Installation instructions – AMETEK 1500 Induction Style Relay User Manual

Page 2

2

Installation Instructions

Relay: Install relay in level upright position. Connect wires

from AC supply to terminals #3 and #4 on relay. Make sure

power is of same rated voltage and frequency as shown

for connection to primary coil on relay data plate. Relays

draw 9 volt amperes.

Electrodes: Install electrodes in tank or well by

suspending them vertically from an electrode holder or

some other suspending means. One electrode should be

set at desired start level and one at desired stop level. For

sewage or surface drainage sumps, make sure electrodes

are hung far enough apart so that foreign matter fl oating

on water cannot foul electrodes. Size 18 or larger Type TW

or THW wire is recommended for connection to the relay.

CAUTION - Although the electrodes are connected

to a low energy secondary coil output which has

inherently low current, there may be up to 800 volts

between the electrodes or from an electrode to

ground. (See Secondary Coil Table.) Thus wiring and

electrodes should be installed to protect personnel

from accidental contact.

Ground: A system ground return circuit is required from the

indicated relay terminal to the liquid in order to complete

the secondary circuit of relay. Conduit should not be

used. Instead, connection should be made directly to

uninsulated metal tank, or to metal pipe connected to tank

below normal low liquid level. In wells, connect ground

to pump or metallic water pipe. For concrete, wood, or

insulated tanks, use an extra common electrode extending

slightly below the longest operating electrode.

Secondary Coil: Because the secondary voltage on all B/

W relays is an induced voltage generated within the relay

itself, the secondary coil should never be connected to any

source of power. Voltage of the secondary coil installed on

a given relay is determined by conductivity of liquid to be

controlled.

Load Connections: B/W relays are two-wire control

devices having load contacts rated at 1 hp., single-phase,

115 or 230 volts AC or standard duty pilot rating up to 600

volts AC. In operation, load contacts act as a switch to

open or close a circuit. Connecting them to an external

load does not introduce a source of alternating current into

the circuit.

Accordingly, in making connections for direct operation of

single-phase loads within rated capacity of relay, power

connections must be made as shown in relay wiring

diagram.

To operate higher rated single-phase loads or three-

phase loads, a magnetic starter must be used. In making

connections to motor starter, follow directions given on

the starter wiring diagram for connecting two-wire control

devices.

