3 gost-r mark, 4 gas group classification, 3 gost-r mark 12.4 gas group classification – Videotec EXPT User Manual

Page 20

EN - English - I

nstruc

tions manual

18

12.3 GOST-R Mark

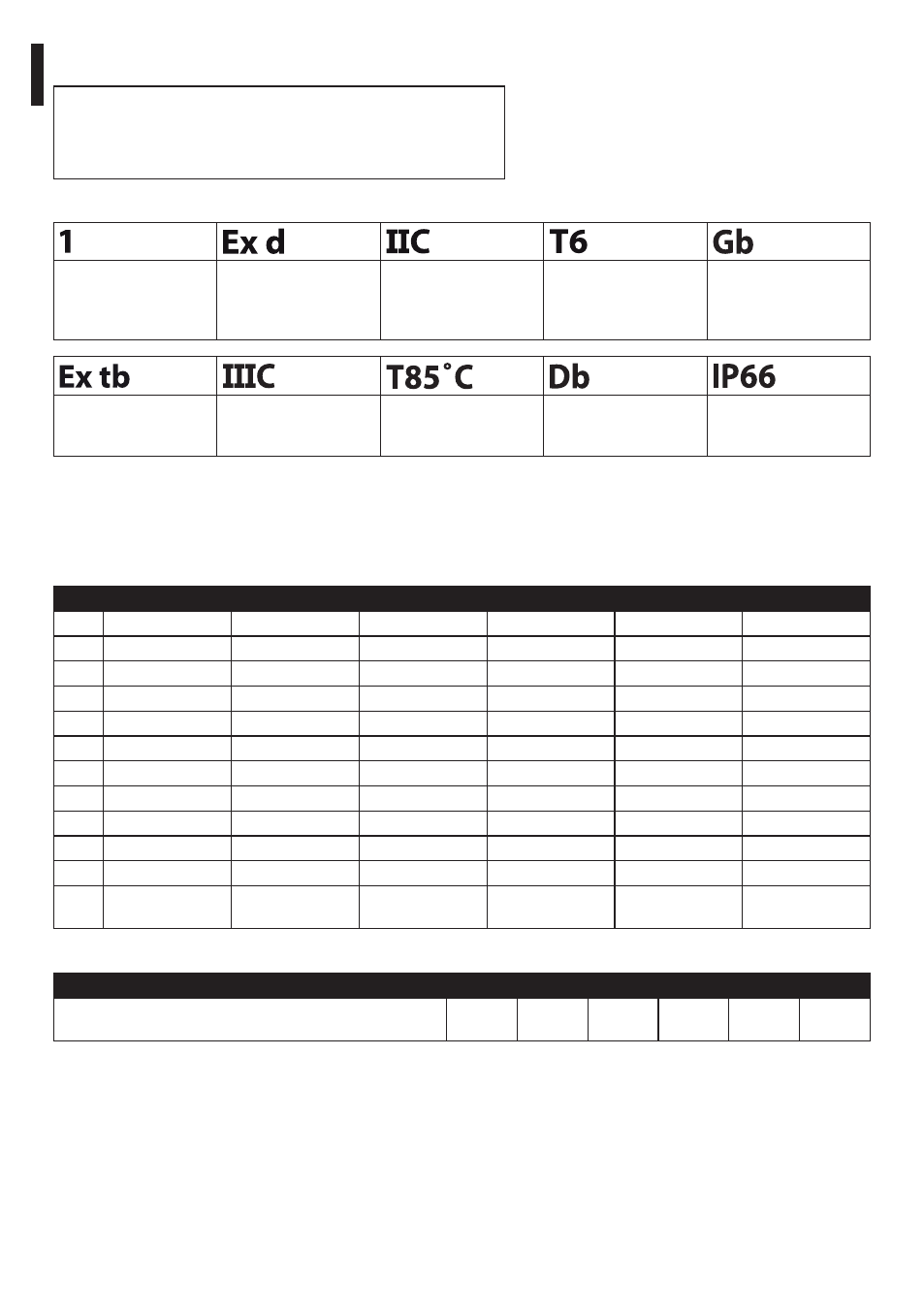

1 Ex d eeC T6 Gb

Ex tb eeeC T85˚C Db IP66

Fig. 12

Protection level

Explosion-proof

housing for

potentially explosive

environments

Gas group

Gas temperature

classification

Protection level of the

equipment for gas

Dust ignition

protection for zone

types 21-22

Dust group

Maximum surface

temperature for dusts

Protection level of the

equipment for dust

IP protection degree

Tab. 03

12.4 Gas group classification

The table below shows the classification of some gases and vapours, according to the explosion-proof

protection group and the temperature class. For a complete list see IEC/EN 60079-12 and IEC/EN 60079-20.

T1

T2

T3

T4

T5

T6

IIA

Acetone

N-Butane

Petrol

Acetaldehyde

Ethyl nitrate

Ethanol

N-Butyl

Diesel fuel

Ether

Ethyl acetate

Avgas

Ammonia

Heating oil

Pure benzene

N-Hexane

Acetic acid

Carbon monoxide

Methanol

Propane

Toluene

IIB

Ethylene

IIC

Hydrogen

Acetylene

Carbon

disulphide

Tab. 04 The above temperature classes automatically cover the lower classes (T6 is better than T1).

Class IIB also covers class IIA. Class IIC also covers classes IIB and IIA.

TEMPERATURE CLASS

T1

T2

T3

T4

T5

T6

Maximum allowed surface temperature (°C) for the

housing* in the corresponding class

450

300

200

135

100

85

Tab. 05 * Normally refers to the maximum ambient temperature of the installation. The lower the ignition temperature of the related

explosive atmosphere, the higher should be the maximum allowed surface temperature of the housing.

The maximum surface temperature is determined for a 5mm-thick layer of powder and the installation

regulations require a margin of 75K between the surface temperature and the ignition temperature of the

powder under consideration.