4 adjusting the limit switches (autopan version), 5 how use the p&t, 6 changing the back cover gasket – Videotec EXPT User Manual

Page 13

EN - English - I

nstruc

tions manual

11

6.2.5 How use the P&T

Remote control of the pan & tilt can be achieved in

the following ways:

• Manual - By directly piloting the motors via a

control console, with immediate start, stop and

reverse on both a horizontal plane (max 360°) and

a vertical plane (max -90°/+90°); there are two

mechanical limit stops at the ends of the maximum

allowed rotation range, to prevent further rotation

if the electronic limit switches (microswitches) do

not work.

• Autopan - Only for rotation on a horizontal plane,

over a cyclical range in both directions, for a

maximum angle of 270°. The limits are set by the

two potentiometers (RV1 and RV2) situated on the

PCB inside the base (autopan option).

• Automatic to preset points - Using the two

potentiometers (P1 and P2) situated on the axes of

rotation and mechanically connected to horizontal

and vertical movements; with this operating mode

it is possible to store the angular position of the P

&T using special external control circuits (preset

option).

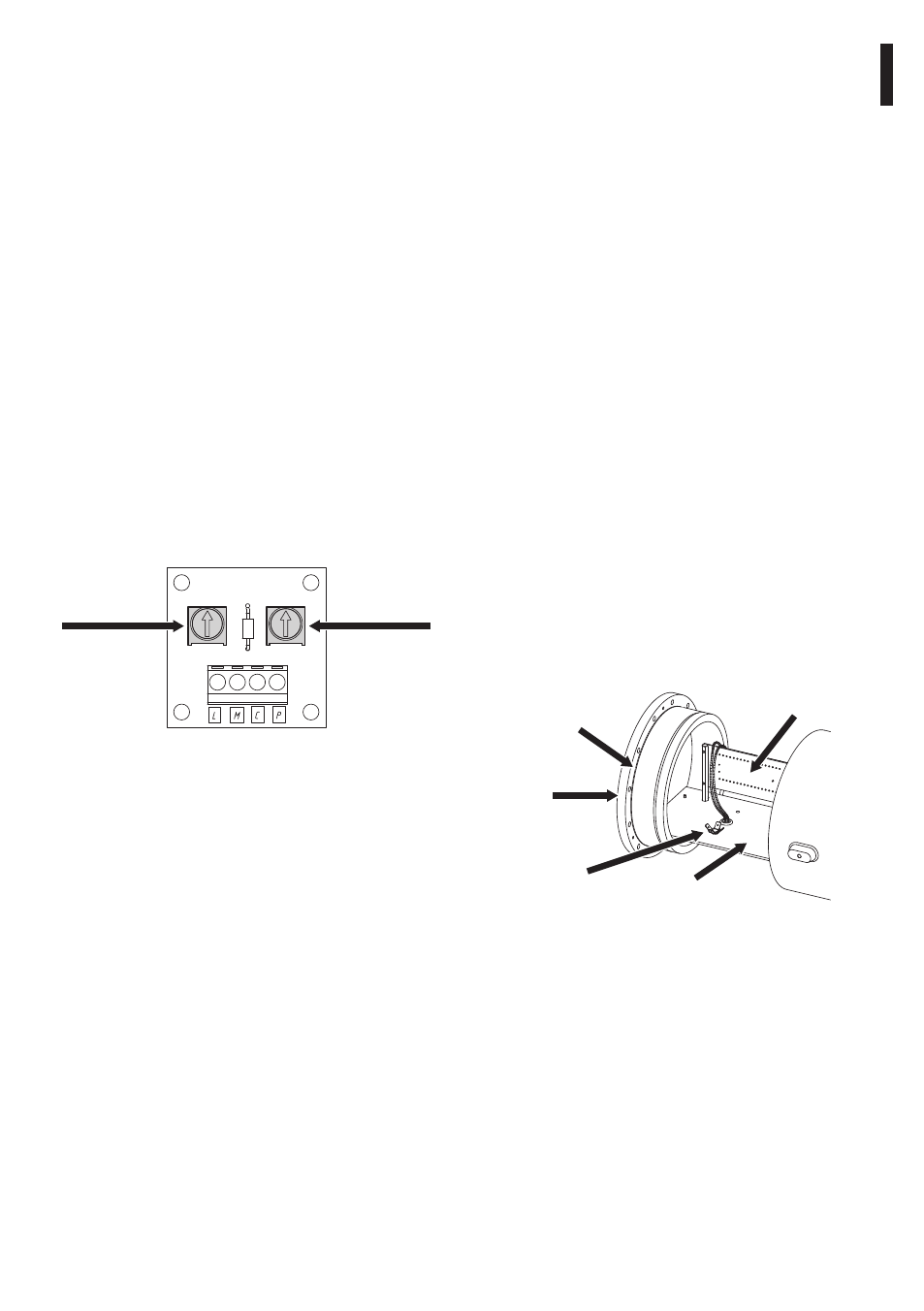

6.2.6 Changing the back cover gasket

If the back cover gasket of the housing is worn it

should be replaced using the supplied spare or,

failing that, using only and exclusively a VIDEOTEC

original part.

Flange

Earth

connection

Fixing plate

Back cover

gasket

Terminal board

Fig. 06

When changing the gasket, take care to make sure it

is properly inserted in its seating.

Reconnect the earth wires that had been

disconnected in order to extract the flange.

Close the flange properly, using a torque wrench

setting of 12.5Nm when tightening the 12 screws.

6.2.4 Adjusting the limit switches

(Autopan version)

To adjust the potentiometers for the electronic limit

switches controlling automatic cyclical panning,

take out the base flange that is opposite to the

flange with the red mark. The PCB containing the

two potentiometers, RV1 and RV2, is attached to

this flange.Take out the flange and keep it facing the

installer. The RV1 potentiometer (horizontal angle)

will be on the right, and is used to regulate the size

of the required angle during automatic horizontal

rotation. Potentiometer RV2, on the left (autopan

position) is used to position the angle fixed with

potentiometer RV1, in the required area over the

whole 360° range, by turning the knob clockwise or

anti-clockwise until the desired position is reached.

As regards potentiometer RV1, when it is turned anti-

clockwise as far as it will go, the minimum angle will

be obtained (30°), while turning it clockwise as far as

it will go will obtain the maximum angle (270°).

Intermediate values can be obtained by turning the

knob partially in either direction until the desired

angle is reached.

RV2

Autopan

position

RV1

Pan

angle

Fig. 05

Trimmer diagram.

To reach the connections (made by soldered joins)

of the multipolar input cable, it is necessary to

extract the base flange corresponding to the mark.

Two wires spiral out from the joins, one of which

terminates on the PCB terminal board situated in

the central body, while the other terminates on the

camera control terminal board inside the housing.

Since the input cable is already connected when the

device is supplied (as explained earlier), access to

these connections is unnecessary during installation

of the P&T, but access has been made possible for

maintenance purposes.