1 wind speed, Maintenance, 1 suggested maintenance schedules – Campbell Scientific 014A Met One Wind Speed Sensor User Manual

Page 19: 1 6 to 12 month periodic service, Wind speed, Suggested maintenance schedules, 6 to 12 month periodic service, 3. wind speed multiplier

Met One 014A Wind Speed Sensor

Short Cut cannot edit programs after they are imported and edited

in CRBasic Editor.

A Short Cut tutorial is available in Section 4.2, Use SCWin to Program

Datalogger and Generate Wiring Diagram. If you wish to import Short Cut

code into either CRBasic Editor or Edlog to create or add to a customized

program, follow the procedure in Appendix A.1, Importing Short Cut Code

into a Program Editor. Programming basics for CRBasic and Edlog

dataloggers are provided in the following sections. Complete program

examples for select dataloggers can be found in Appendix B, Example

Programs.

7.4.1 Wind Speed

Wind speed is typically measured with a pulse count instruction, using the

switch closure configuration. For dataloggers programmed with Edlog, specify

configuration code 22 to output frequency in hertz.

If using a control port, see Appendix B.2, Control Port Example Program.

The expression for wind speed (U) is:

U = MX + B

where

M = multiplier

X = number of pulses per second (hertz)

B = offset

TABLE 7-3 lists the multipliers (M) and offsets (Off) to obtain meters/second

or miles/hour when the pulse count instruction is configured to output the result

in Hz.

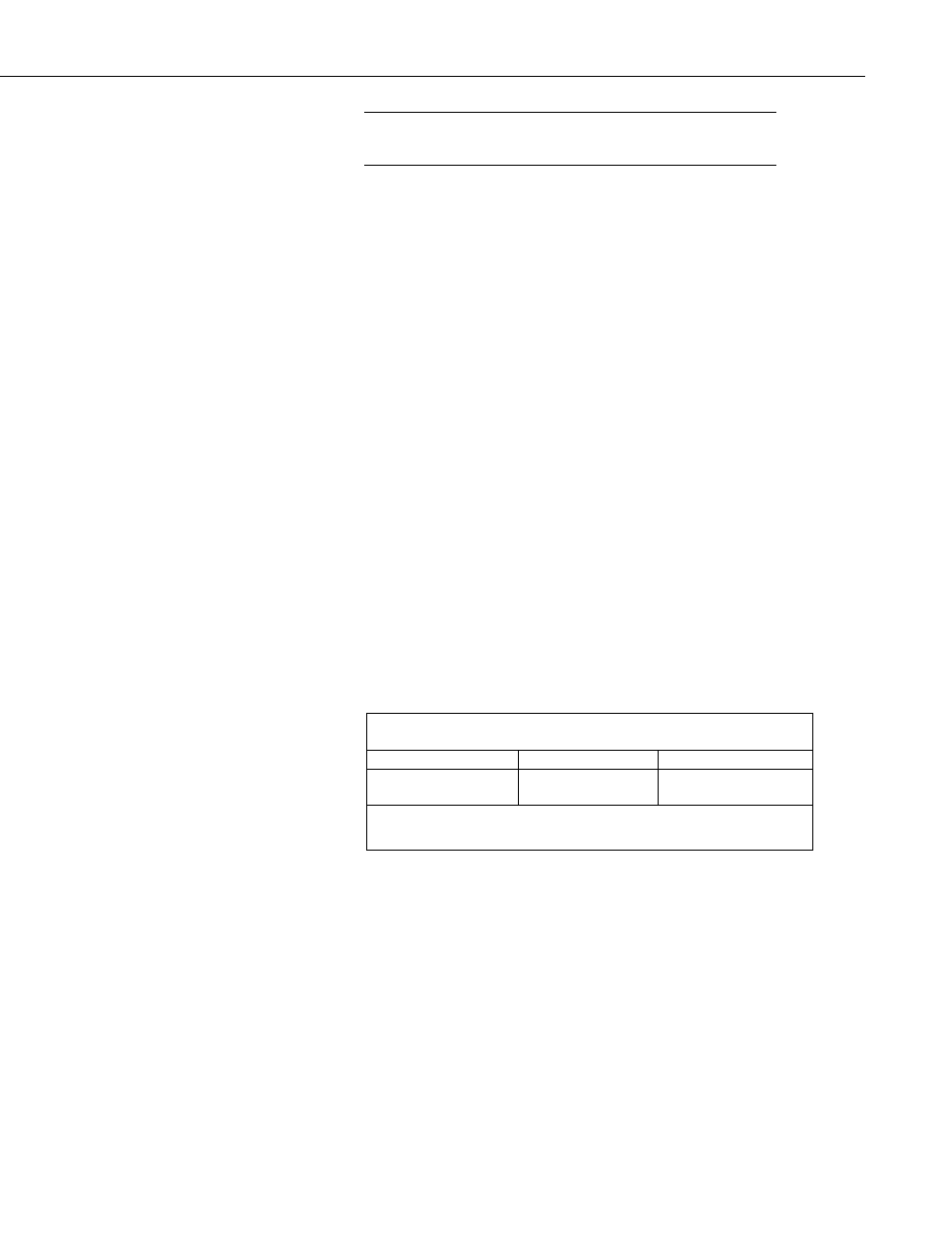

TABLE 7-3. Wind Speed Multiplier*

Model

Meters/Second

Miles/Hour

014A

M = 0.8000

Off = 0.447

M = 1.789

Off = 1.0

*When configured to output counts, the above multiplier is divided

by the execution interval in seconds

8. Maintenance

8.1 Suggested Maintenance Schedules

8.1.1 6 to 12 Month Periodic Service

Visually inspect the anemometer cups for cracks and breaks, and make sure

that each arm is securely attached to the cup assembly hub. Also check to see

that the vent hole, located at the base of the sensor, is unobstructed.

Special caution is advised under adverse conditions of high winds, heat, and/or

sandy areas. Look for abrupt stopping of the cup assembly with slow cup

rotation. If this occurs, the bearings may need to be replaced.

NOTE

11