Pv200 controller, Operating specifications, Pv200 – High Country Tek ProValve 200 Series User Manual

Page 5: Closed loop proportional valve controller

021-PV200 Rev A

PV200 Uses Manual

5

Copyright © High Country Tek, Inc.

– 2013

PV200

Closed Loop Proportional Valve Controller

PV200 Controller

The ProValve200 controller drives proportional solenoid valves in a closed loop system. When the feedback is

greater than the command, coil A receives current; when the feedback is less than the command, coil B receives

current. The current is proportional to the difference between the command input and the feedback.

Once configured, the settings are permanently stored in the controller memory.

PV200 Features

Easily configured using HCT Graphical User Interface (GUI) or HCT Hand Held Interface (HHI)

LED indication of power, output current and fault status

DIN-rail mount housing with removable terminal blocks

Single mode for dual coil closed-loop position control

All input and output limits are independently adjustable

Adjustable output with short circuit protection

Fully adjustable PID control loop

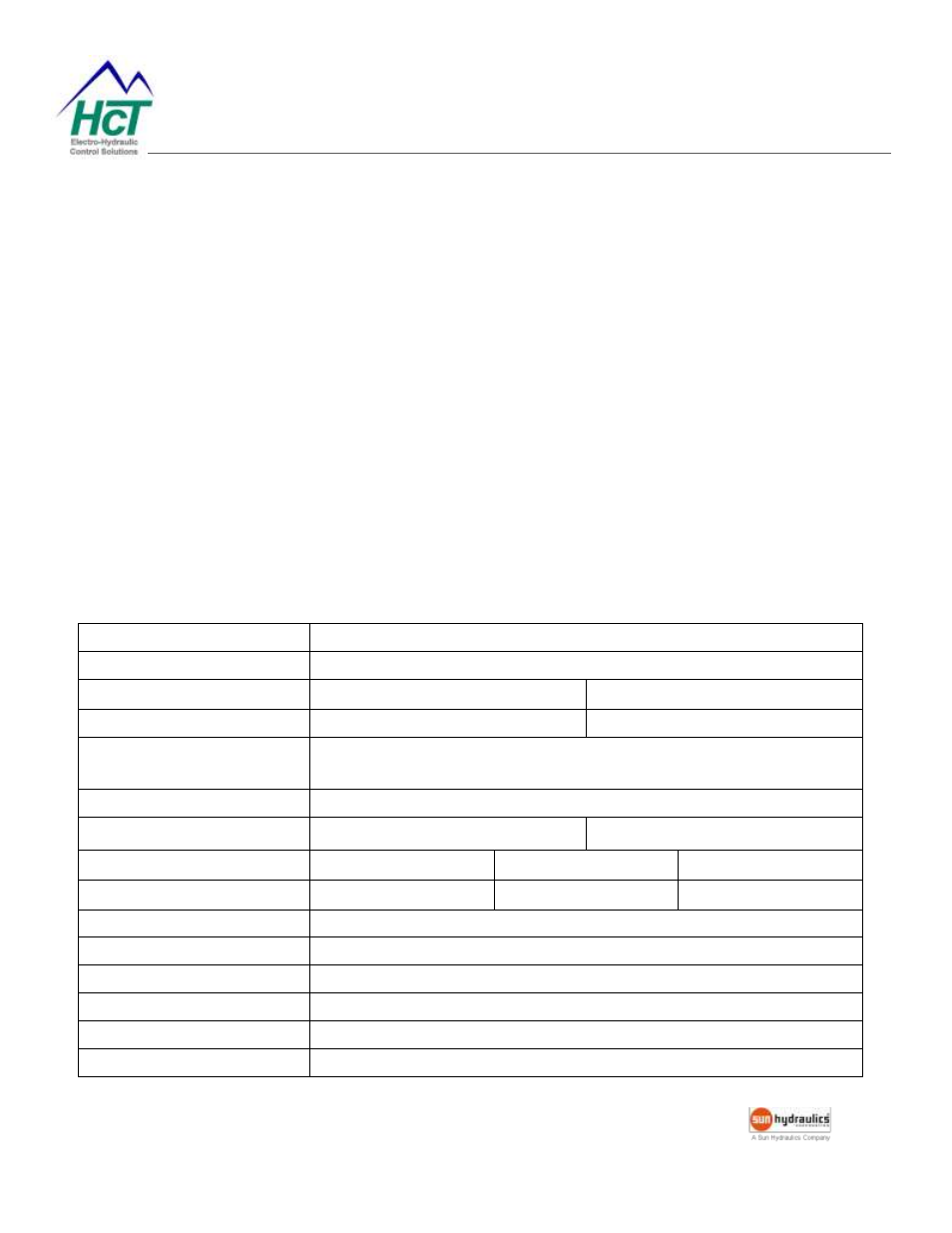

Operating Specifications

Supply Voltage

12 to 30VDC

Supply Current

Valve current + 50mA (Quiescent Max)

Output Current

Standard: 2.5A max

-L: 500mA MAX

Coil Resistance

Standard: 2Ω MIN

-L

: 10Ω MIN

Dither Frequency

35, 41, 49, 61, 81, 122, 244Hz

(Select OFF for PWM frequency 15.63KHz)

Analog Input Range

[0, 10]V, [0, 5]V, [0, 20]mA

Analog Input Impedance

> 100K

for voltage input

500

for current input.

Digital Input Range

-24: 12 to 30VDC

-115: 100 to 130VAC

-230: 210 to 250VAC

Digital Input Impedance

-24: 3.3k

-115: 33k

-230: 75

Process Linearity

±0.1% of full input range

Process Repeatability

±0.2% of full input range

Process Control

PID control Loop, 10ms loop time

Operating Temperature Range

0º to 70º C (operating); -40º to 85º C (storage)

Enclosure

Compact

Dimensions

Inch: 3.9 L x 4.5 W x 0.4 H, Mm: 99 L x 114.5 W x 10 H