American Dryer Corp. SL20 User Manual

Page 7

113191-2

5

Important

Make-up air must be provided from a source free of

dry cleaning solvent fumes. Make-up air that is

contaminated by dry cleaning solvent fumes will result in

irreparable damage to the motors and other dryer

components.

Note

Component failure due to dry cleaning solvent fumes

will void the warranty.

Exhaust Requirements _________________

Do not use a nonmetal flexible vent or a metal vent that is

smaller than 4-inches (10.2 cm) in diameter or exhaust hoods

with magnetic latches.

The dryer shall not be exhausted into any gas vent, chimney,

wall, ceiling or concealed space of a building.

Do not install flexible vent in enclosed walls, ceilings, or floors.

Important

Observe all governing codes and ordinances.

Exhaust your dryer to the outside. Moisture and lint indoors

may cause:

• Lint to gather around the dryer where it can be fuel for a

fire.

• Moisture damage to woodwork, furniture, paint, wallpaper,

carpet, etc.

• Housecleaning problems and health problems.

A 4-inch (10.2 cm) diameter vent is required. A rigid or flexible

metal vent must be used. Do not use a plastic or a foil covered

vent.

Use a heavy metal vent. Do not use a plastic or metal foil

vent. A rigid metal vent is recommended to prevent crushing

and kinking. A flexible metal vent must be fully extended and

supported when the dryer is in its final position. Remove

excess flexible vent to avoid sagging and kinking that may

result in reduced airflow.

If using an existing exhaust system, clean lint from entire

length of system. Make sure exhaust hood is not plugged

with lint. Replace any vinyl or metallized plastic foil vent with

rigid metal or flexible metal vent.

Use duct tape to seal all joints. Do not use screws or other

fastening devices that extend into the interior of the vent to

secure vent.

Service check: Back pressure in any exhaust system used

must be no less than 0 and must not exceed 0.6 inches

(1.49 mb) water column (W.C.) measured with an incline

manometer at the point that exhaust vent connects to the

dryer.

Important

It is recommended that exhaust or booster fans not

be used in the exhaust ductwork system.

Note

As per the National Fuel Gas Code, “Exhaust ducts

for type 2 clothes dryers shall be constructed of sheet

metal or other noncombustible material. Such ducts shall

be equivalent in strength and corrosion resistance to ducts

m a d e o f g a l v a n i z e d s h e e t s t e e l n o t l e s s t h a n

0.0195-inches (26 gauge [0.05 mm]) thick.”

