2 installation, 1 installing the camera, 2 installing the pan & tilt – Videotec EXPT User Manual

Page 12: 3 connecting the pan & tilt

EN - English - I

nstruc

tions manual

10

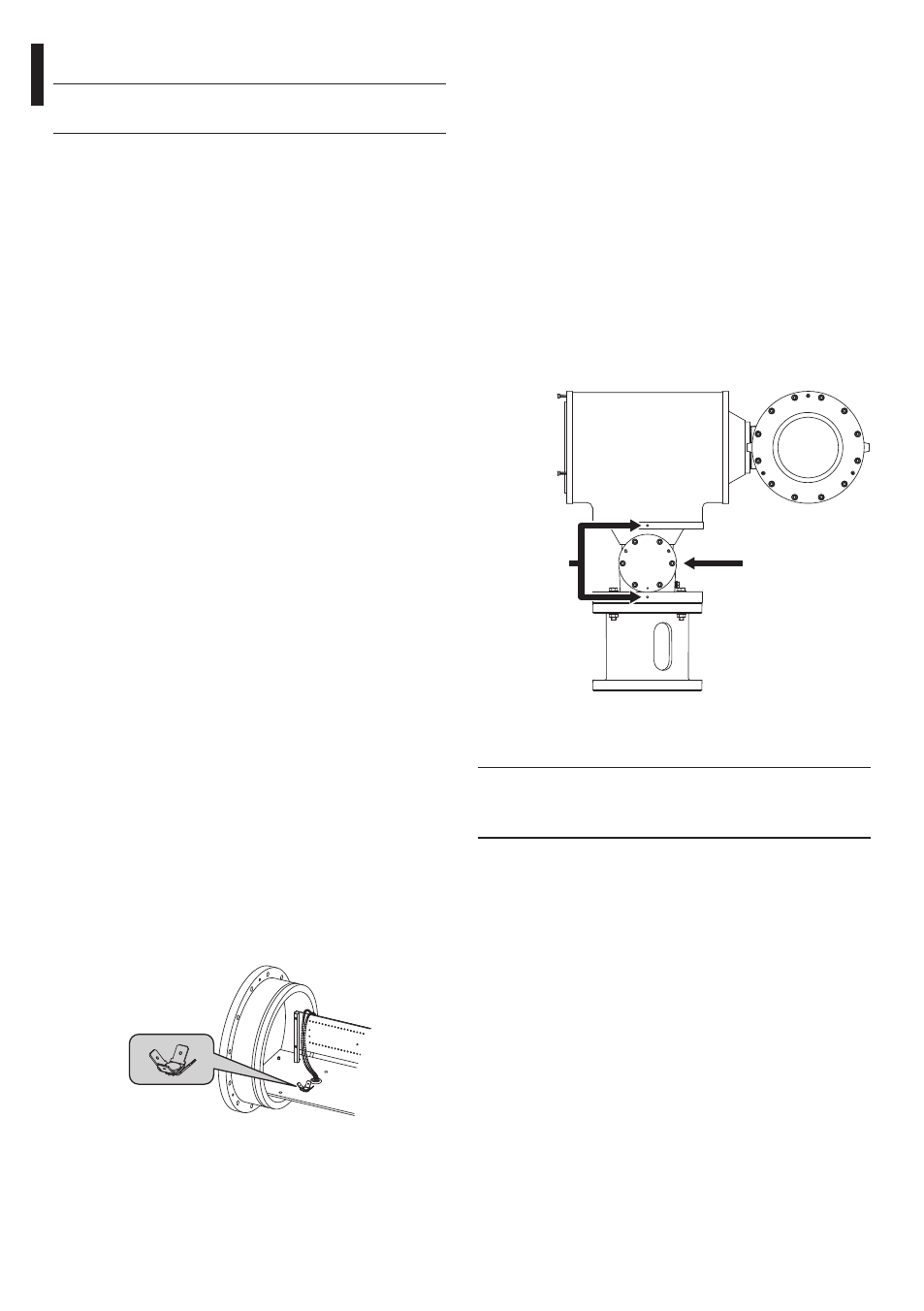

6.2.2 Installing the pan & tilt

For a wall-mounted P&T, the special bracket is used:

this is attached using the 4 holes, diameter 11mm.

For a parapet mounting, on the other hand, it is

possible to make use of the supporting disc on the

base, which has 4 holes, 8.5mm diameter, at 90°

intervals.

As regards this, to make sure the P&T is able to move

through its whole range, the bottom flange of the

central body and the support disc on the base have

two red vertically aligned marks.

When the P&T has been installed, these marks should

face the installer, because they represent the point

of reference for horizontal movement over the whole

range of ±180° with respect to the installation point.

Flange

(other side)

Marks

Fig. 04

6.2.3 Connecting the pan & tilt

h

Before proceeding with the following

operations, make sure that the P&T control

unit voltage is correct.

To connect the pan & tilt to the control unit, use the

supplied multipolar cable. Refer to the electrical

diagram attached to this handbook and carry out the

following operations:

• Disconnect the control unit from the power supply;

• Make the connections with the P&T (motors,

camera, lens etc.);

• Power the unit;

• Carry out the operational tests.

6.2 Installation

h

The installer must not use devices that

generate dangerous radiation.

One of the most important features of the EXPT

series P&T is the complete absence of rotation cables,

whether for controlling the P&T or for controlling the

camera. This means that installation and maintenance

of the P&T are simple.

The multipolar cable supplied is already connected

and leaves the base via the Ex d 3/4" NPT IP66

armoured barrier cable gland.

The two flanges on the housing and the three flanges

on the central body each have 12 screws, while the

two flanges on the base each have 6 screws. All the

screws have a hexagonal head and a M6 thread. In

addition, each flange has 3 screws at 120° intervals to

facilitate extraction of the flange itself. When the M6-

thread screws have been unscrewed from the flange,

turning the 3 screws at 120° intervals (one turn per

screw at a time, in turn) will make it easier to extract

the flange.

6.2.1 Installing the camera

To install the camera, you have to extract the flange

closing the housing, which also supports the plate to

which the camera will be attached, and the related

terminal board. This plate is supported on two guides

attached to the housing; when the flange is removed,

the plate slides along the guides, so that it is easy to

fit and connect the camera and its accessories. During

installation, we strongly recommend insulating the

camera from the support plate using the supplied

insulating spacers.

Before closing the flange, after installing the

camera, make sure that the 4 earth wires have been

connected (back cover, front cover, housing body,

terminal board) and make sure they have been

placed at the same potential.

We recommend a torque wrench setting of 12.5Nm

for the 12 screws closing the flange.

Fig. 03