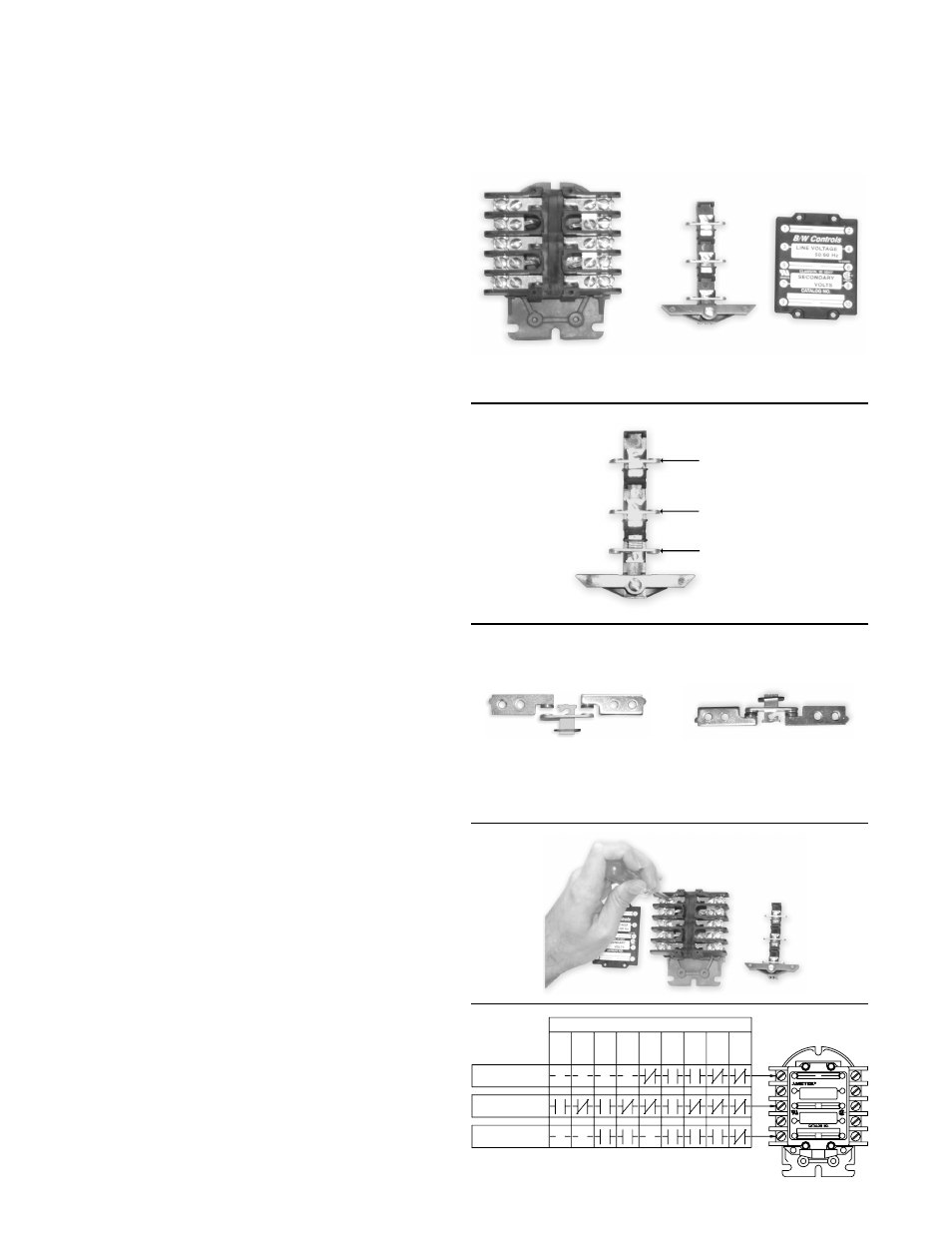

Field Replaceable and Convertible Contacts

The Series 1500 Induction Relay provides circuit versatility by offering

a contact kit that allows fi eld conversions from N.O. to N.C. or N.C.

to N.O. contact arrangements. This option also allows you to add or

replace contacts (up to 3 per relay) as required for expansion of your

liquid level control needs.

Remove cover plate and armature

N.O. Contact

N.C. Contact

For a N.O. contact, install the

stationary contacts facing toward

the bottom of the relay (toward the

armature).

For a N.C. contact, install the

stationary contacts facing in

toward the top of the relay (away

from the armature).

Contact Kit Part No. 15-000001

R

1

2

3

4

5

6

7

8

9

10

R

Clawson, Michigan 48017 U.S.A.

B/W CONTROLS

LINE VOLTAGE

50/60 Hz

SECONDARY

VOLTS

1500-

CONTACT ARRANGEMENT CODE

A B C D E F G H J

1 N.O.

1 N.C.

2 N.O.

1 N.O.

1 N.C.

2 N.C.

2 N.O.

1 N.C.

1 N.O.

2 N.C.

3 N.C.

3 N.O.

TOP CONTACT

TERMINALS 1 & 2

MIDDLE CONTACT

TERMINALS 5 & 6

BOTTOM CONTACT

TERMINALS 9 & 10

N.O.

N.O.

N.C.

For a N.O. contact,

install the moveable

contact in the

armature assembly

facing toward the top

of the relay. (away

from the armature)

For a N.C. contact,

install the moveable

contact in the

armature assembly

facing toward

the bottom of the

relay. (toward the

armature).