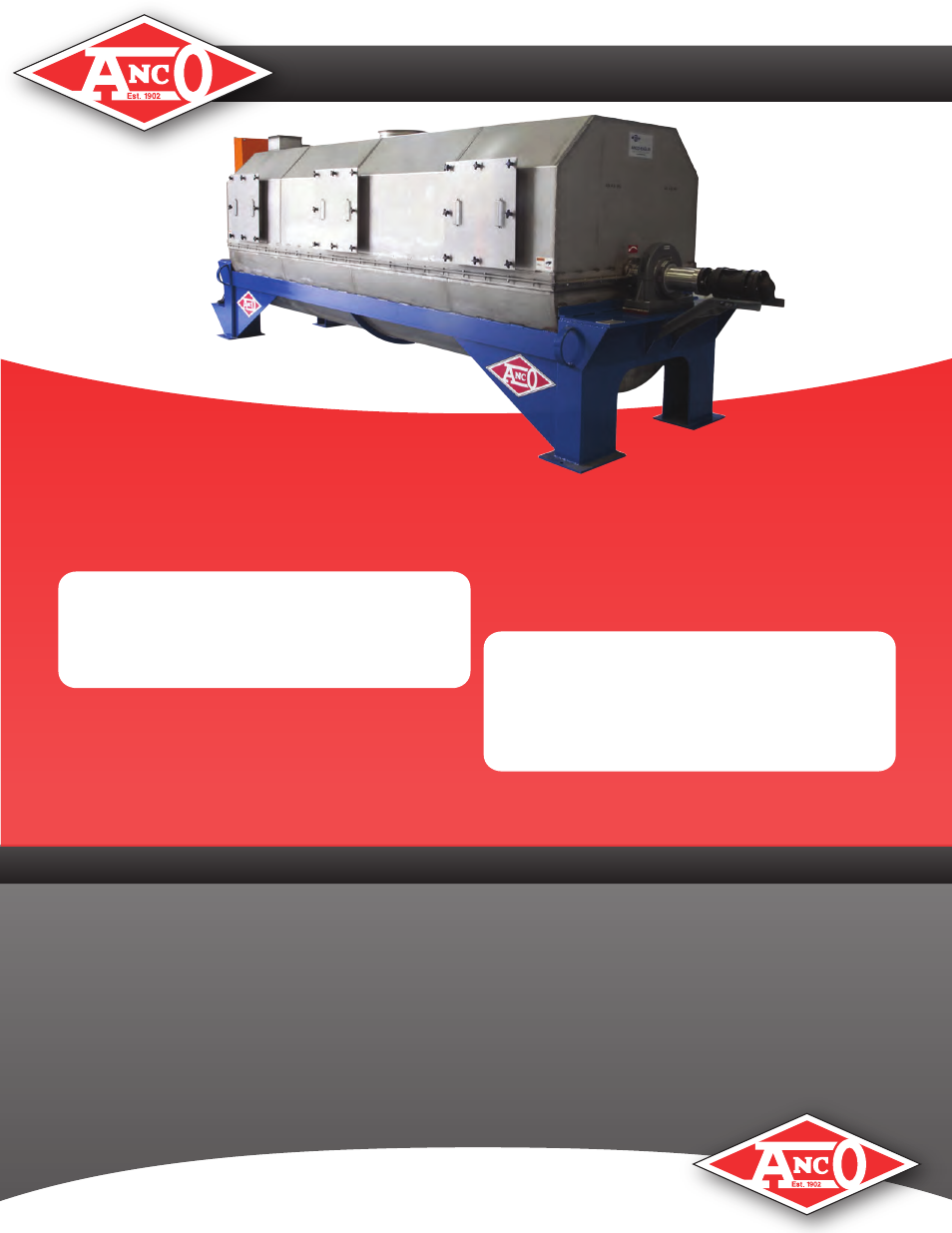

1600 continuous rotary steam tube drier

1600 Continuous Rotary Steam Tube Drier

ANCO-EAGLIN, Inc. 1420 Lorraine Avenue High Point, NC 27263

www.ancoeaglin.com | 336-855-7800 | [email protected]

STANDARD FEATURES

•

125 PSIG pressure rating for the rotating tube bundle.

•

Construction to ASME Code Section VII Division 1.

•

Greater heat transfer surface area and surface area flexibility.

•

Special diameter stainless steel steam tubes with increased

spacing reduces clogging from unwanted debris.

•

Heavy-duty cold rolled shaft attached to SKF bearings for

support rotating tube bundle.

•

Shell housing and sturdy product scooping plates fabricated

from stainless steel.

•

Shaft mounted gearbox designed expressly for high

durability.

AUTOMATION

Combining electronic speed control of the Dryer infeed and

discharge with temperature, pressure and load sensors

optimum performance can be achieved. For higher levels of

safety and automation the various monitoring points can be

upgraded into a PLC system.

VAPOR CONDENSING

ANCO-EAGLIN can provide a variety of options for

condensing the process vapors produced by the 1600 Drier.

The choices include:

•

Direct Contact Condenser

•

Indirect Heat Recovery Condenser

•

Fin Air Cooled

DEPENDABILITY

ANCO has been providing innovative and commonsense

solutions to the reclamation industry for more than 90 years.

The ANCO® model 1600 Rotary Steam Tube Dryer is designed

specially to dry poultry feathers, blood and hog hair. When

used in conjunction with traditional ANCO Batch Cookers

and Continuous Hydrolyzers, customers will save in

production time, steam demand and electrical consumption.

The Dryer is well suited for other types of free

flowing/granular materials such as chemicals, brewery waste

and minerals. Its compact design makes it an easy and

efficient way to upgrade from older evaporation equipment.

For example the 1600 Dryer takes up about the same floor

space as an older style unit while providing almost double

the heat transfer area.

RENDERING DIVERSITY

ANCO-EAGLIN couples the best component fit for your

material-processing needs with our ability and expertise.

Whether it’s beef or hog offal, blood drying, hair or feather

hydrolyzing, packing house material, poultry offal or dead

stock, ANCO® can handle them all, as it has for 90 years.

DESIGN

The model 1600 Dryer consists of multiple steam tubes

arranged in a rotating tube bundle. The steam tubes are

permanently attached to the rotating head and are

permitted to expand and contract with temperature

changes.

Steam is sent through a special rotating steam joint to a

rotating head and then into the tubes. Heat is exchanged

between the steam tubes and the wet product causing

moisture to evaporate and the steam to condense.

Condensate drains back through the tubes into special

collection chambers in the rotating head and passes out

through the rotating steam joint back to the steam boiler

system.