Samsung SCX-6555N-XBG User Manual

Page 101

101

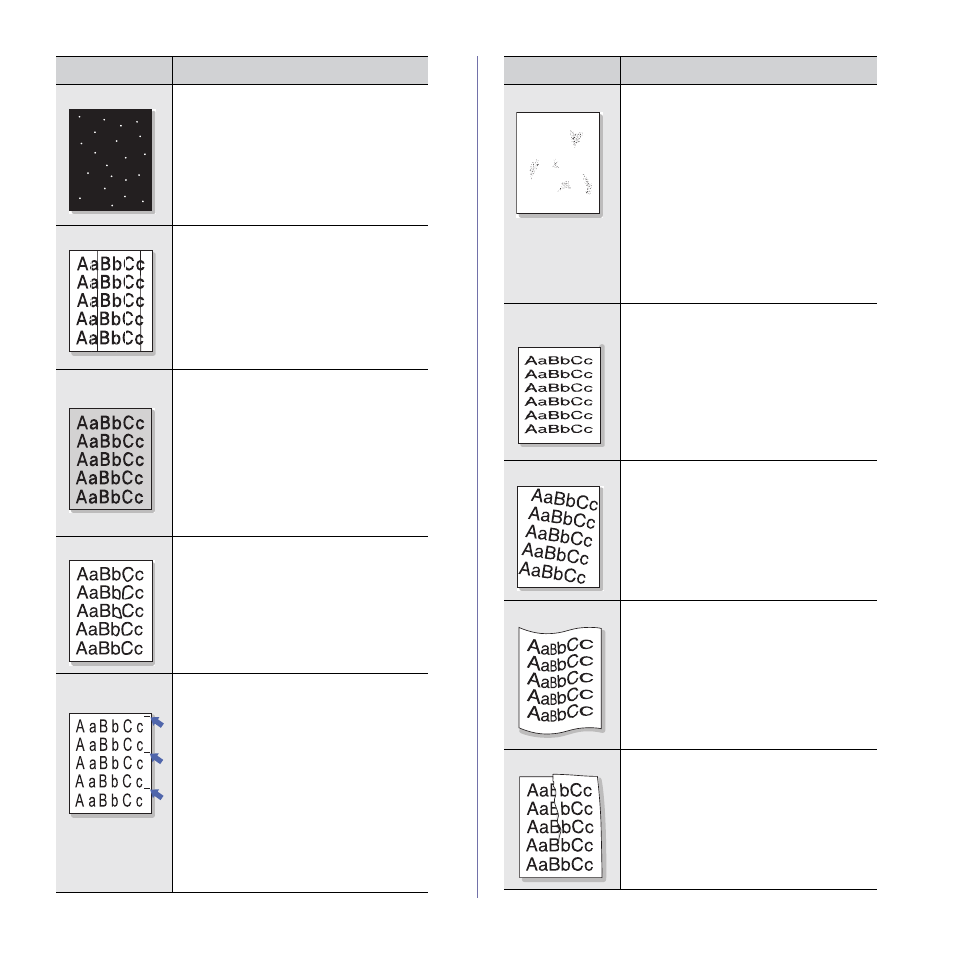

White Spots

White spots appears on the page:

•

The paper is too rough and a lot of dirt from

a paper falls to the inner devices within the

machine, so the transfer roller may be dirty.

Clean the inside of your machine. (See "In

the multi-purpose tray" on page96) Contact

a service representative.

•

The paper path may need cleaning.

Contact a service representative.

Vertical lines

If black vertical streaks appear on the page:

•

The surface(drum part) of the imaging unit

inside the machine has probably been

scratched. Remove the imaging unit and

install a new one. (See "In the multi-

If white vertical streaks appear on the page:

•

The surface of the LSU part inside the

machine may be dirty. Clean the LSU.

Contact a service representative.

Color or Black

background

If the amount of background shading becomes

unacceptable:

•

Change to a lighter weight paper. (See "In

the multi-purpose tray" on page96)

•

Check the environmental conditions: very

dry conditions (low humidity) or a high level

of humidity (higher than 80% RH) can

increase the amount of background

shading.

•

Remove the old imaging unit and then,

install a new one. (See "In the multi-

Toner smear

•

Clean the inside of the machine. Contact a

service representative.

•

Check the paper type and quality. (See "In

the multi-purpose tray" on page96)

•

Remove the imaging unit and then, install a

new one. (See "In the multi-purpose tray" on

Vertical repetitive

defects

If marks repeatedly appear on the printed side

of the page at even intervals:

•

The imaging unit may be damaged. If a

repetitive mark occurs on the page, run a

cleaning sheet through several times to

clean the cartridge; contact a service

representative. After the printout, if you still

have the same problems, remove the

imaging unit and then, install a new one.

(See "In the multi-purpose tray" on page96)

•

Parts of the machine may have toner on

them. If the defects occur on the back of

the page, the problem will likely correct

itself after a few more pages.

•

The fusing assembly may be damaged.

Contact a service representative.

CONDITION

SUGGESTED SOLUTIONS

Background scatter

Background scatter results from bits of toner

randomly distributed on the printed page.

•

The paper may be too damp. Try printing

with a different batch of paper. Do not open

packages of paper until necessary so that

the paper does not absorb too much

moisture.

•

If background scatter occurs on an

envelope, change the printing layout to

avoid printing over areas that have

overlapping seams on the reverse side.

Printing on seams can cause problems.

•

If background scatter covers the entire

surface area of a printed page, adjust the

print resolution through your software

application or in printer properties.

Misformed

characters

•

If characters are improperly formed and

producing hollow images, the paper stock

may be too slick. Try different paper. (See

"In the multi-purpose tray" on page96)

•

If characters are improperly formed and

producing a wavy effect, the scanner unit

may need service. Contact a service

representative.

Page skew

•

Ensure that the paper is loaded properly.

•

Check the paper type and quality. (See "In

the multi-purpose tray" on page96)

•

Ensure that the paper or other material is

loaded correctly and the guides are not too

tight or too loose against the paper stack.

Curl or wave

•

Ensure that the paper is loaded properly.

•

Check the paper type and quality. Both high

temperature and humidity can cause paper

curl. (See "In the multi-purpose tray" on

•

Turn the stack of paper over in the tray. Also

try rotating the paper 180° in the tray.

Wrinkles or creases •

Ensure that the paper is loaded properly.

•

Check the paper type and quality. (See "In

the multi-purpose tray" on page96)

•

Turn the stack of paper over in the tray. Also

try rotating the paper 180° in the tray.

CONDITION

SUGGESTED SOLUTIONS

A