AMETEK 955S Smart Brik LDT User Manual

Page 2

2

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

Mounting

The transducer can be mounted vertically or horizontally

using SD0522000 Mounting Brackets. The mounting

brackets slide in the grooves on the lower part of

the extrusion and clamp down when tightened. It is

recommended to use one mounting bracket on each end

and every three feet between.

NOTE: If using the floating magnet option, you must

set the automatic gain control.

Ferro-magnetic material, (material readily magnetized)

should be placed no closer than .25” from the sensing

surface of the LDT.

LED Colors

Green: Magnet is present and within the active

programmed range.

Red: Fault, the LDT has lost its signal from the magnet or

the magnet has moved into the Null Zone or Dead Band.

Yellow: Magnet is out of the programmed ZERO to SPAN

range.

Setting Zero & Span Positions

The Series 955S is programmable over the entire active

stroke length of the LDT. Keep in mind that there is a

3” Null area at the connector end of the LDT and a 1.5”

Dead area at the other end of the LDT that the magnet

must stay out of at all times. The diagnostic LED can

help aid you in the setup of the Zero and Span. A green

or yellow LED means that it is OK to program the LDT

in this area, a red LED means that the LDT cannot be

programmed in this area.

To set the ZERO and SPAN position for the probe follow

these steps:

1. Power up the probe in normal operating mode (i.e.

“PRGM” pin floating)

2. Place magnet assembly where ZERO is to be located,

but within the active region of probe

3. Momentarily short “PRGM” pin (pin 2) to ground (pin 3)

4. Place magnet assembly where SPAN is to be located,

but within the active region of the probe

5. Momentarily short “PRGM” pin (pin 2) to V+ (pin 1)

NOTE 1: AGC should be set first before setting the

ZERO and SPAN positions when using a floating magnet.

NOTE 2: SPAN could also be set first, followed by setting

the ZERO position.

Introduction

The 955S Smart Brik is an accurate programmable,

auto-tuning, non-contact, linear displacement transducer

in an economical, low profile package. The transducer

utilizes our field proven magnetostrictive technology

to give absolute position, repeatable to .01% of the

programmable sensing distance. The streamlined

anodized aluminum extrusion houses the sensing element

and electronics. The magnet moves over the sensing

element that determines the position and converts it to an

analog output. It can be ordered with various outputs:

0 to 10 VDC

-10 to 10 VDC

0 to 5 VDC

-5 to 5 VDC

4 to 20mA

The 955S Smart Brik has a few truly unique features. The

first one being the LDT’s auto-tuning capability, the ability

to sense a magnet other than the standard slide magnet

and adjust its signal strength accordingly. Another feature

is the analog output is programmable over the entire

active stroke length. The active stroke area of the LDT lies

between the Null Zone and Dead Band.

There is a diagnostic LED located at the connector end of

the probe that remains green while a good magnet signal

is present and when the magnet is in the programmed

stroke area. The LED turns yellow when the magnet is

out of the programmed active range, but still within the

active stroke area. The LED turns red and the output

goes to 0 volts on voltage output units, or 4mA on current

output units when there is no magnet present or when the

magnet is out of the sensing area. The unit can easily be

changed in the field.

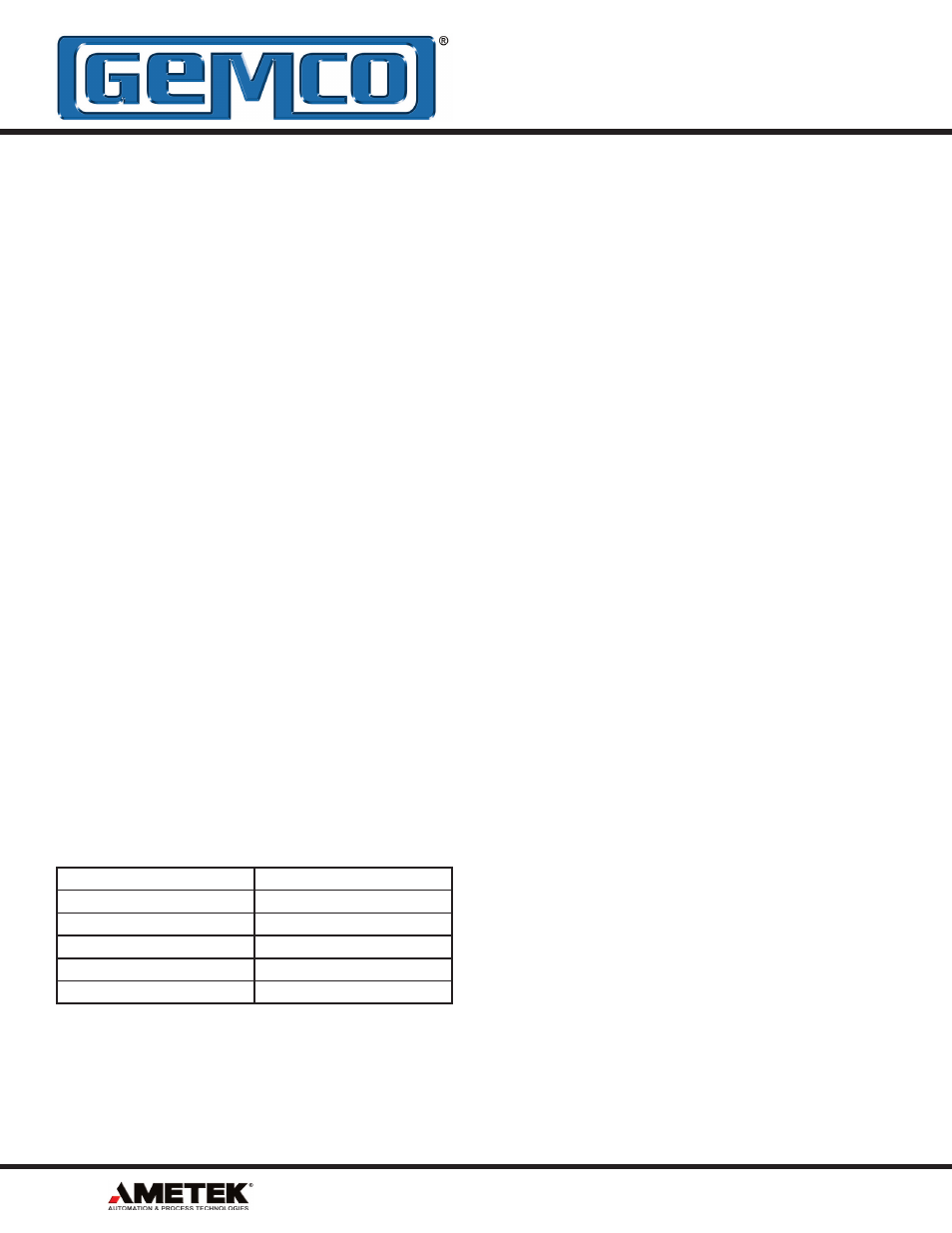

From

To

0 to 10 VDC

10 to 0 VDC

-10 to 10 VDC

10 to -10 VDC

0 to 5 VDC

5 to 0 VDC

-5 to 5 VDC

5 to -5 VDC

4 to 20mA

20 to 4mA

NOTE 1: As an added benefit, the 955S is FM approved

for Class I, Div II, Groups A, B, C, D applications when

installed and wired per drawing E0241100.

NOTE 2: If your application does not require FM Class I,

Div II approval, wire the 955S using a standard 4 pin Euro

cordset from Ametek or others.