Midco G69B User Manual

Page 10

gas/air mixture is then discharged through the heat resistant

alloy flame retention pilot tip.

The spark rod is located on the center line of the pilot

and is arranged to arc to the inside of the central port.

Spark current is supplied by a spark generator to ignite

pilot gas.

The pilot regulator is factory set of an outlet pressure of

3 -1/2" W.C. for NATURAL gas and PROPANE, which will be

suitable for average conditions. Pressure can be varied to

suit particular job conditions. Do not increase orifice sizes

indiscriminately. Pilot troubles may be introduced by causing

the pilot to float and lose contact with the flamerod or flame

grounding area. Adjust the pilot per paragraph 7 of Section

VIII-Initial Start-Up.

Service of the pilot will generally consist only of inspection

and cleaning. Check that the pilot tip ports, air tube and

mixing tee are free of lint and dirt and that the pilot tip is free

of corrosion. Make sure that the air tube is re-inserted into

the blower housing pilot air tube hole. The spark insulator

and cable must be clean, dry and free from cracks and

abrasions. Make spark gap settings per Figure 15.

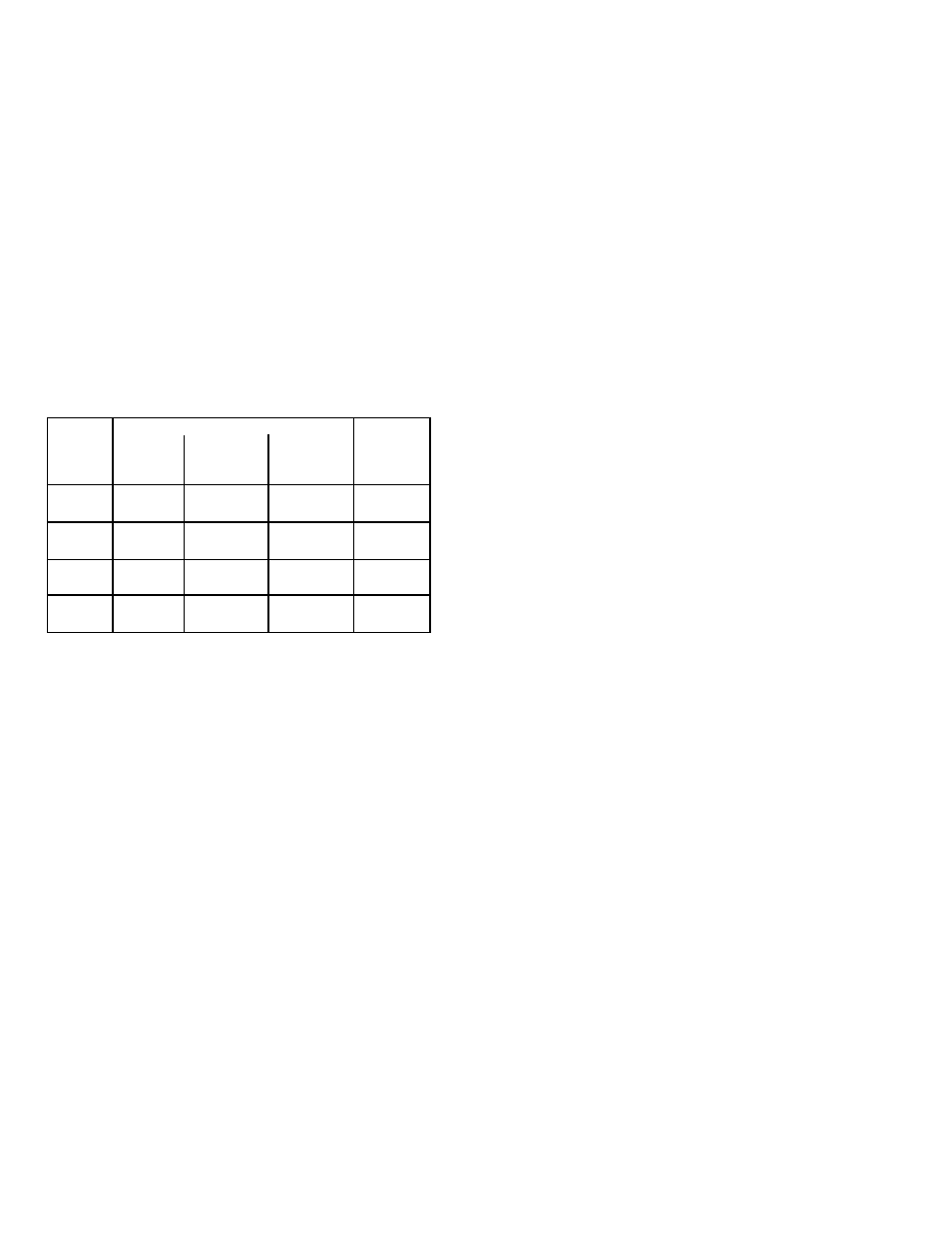

TABLE 5: Pilot Specifications

Proper operation of the flame safeguard depends on a

reliable current flow through the flamerod, pilot flame, and

flame grounding area. The flamerod must be free of any

contact with conductive burner parts. The insulator must be

clean, dry and free from cracks. While the rod is made of

heat resistant alloy, it may eventually deteriorate at the point

of flame contact and should be replaced if seriously

corroded. See Figure 15 for the proper alignment of the

flamerod. DO NOT BEND THE FLAMEROD TO REDUCE

THE DISTANCE FROM THE PILOT TIP.

X

BLOWER AND MOTOR

The blower functions to supply a constant and positive

supply of air for complete combustion. Air volume is

controlled by an adjustable shutter in the blower outlet. A

small supply of air is diverted ahead of the shutter for the

pilot and for operation of the blower air proving switch.

No routine service is necessary on the blower other than an

occasional cleaning of the blower wheel. If the blower wheel

must be replaced, be sure to check the replacement for

proper rotation. The concave sides of the blades must face

the blower outlet, and rotation of the wheel must be toward

the outlet. See Section VII pg. 8 para 6. The 3/4 HP single

phase motor used on the G69B burner uses a motor

switching relay to handle the motor load. All motors contain

integral motor overload protection, usually manual,

occasionally automatic reset.

Proof of blower operation is provided by a diaphragm air

-10-

switch, which must close its contacts and maintain them

closed when the blower is running. In case of

malfunction the air switch should be replaced.

XI

GAS PRESSURE REGULATOR

The gas pressure regulator is used to automatically

reduce and maintain an constant gas pressure to the

