American Dryer Corp. SL20 User Manual

Page 15

113191-2

13

D

ATA

L

ABEL

I

NFORMATION

_______

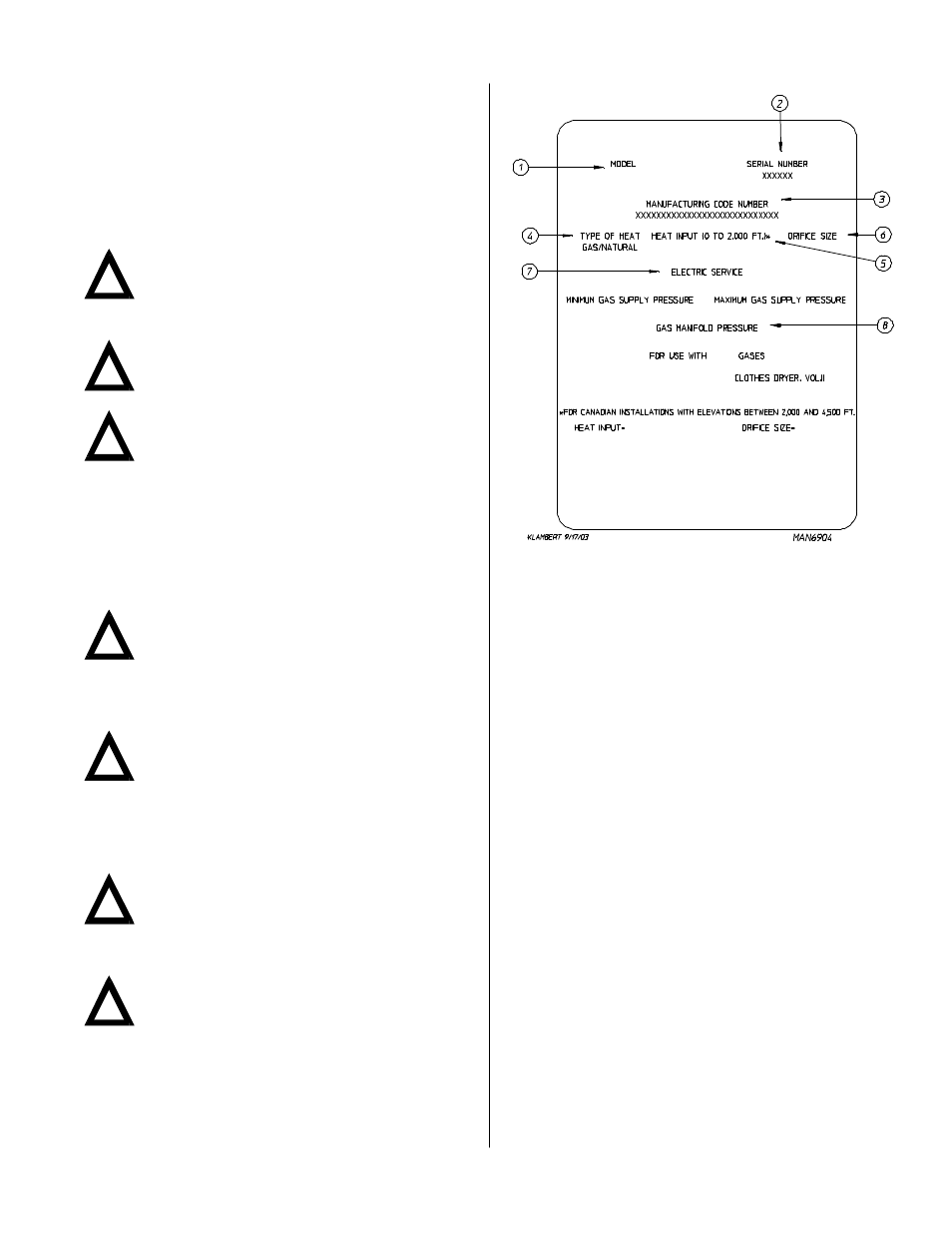

When contacting American Dryer Corporation, certain

information is required to ensure proper service/parts

information from ADC. This information is on the data label

that is affixed to the rear upper left back area of the dryer,

which can be viewed either through the openings in the dryer’s

back panel/guard, or by removing this back panel/guard.

When contacting ADC, please have the model number and

serial number available.

1. MODEL NUMBER

The model number is an ADC number, which describes the size

of the dryer and the type of heat (gas, electric, or steam).

2. SERIAL NUMBER

The serial number allows ADC to gather information on your

particular dryer.

3. MANUFACTURING CODE NUMBER

The manufacturing code number is a number issued by ADC,

which describes all possible options on your particular model.

4. TYPE OF HEAT

This describes the type of heat for your particular dryer: gas

(either natural gas or liquid propane [L.P.] gas), electric, or

steam.

5. HEAT INPUT (FOR GAS DRYERS)

This describes the heat input in British Thermal Units per Hour

(Btu/hr).

6. ORIFICE SIZE (FOR GAS DRYERS)

Gives the number drill size used.

7. ELECTRIC SERVICE

This describes the electric service for your particular model.

8. GAS MANIFOLD PRESSURE (FOR GAS DRYERS)

This describes the manifold pressure taken at the gas valve tap.

R

OUTINE

M

AINTENANCE

_________

A program and/or schedule should be established for

periodic inspection, cleaning, and removal of lint from various

areas of the dryer, as well as throughout the ductwork system.

The frequency of cleaning can best be determined from

experience at each location. Maximum operating efficiency

is dependent upon proper air circulation. The accumulation

of lint can restrict this airflow. If the guidelines in this section

are met, an ADC dryer will provide many years of efficient,

trouble free, and most importantly, safe operation.

Warning

Lint from most fabrics is highly combustible. The

accumulation of lint can create a potential fire hazard.

Keep dryer area clear and free from combustible

materials, gasoline, and other flammable vapors and liquids.

Note

Suggested time intervals shown are for average

usage, which is considered six (6) to eight (8)

operational (running) hours per day.

Important

Dryer produces combustible lint and must be

exhausted to the outdoors. Every 6 months, inspect

the exhaust ducting and remove any lint buildup.

Suggested Cleaning Schedule _________

Every Third Or Fourth Load

Clean the lint drawer/tray every third or fourth load. A clogged

lint drawer/tray will cause poor dryer performance. The lint

drawer/tray is located on the lower front of the dryer. Inspect

lint screen and replace if torn.

Note

The frequency of cleaning the lint drawer/tray can best

be determined from experience at each location.

Weekly

Clean lint accumulation from lint chamber, thermostat, and

temperature high-limit sensor area.

Warning

To avoid the hazard of electrical shock, discontinue

electrical supply to the dryer.

90 Days

Inspect and remove lint accumulation in customer furnished

exhaust ductwork system from dryer’s internal exhaust

ducting.

Warning

The accumulation of lint in the exhaust ductwork can

create a potential fire hazard.

Do not obstruct the flow of combustion and

ventilation air.

Note

When cleaning the dryer cabinet(s), avoid using harsh

abrasives. A product intended for the cleaning of

appliances is recommended.

!

!

!

!

!

!

!