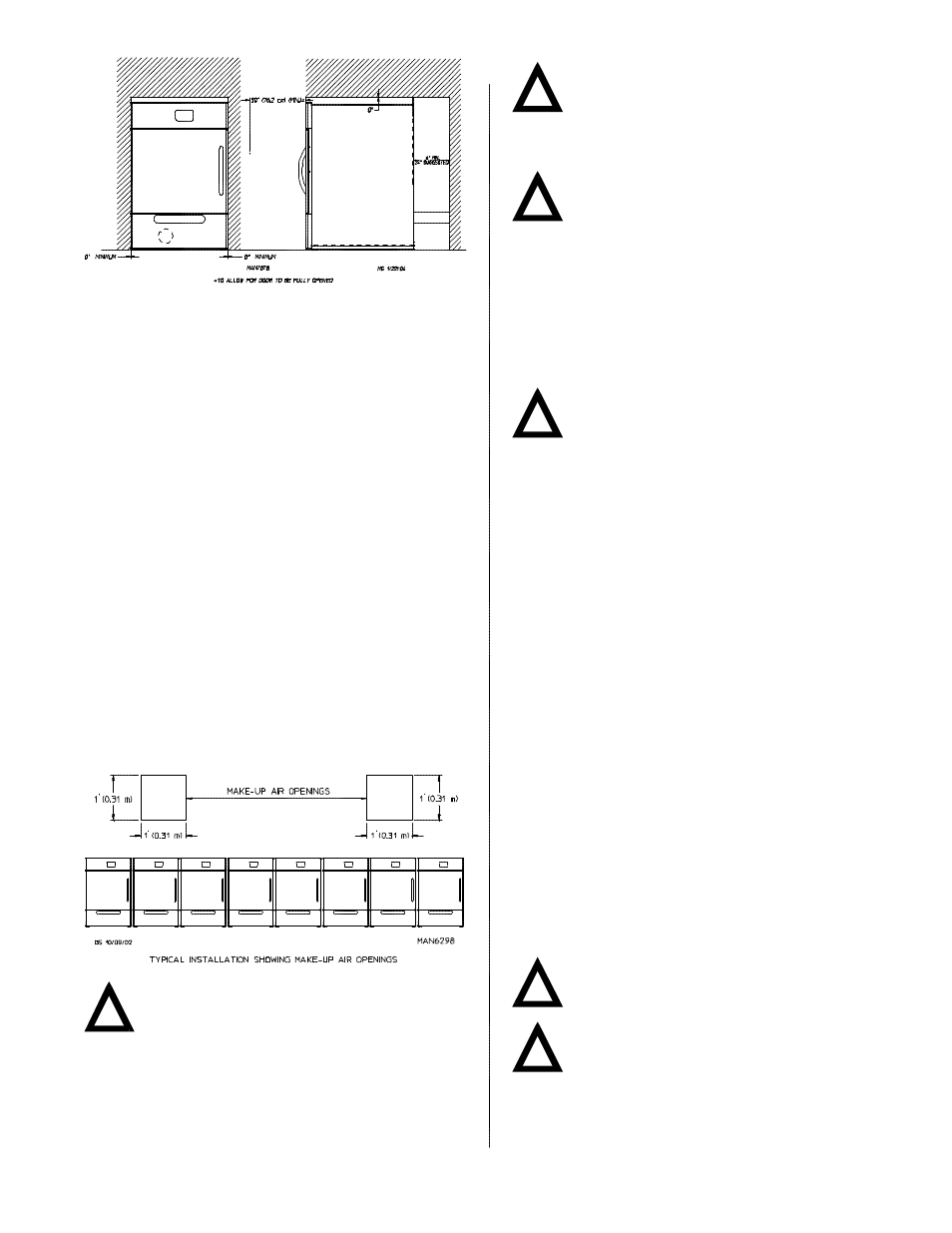

If a closet door is installed: unobstructed air openings are

required. The air openings shall be located 3-inches

(7.62 cm) from the lower opening (above floor level) and upper

opening (below ceiling). The total free area of the air openings

in the door shall not be less than 96 square inches

(619.35 square centimeters). Louvered doors with equivalent

air openings are acceptable.

No other fuel-burning appliance shall be installed in the

same closet as the dryer.

Fresh Air Supply Requirements ________

The air supply (make-up air) must be given careful

consideration to ensure proper performance of each dryer.

An unrestricted source of air is necessary for each dryer. As

a general rule, an unrestricted air entrance from the outdoors

(atmosphere) of a minimum of 1/3 square feet (0.031 square

meters) is required for each dryer. If registers or louvers are

installed over the openings, then the area must be increased.

It is not necessary to have a separate make-up air opening

for each dryer. Common make-up air openings are

acceptable. However, they must be set up in such a manner

that the make-up air is distributed equally to the dryers. The

dryer must be installed with provisions for adequate

combustion and make-up air supply.

EXAMPLE: For a bank of eight (8) dryers, two (2)

unrestricted openings measuring 1 foot by 1 foot (0.31

meters by 0.31 meters), (1 square foot [0.93 square

meters]) are acceptable.

Important

Make-up air openings should not be located in an

area directly near where exhaust vents exit the

building.

Allowances must be made for remote or constricting

passageways or where dryers are located at excessive

altitudes or predominantly low pressure areas.

!

!

!

!

!

!