Type of gas, Vii initial start-up – Midco G69B User Manual

Page 7

20

350

550

730

1150

1100

1730

2100

2500

2500

-7-

CAUTION: Do not exceed maximum rated capacity

of burner model - See Tables 1 and 2.

Capacities shown are for total pressure drop of .3"W.C. For

higher permissible pressure drops consult your fuel

supplier.

Source: Gas Engineers HandbookÑ1974

TABLE 3

Schedule 40 Pipe Capacity Chart

Before gas is introduced to the system, a check must be

made to see that there are no open fittings and to make

sure the burner main and pilot manual valves are closed.

After checking above, purge the gas line up to the burner

inlet. Purging the air from the gas supply line at this step

will expedite the first light-off.

CAUTION: Purge outside the building. Do not

purge into the gas utilization equipment combustion

chamber.

Gas Supply

Pipe Size

N.P.T.

1"

1-1Ъ4"

1-1Ъ2"

2"

2 -1Ъ2"

3"

Type of

Gas

Natural

Propane

Natural

Propane

Natural

Propane

Natural

Propane

Natural

Propane

Natural

Propane

APPROXIMATE CAPACITY-MBH

Length of Pipe Ñ Feet

40

385

500

785

760

1200

1450

2280

2300

2500

2500

60

300

400

630

610

960

1150

1800

1850

2500

2500

100

300

480

460

725

870

1370

1400

2200

2500

2500

200

330

320

500

610

960

980

1550

1700

2500

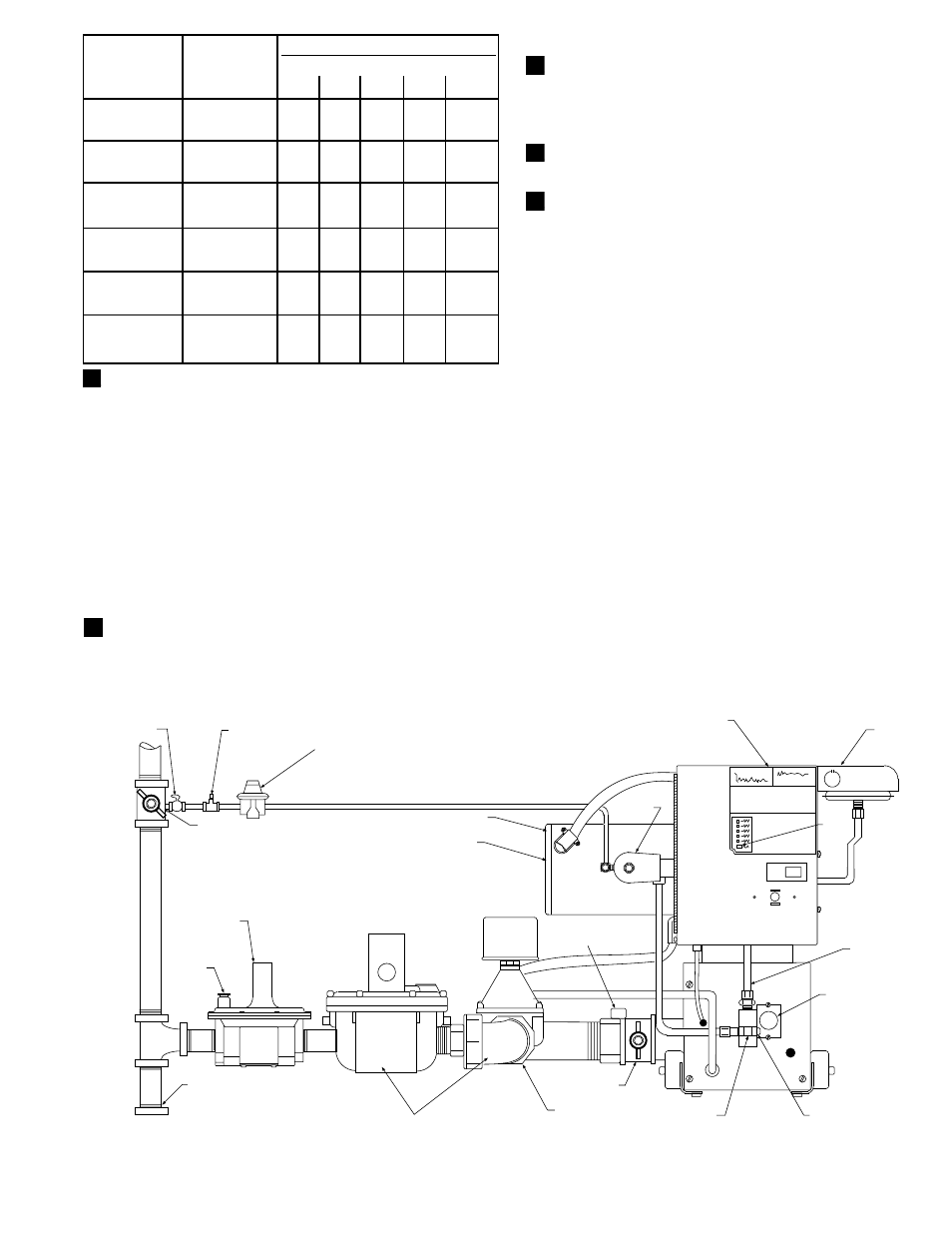

MAIN REGULATOR

MAIN REGULATOR

VENT

PILOT MANUAL

VALVE

BALL

VALVE

PILOT

REGULATOR

BLOWER

MOTOR

MANUAL MOTOR RESET

BUTTON

(MAY HAVE AUTO RESET)

MANIFOLD PRESSURE

TAP

DRIP LEG

REDUNDANT MAIN

AUTOMATIC VALVES

BF INPUT ADJUSTER

(HIDDEN)

BALL VALVE

PILOT SOLENOID

VALVE

PILOT MIXING

TEE

PILOT

PRESSURE TAP

PEEP SIGHT

PILOT AIR

TUBE

RESET

BUTTON

BLOWER

AIR

SWITCH

FLAME SAFEGUARD

CONTROL

INLET PRESSURE TAP

1/4 TEE

1/4 PLUG

FIGURE 11

Piping Connections

VII

INITIAL START-UP

WARNING: Repeated unsuccessful attempts to

light may result in accumulated gases in gas

utilization equipment and chimney. To prevent these

gases from reaching an explosive level, periodically

purge the gas utilization equipment.

CAUTION: All cover plates, guards, and

enclosures must be maintained in place at all times

except during maintenance and servicing.

CAUTION:

Optional equipment and/or special

limit controls such as high/low gas pressure switches

can alter the start-up procedure. See Section XIV-

SPECIAL EQUIPMENT.

1.

Check the piping for leaks. A quick way to do this is to

close the main manual shut-off valve and manual

pilot valve, then turn on the gas pressure to the gas

supply line and observe the meter test dial. There

should be no movement of the test dial hand for at

least twenty minutes. All other gas appliances must be

completely shut off during this test (including pilots). If

a leak is detected it should be located with a soap

suds test. Test the main automatic valve for tightness.

(see Section XII for instructions). The ball valve is

intended to be open at all times except when testing

for main valve leakage. The Main Manual Shut-Off

Valve must be used for manual gas shut-off.

2.

Make sure that the burner main and pilot gas lines are

completely purged of air. Do not purge into the

combustion chamber. Purge outside the building.

3.

Make sure the burner power switch is off, manual

valve is closed, pilot manual valve is closed,

motor is free to rotate, and flame safeguard reset

button is set.

4.

Make the proper settings on all limit controls and set

controller to call for heat.

5.

Set blower air shutter wide open.