Part 1 installation, Specifications, I ventilation – Midco G69B User Manual

Page 2

NATURAL

5.0" W.C.

7.0" W.C.

6.7" W.C.

7.5" W.C.

INLET GAS PRESSURE

REQUIRED2

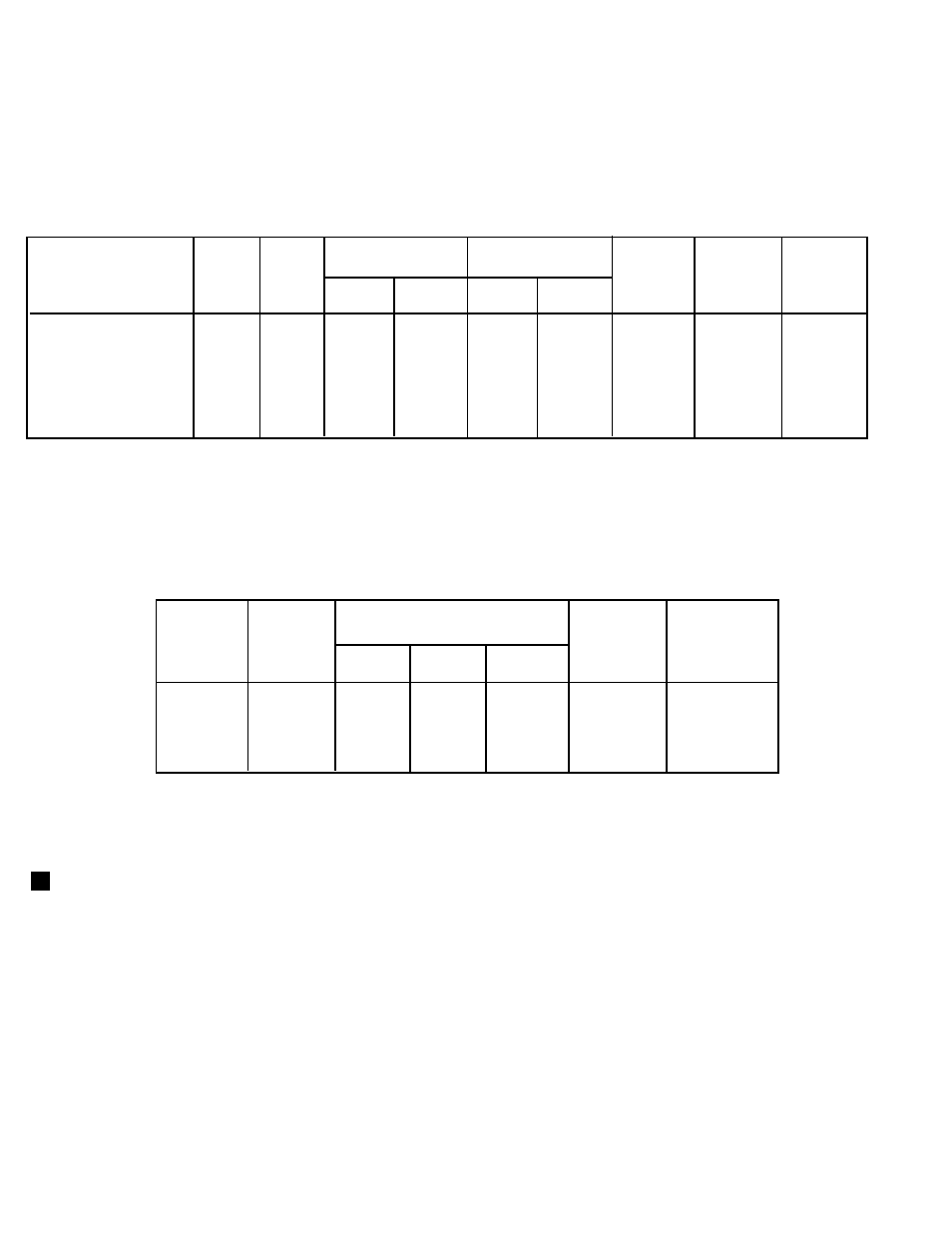

TABLE 2

Maximum Capacity at Specified Back Pressures

PART 1

INSTALLATION

CAUTION: Unipower GB -Series are not intended

for outdoor installation and must be protected from

excessive moisture. Provide adequate clearance for

service and proper operation.

