AMETEK 955S Smart Brik LDT User Manual

Page 3

3

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

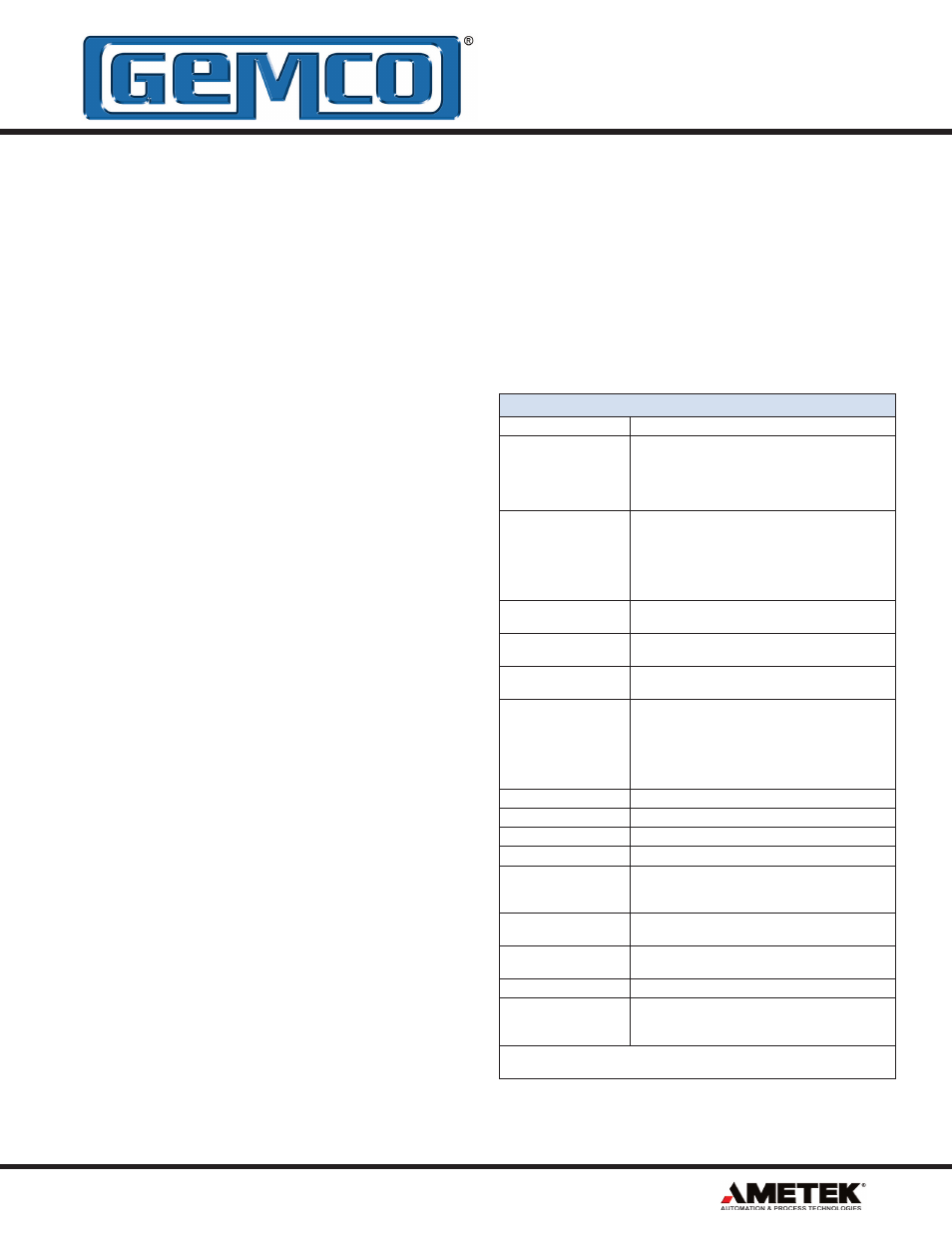

Specifications

Input Voltage

10 to 30 VDC

Current Draw

Voltage Units

Current Units

80mA @ 10 VDC

35mA @ 30 VDC

90mA @ 10 VDC

55mA @ 30 VDC

Output

0 to 10 VDC

10 to 0 VDC

-10 to 10 VDC

10 to -10 VDC

-5 to 5 VDC

5 to -5 VDC

0 to 5 VDC

5 to 0 VDC

4 to 20mA

20 to 4mA

Linearity

+/- 0.05% of Stroke or +/- 0.028” whichever is

greater

Accuracy

+/- 0.1% of Stroke or +/- 0.050” whichever is

greater

Repeatability

+/- 0.01% of Full Stroke or +/- 0.014” whichever

is greater

Update Time

Stroke Length:

4” ≤ 50”

51” ≥ 100”

101” ≥ 150”

151” ≥ 180”

1ms with 5ms settling time

2ms with 4ms settling time

3ms with 3ms settling time

4ms with 4ms settling time

Operating Temperature -20° to 70° C

Span Length

4” to 180”

Null Zone

3.00”

Dead Band

1.50”

LED

Green = Power is applied and magnet is present

Red = Fault, magnet is in the Dead Band or lost

Yellow = Out of the active programmed range

Connector

Standard 4 Pin Micro

12mm Euro Connector

Approvals

CE

FM - When installed per drawing E0241100

Enclosure

IP67, IP68 Optional

Output Load

Voltage Output

Current Output

1KΩ (1.5KΩ for +/- 10V) (minimum)

(Vin - 4) / 20mA (maximum)

Specifications are subject to change without notice.

Specifications are based on a typical 36” LDT.

NOTE 3: ZERO or SPAN can be adjusted individually

without setting the other.

NOTE 4: ZERO = 0V on 0 to 10 VDC units and 4mA on 4

to 20mA units.

For your convenience, Ametek offers an in-line

programming unit (955-1409) that can be installed in-

line with the LDT. The in-line programmer uses a rocker

switch to program the zero and span. For details, see

accessories on page 7.

Automatic Gain Control

The Automatic Gain Control feature is only used when

sensing a magnet other then the standard SD0521800

slide magnet. If you are using the standard slide magnet

skip to Setting Zero and Span Position.

When using the Floating Magnet assembly (SD0522100),

the magnet should be installed within 3/8” of the sensing

surface. The magnet assembly should also be installed

in such a manner that it remains an even distance from

the aluminum extrusion throughout the entire stroke.

Improperly installed magnets can result in output signal

non-linearity.

To set the Automatic Gain Control (AGC) level for the

probe follow these steps:

1. Place magnet assembly close to the Dead Band (but

within the active region) of the probe

2. Power down the probe

3. Short “PRGM” pin (pin 2) to ground (pin 3)

4. Apply power to probe

A. The LED flashes RED indicating it is in the AGC

mode.

B. The LED will change to flashing GREEN when it

has determined the proper AGC level and has

saved it to non-volatile memory.

NOTE: When the probe is in AGC mode, the output will

be at either 0 volts or 4mA, depending on the model that

was ordered.

The AGC is now complete.

To place the probe back into the normal operating mode

follow these steps:

1. Power down the probe

2. Remove short from “PRGM” pin

3. Apply power to the probe

The probe is now in the normal operating mode.

NOTE: The north pole of the magnet should be pointed

towards the probe.