Section 4 - maintenance, Maintenance safety, First day & week of operation – Summers Disk-Chisel User Manual

Page 79: Maintenance safety -1

4-1

SECTION 4 – MAINTENANCE

MAINTENANCE SAFETY

1. STOP engine, place all controls in neutral, set parking brake, remove ignition key and

wait for all moving parts to stop before servicing, adjusting or maintaining.

2. BE CAREFUL when working around high pressure hydraulic system.

3. ALWAYS make sure that pressure is relieved from hydraulic circuits before servicing or

disconnecting from tractor.

4. USE EXTREME CARE when making adjustments.

5. KEEP CHILDREN AWAY from machinery at all times.

6. NEVER ALLOW anyone to walk or work under a raised piece of equipment without

installing cylinder and transport locks.

MAINTENANCE FOR AFTER THE FIRST DAY AND WEEK OF OPERATION

1. Grease lift arms, walking tandem assemblies, and hitch pivot. (There are a total of 12

daily grease zerks).

2. Check all hydraulic components for leaks daily.

3. Check tightness of all wheel bolts daily.

4. Check tightness of wheel bearings (See Page 6-21).

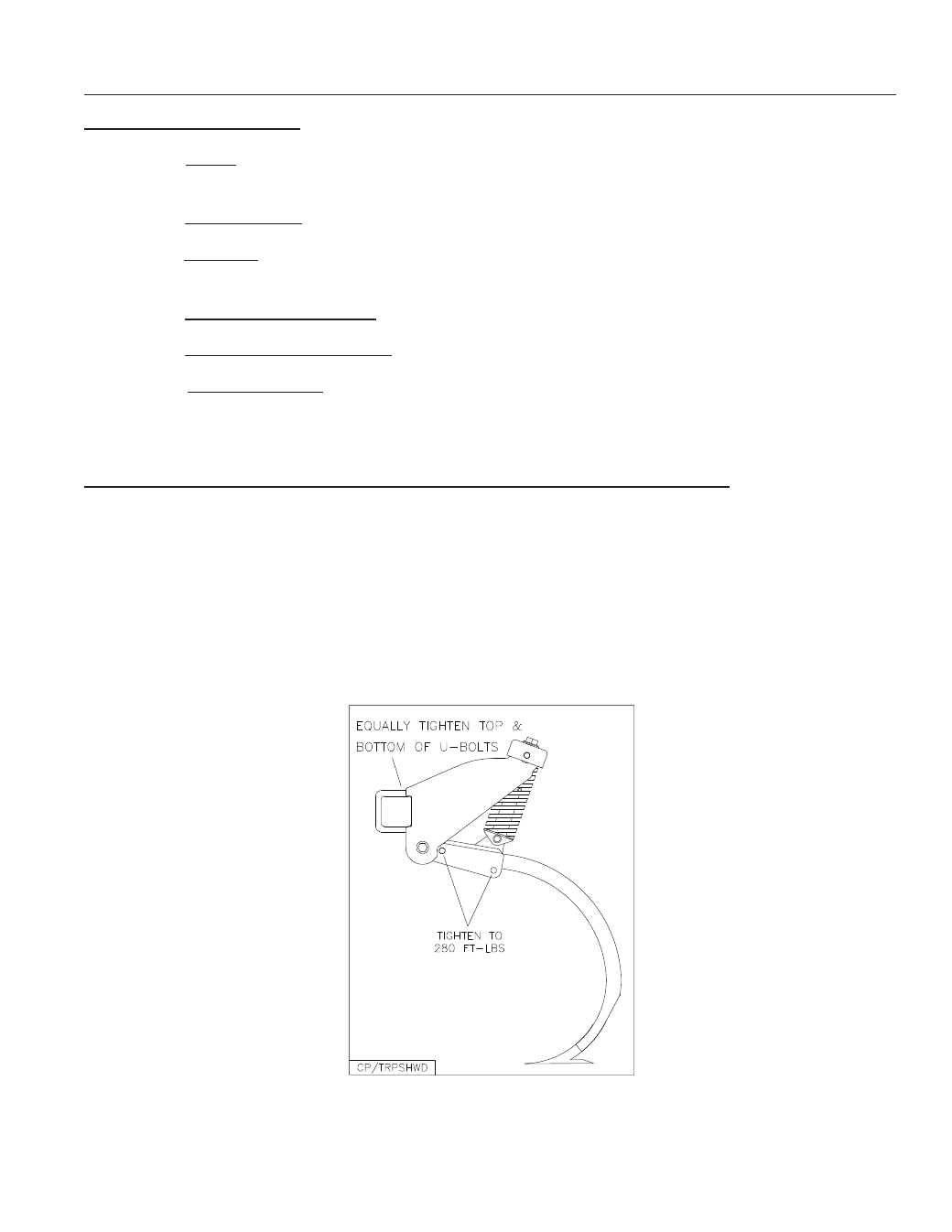

5. Check tightness of the following bolts on the trip assemblies.

6. Check tightness of all hardware. Pay special attention to the hitch bolts and all pivot

retaining bolts.