Ductwork, Ductwork suction tube assembly, Magnehelic gauge – Burr King BK75 User Manual

Page 15

Donaldson Company, Inc.

14

Ductwork

Note: If unit is operated with more than the

maximum permissible inlet size, the fan

motor can overload or dust can settle in the

duct due to low air velocity.

1. Inlet collars can be located on the side, top, or

back of the cabinet by removing the desired

inlet cover plate and installing the inlet collar

using the same screws.

2. Use the shortest possible inlet duct. Avoid the

use of tees or flexible, wire-molded duct except

where machine motion or vibration needs to be

isolated. Flexible duct has a high static pressure

and reduces airflow.

3. Size duct for the recommended air velocity of

the conveyed material or material may collect

inside the duct.

4. Connect joints with sheet metal screws, rivets,

or sealer. Finish each joint with sealer or duct

tape.

Note: Sheet metal screws may cause fibrous or

stringing particulate to accumulate inside

duct. Use rivets or sealant in these

conditions.

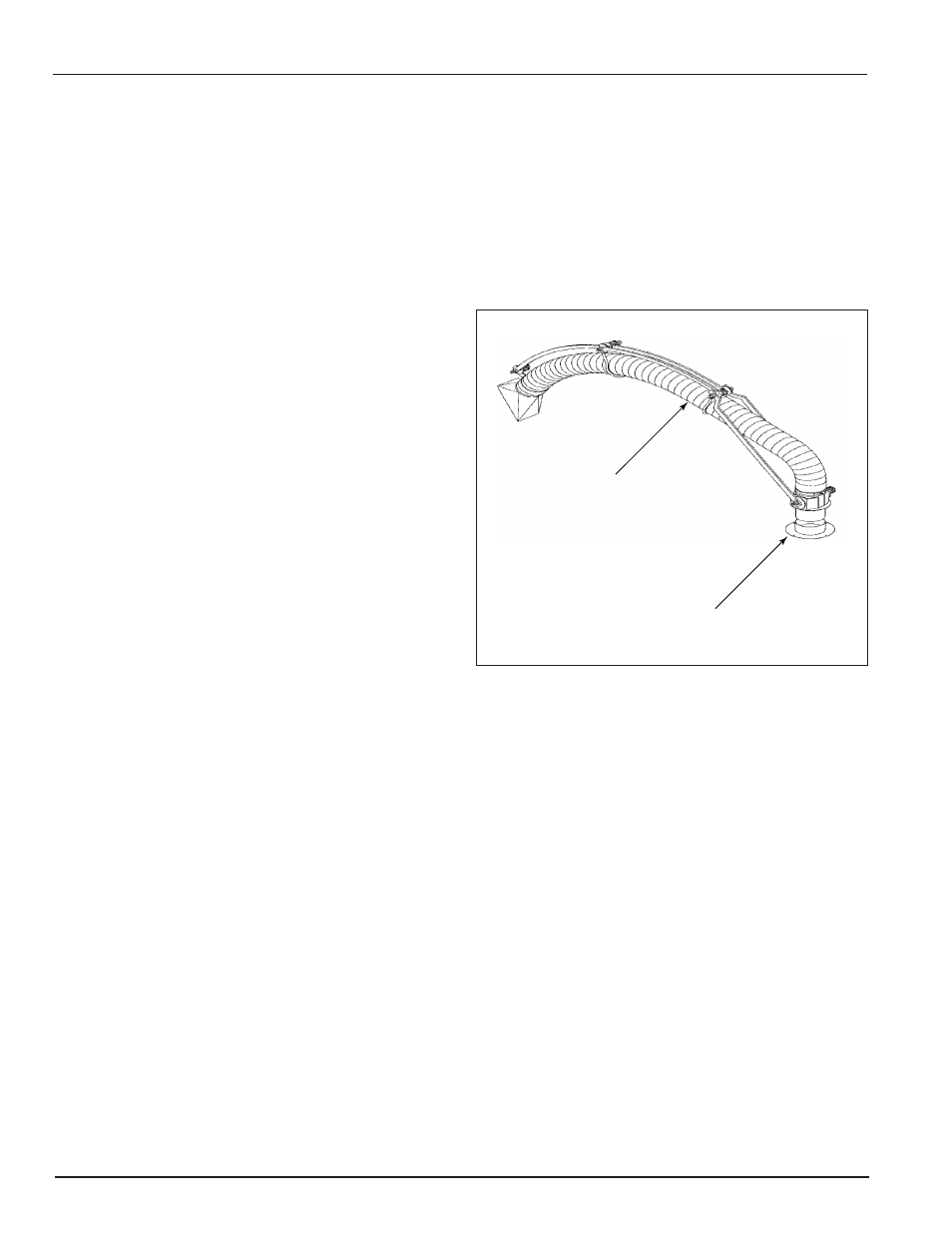

Suction Tube Assembly

3- and 4-Inch

1. Apply a thin layer of grease to the inside

surface of the inlet collar.

2. Slide the suction tube base into the inside of the

inlet collar. Swivel the suction tube to lubricate

all surfaces.

3- and 4-Inch Suction Tube Assembly

3 or 4-in

suction tube

assembly

inlet collar assembly

3 or 4-in