I VENTILATION

Open basements will generally allow sufficient air

infiltration, so special provisions will seldom be required. If

the heating plant is located in a separate furnace room or

in an unusually tight basement, permanent means must be

provided to supply an ample volume of fresh air for

combustion and boiler room ventilation. A direct opening

to the outside air should be provided sized on the basis of

1/2 square foot of free opening for each 1,000,000 BTU of

burner rating when the vent connector is equipped with a

barometric draft control, 1 1/2 square feet when equipped

with a draft hood. If the ventilation opening is screened, it

should be of 1-1/4" mesh. The opening should be located

at least six feet over ground level to prevent accidental

obstruction. If a direct opening to the outside air is not

available, an ample sized air duct can be run to the

nearest outside air source; or, if practical, open stairwells

or building corridors connecting to an outside wall having a

ventilating opening can be used for this purpose, provided

that no possibility of accidental closure exists.

While the spark ignition pilot system performs successfully

under moderate or momentary back draft conditions, it is

not intended for operation under sustained reverse draft,

for example in a building with large ventilating fans but with

insufficient make-up air. Even if burner operation is

successful this condition must be corrected to prevent the

hazard of drawing flue gases into the building.

Consult your local gas company when doubt exists

concerning boiler room ventilation.

SPECIFICATIONS

BURNER STYLE...................................................................... Power Type

PILOT TYPE............................................................................. Intermittent, Spark Ignition

PILOT SAFETY........................................................................ Instantaneous Electronic Flame Safeguard

STANDARD VOLTAGE

CONTROLS (FIELD WIRING)...............................................120/1/60

MOTOR................................................................................. 115/1/60 (except G69B-115/230/1/60)

U.L. LISTED

NATURAL Gas

(1,000

BTU/cu. ft.)

G56B

G57B

G58B

G69B

PROPANE Gas

(2,500

BTU/cu. ft.)

G56BP

G57BP

G58BP

G69BP

Maximum

Input

1

MBTU/Hr.*

1000

1450

1800

2500

PROPANE

5.0" W.C.

5.0" W.C.

6.0" W.C.

8.0" W.C.

NATURAL

2.2" W.C.

4.1" W.C.

4.6" W.C.

4.2" W.C.

PROPANE

1.2" W.C.

2.6" W.C.

3.8" W.C.

3.3" W.C.

Minimum Input

3

MBTU/Hr.*

300

300

500

800

Motor HP

(3450 RPM)

1/6

1/3

1/2

3/4

Recom-

mended

Combustion

Chamber Size

42" x 18

"

48" x 21"

50" x 24"

60" x 27"

TABLE 1

Burner Specifications

1.

Values given based on +0.000" W.C. firebox pressure, altitudes to 2000 feet. Derate burner for altitudes over 2000

feet by 4% for each 1000 feet over sea level.

2.

Maximum inlet pressure both gases: 14" W.C. Refer to Section VI Piping for high pressure.

3.

Modulating and two-step burners are limited to a 3 to 1 turndown ratio.

4.

Manifold pressures are approximate and will vary slightly according to job condition. See Section VII para. 11.

5.

Pressures are based on 25% excess combustion air.

6.

SCFM = Standard Cubic Feet/Minute.

MODEL

G56B

G57B

G58B

G69B

MINIMUM

FIRING RATE

MBH*

300

300

500

800

0" W.C.

1075

1500

1850

2500

.25" W.C

.

950

1400

1750

2375

.5" W.C.

875

1325

1650

2275

MAXIMUM BACK

PRESSURE

IN " W.C.

0.7

0.8

1.0

1.0

MAXIMUM MBH* @

MAX. B.P.

700

1325

1400

2100

MAXIMUM CAPACITY IN MBH AT

COMB. CH. - BACK PRESSURE

* 1 MBH = 1,000 BTU/Hr.

MODEL

BURNER MANIFOLD

PRESSURE

1, 4, 5

-2-

Maximum

Air

SCFM

6

224

313

385

521