Sar 331 sa gds, Reference to accident - prevention regulations – Dake Model SAR 331 User Manual

Page 4

4

SAR 331 SA GDS

This machine has been built to comply with the national and community accident-prevention regulations in force. Improper use

and/or tampering with the safety devices will relieve the manufacturer of all responsibility.

1.1 - Advice for the operator

- Check that the voltage indicated on the plate, normally fixed to the machine motor, is the same as the line voltage.

- Check the efficiency of your electric supply and earthing system; connect the power cable of the machine to the socket and the earth

lead yellow-green in colour) to the earthing system.

- When the saw frame is in suspend mode (up) the toothed blade must not move.

- Only the blade section used for cutting must be kept unprotected. Remove guarding by operating on the adjustable head.

- It is forbidden to work on the machine without its shields (these are all blue or grey in colour).

- Do not use any artful system or device (for ex. shim) to prevent the vice from locking the workpiece. Do not hold the workpiece with

your hand during the cutting process.

- Do not charge the workpiece from the right to the left-hand side with respect of the machine front.

- Always disconnect the machine from the power socket before blade change or carrying out any maintenance job, even in the case

of abnormal machine operation.

- Always wear suitable eye protection.

- Never put your hands or arms into the cutting area while the machine is operating.

- Do not wear loose clothing with sleeves that are too long, gloves that are too big, bracelets, chains or any other object that could get

caught in the machine during operation; tie back long hair.

- Keep the area free of equipment, tools or any other object.

- Perform only one operation at a time and never have several objects in your hands at the same time. Keep your hands as clean as

possible.

- All internal and/or internal operations, maintenance or repairs, must be performed in a well-lit area or where there is sufficient light

from extra sources so as to avoid the risk of even slight accidents.

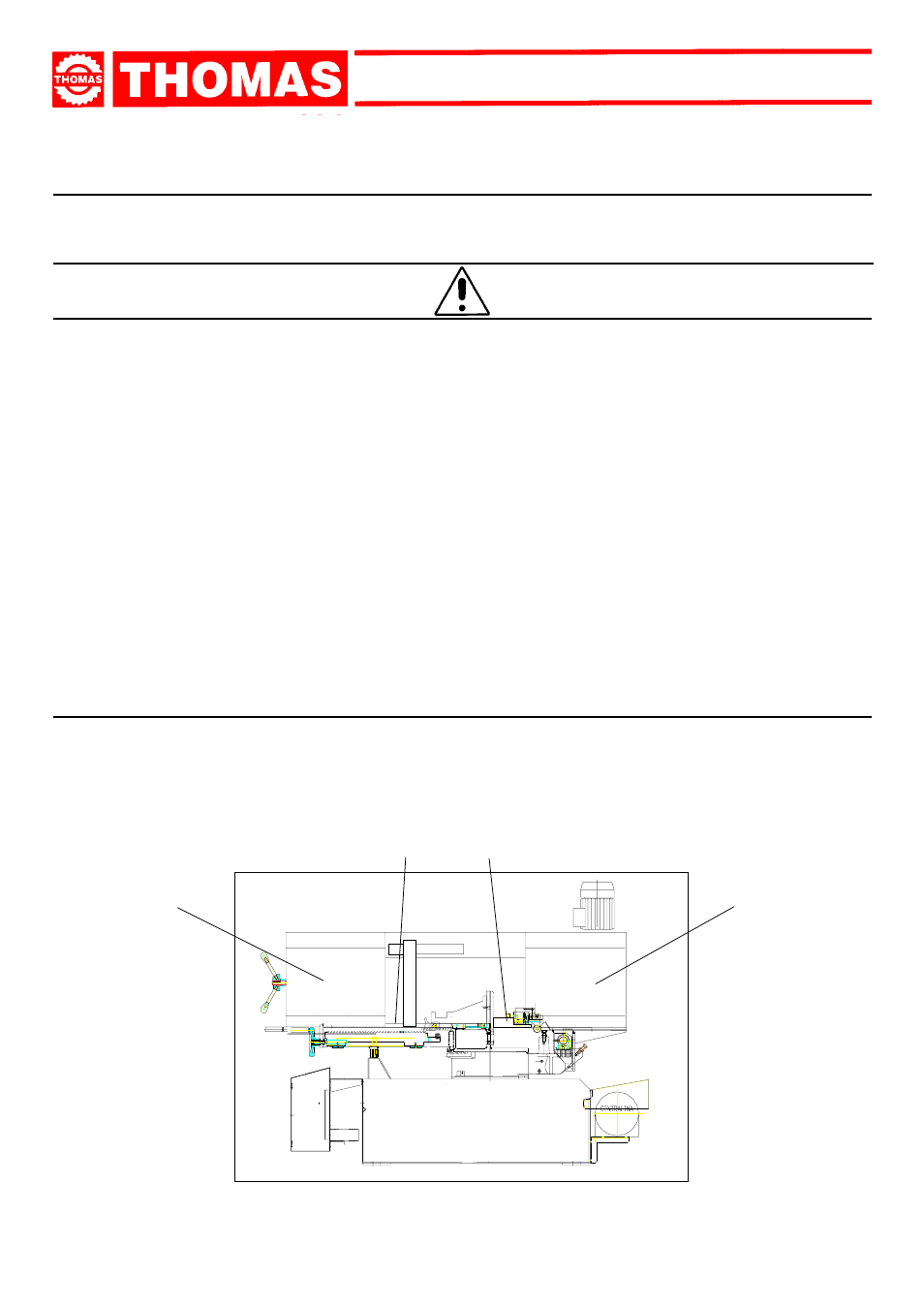

1.2 - Location of shields against accidental contact with the tool

- Blue or grey metal shield fixed frontally with screws to the fixed blade-guiding block (Ref. A).

- Blue or grey shield fixed with screws to the adjustable blade-guiding block. Guarantees that the section of blade which exceeds the

piece to be cut is covered (Ref. B).

- Grey metal casing fixed with hooks to the frame. Protects the flywheels from blade dragging (Ref. C).

1

REFERENCE TO ACCIDENT - PREVENTION REGULATIONS

A

B

C

C