Sar 331 sa gds, Regulating the machine – Dake Model SAR 331 User Manual

Page 10

10

SAR 331 SA GDS

REGULATING

THE MACHINE

7.1 - Blade tension assembly

7

The ideal blade tension is obtained by turning the belt-tighten-

ing handwheel until the relative microswitch activates (B).

The position of the microswitch is established by an instru-

ment that measures the blade stretch. This regulation must not

be modified.

NB: it is advisable to loosen the blade tension when the saw is not

being used.

It is advisable to always use blades having the dimensions declared

in this manual.

B

7.3 - Vice

- The vice can be made to move rapidly towards the piece to be

cut by keeping the hand lever (C) raised and moving the vice

manually. Before using the handwheel to lock the material to

be cut, make sure that the hand lever is interlocked with the

rack.

- The vice group can be positioned to the right or left of the

blade. If positioning is not fully completed, the sawing ma-

chine can be permanently damaged by the lowering move-

ment of the frame.

- Always keep the vice guide and relative thread clean and

oiled.

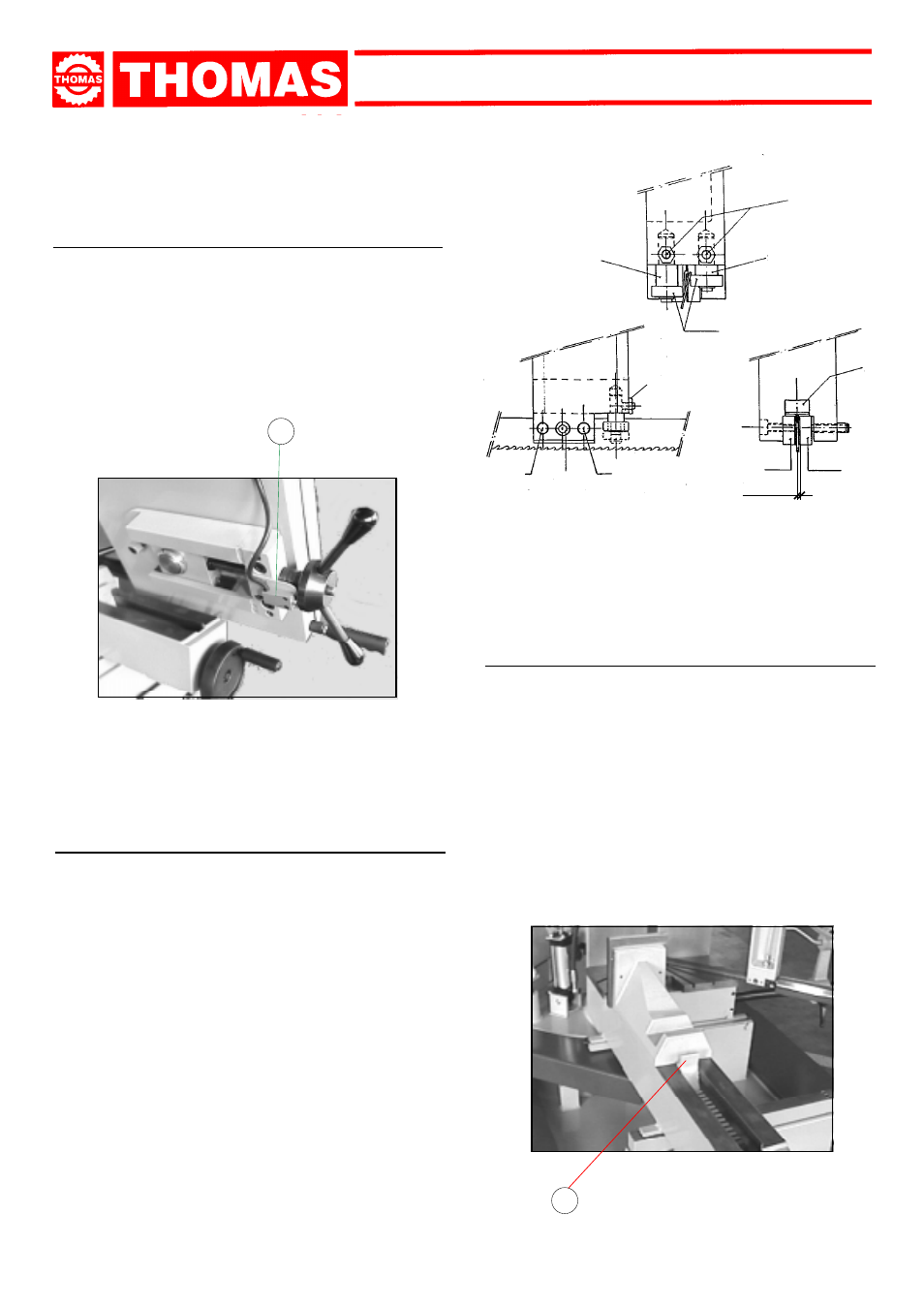

7.2 - Blade-guiding arms and plates

The blade is guided by plates that are regulated during the

testing phase according to the thickness of the blade. The mini-

mum clearance indicated in the figures should be maintained.

When the blade is to be replaced, make sure to always fit belts

with a 0.9 mm thickness because the blade-guiding plates have

been regulated for this thickness. If using toothed belts with

different thicknesses a new regulation must be carried out as

follows:

- Loosen the screw (1) and unscrew the grub screws (2), wid-

ening the space between the plates.

- Loosen the nuts (3) and the grub screws (4) and rotate the

pins (5 - 6) to widen the space between the bearings (7).

- Insert the new blade, then place the plate (8) against it. Tighten

the grub screws (2), leaving a 0.04 mm clearance to ensure

that the toothed belt slides well. After this, tighten the relative

nuts and the screw (1).

- Rotate the pins (5 - 6) until the bearings lean against the

blade, as indicated in the figure. Lock the grub screws (4) and

the nuts (3).

1

2

2

4

5

6

7

8

C

3

0,04