burner. To vary the outlet pressure, remove the seal cap

for access to the adjusting screw. Turning the screw

clockwise will increase outlet pressure,

counter-clockwise will decrease outlet pressure.

Maximum and minimum allowable gas pressures are

shown in Table 1. Because these regulators are of the

low pressure type with metal seats, leakage through the

seat will cause outlet pressure to rise equal to inlet

pressure during burner shutdown. Therefore do not

subject the burner to inlet pressures above those listed

(14"W.C.). For higher inlet pressures, See Section VI -

PIPING for instruction on installing alternate regulators.

The vent in the upper diaphragm case normally breathes

air but should be vented to the outside for protection in

the event of a punctured diaphragm. See Section VI -

PIPING for proper venting procedures. Never connect

the regulator to the diaphragm valve vent.

When the regulator is to be installed or replaced, take

care not to distort the body casting. Apply wrench only to

the heavy body section adjacent to the pipe thread.

XII

MAIN AUTOMATIC VALVES

NOTE: All burners are equipped with dual valves.

Select the type you have and reference. Burner

construction for special codes and/or insurance

requirements such as Factory Mutual or Industrial Risk

Insurers may require alternate construction. (Refer to

Section XIV SPECIAL EQUIPMENT).

1.

Diaphragm Main Automatic Valve

(Employed with Redundant Solenoid Valve.)

The Honeywell V88 diaphragm valve supplied on a

UNIPOWER burners is of the slow opening, fast closing

type and requires venting to the bleed connection on the

burner box. Closing force combines a gas pressure

differential, diaphragm weight and spring.

When the controller is not calling for heat, the coil is

de-energized. The plunger of the three way actuator is in

the down position, so that the bleed is closed and the

supply port is open. Gas flows to the top diaphragm,

causing the gas pressure and spring to hold the valve

closed.

With a call for heat, the flame safeguard energizes the

coil. This pulls the plunger to the up position, opening

the bleed valve and closing the supply port. The gas

then bleeds off the top of the diaphragm, allowing the

gas pressure below to lift the diaphragm and open the

valve. When all the gas has bled off the top of the

diaphragm, the valve is fully opened. In the event of a

power failure during operation, the valve will close.

Normal operation will resume upon restoration of power.

For general service, tests for gas tightness and proper

operation will suffice. If leakage is observed, replace

valve.

MODEL

G56B(P)

G57B(P)

G58B(P)

G69B(P)

AIR

ORIFICE

#26

(.147)

#30

(.128)

#26

(.147)

#26

(.147)

NATURAL

PILOT

ORIFICE

#60

(.040)

#60

(.040)

#55

(.052)

#55

(.052)

PROPANE

PILOT

ORIFICE

#64

(.036)

#64

(.036)

#56

(.046)

#56

(.046)

APPROX.

CAPACITY

BTU/HR

3500

3500

5000

5000

WIRE DRILL SIZES