Outrigger pack, Hepa filter – Burr King BK75 User Manual

Page 17

Donaldson Company, Inc.

16

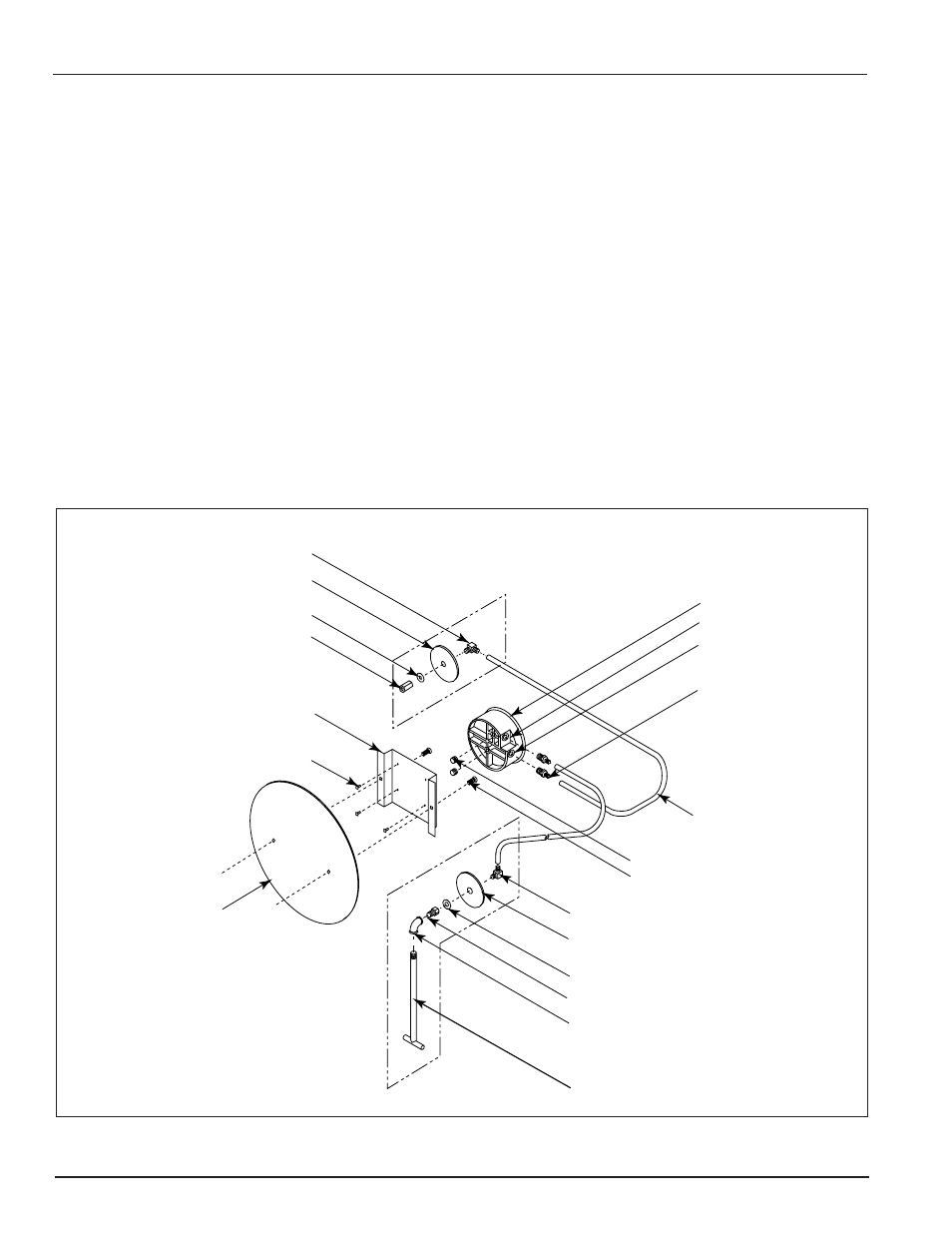

Magnehelic Gauge

The Magnehelic is a differential pressure gauge

used to measure the pressure difference between

the clean- and dirty-air chambers and provides a

visual display of filter change requirements. The

high-pressure tap is located in the dirty-air

chamber and the low-pressure tap is located in the

clean-air chamber.

1. Choose a convenient, accessible location on or

near the unit for mounting that provides the

best visual advantage.

If unit is equipped with factory-installed pressure

taps, skip to Step 5.

2. Before drilling, place a piece of non-combustible

cloth over the filter opening in the clean-air

chamber to protect them from drilling chips.

3. Place a piece of wood behind the drill location

in the dirty-air chamber to protect the filters

from damage by the drill bit. Use a .406-inch

diameter bit to drill the holes as shown in

Magnehelic Gauge, Detail A.

4. Mount the pressure tap hardware on the clean-

air chamber panel. Mount the pressure tap with

the tee inside the dirty-air chamber.

5. Plug the pressure ports on the back of the gauge

using two, 1/8-in NPT pipe plugs supplied.

Install two, 1/8-in NPT male adapters supplied

with the gauge into the high- and low-pressure

ports on the side of the gauge. Attach the

mounting bracket using three, #6-32 x 1/4-in

screws supplied.

1/8-in NPT x 90°

male elbow

clean-air chamber

drill location, see detail A

3/8-in flat washer

1/8-in NPT coupling

mounting bracket

#6-32 x 1/4-in mounting screws

support structure

mounting surface

Magnehelic gauge

high-pressure port

low-pressure port

two, 1/8-in NPT

adapters

plastic tubing

two, 1/8-in NPT pipe plugs

two, self-drilling screws

1/8-in NPT x 90° male elbow

dirty-air chamber

drill location, see detail A

3/8-in flat washer

1/8-in NPT adapter

1/8-in NPT x 90° elbow

static pressure tee

Magnehelic Gauge Assembly