0 troubleshooting, 0 troubleshooting table, 0 troubleshooting 11.0 troubleshooting table – ARI Armaturen DP34 EN User Manual

Page 27

0040504000 1210

Page 27

Operating and installation instructions

Pneumatic actuators - DP32 / DP33 / DP34

10.0 Troubleshooting

In the event of malfunction or faulty operating performance check that the installation and

adjustment work has been carried out and completed in accordance with these Operating

Instructions.

If malfunctions cannot be eliminate with the help of the following table „11.0

Troubleshooting table“, the supplier or manufacturer should be consulted.

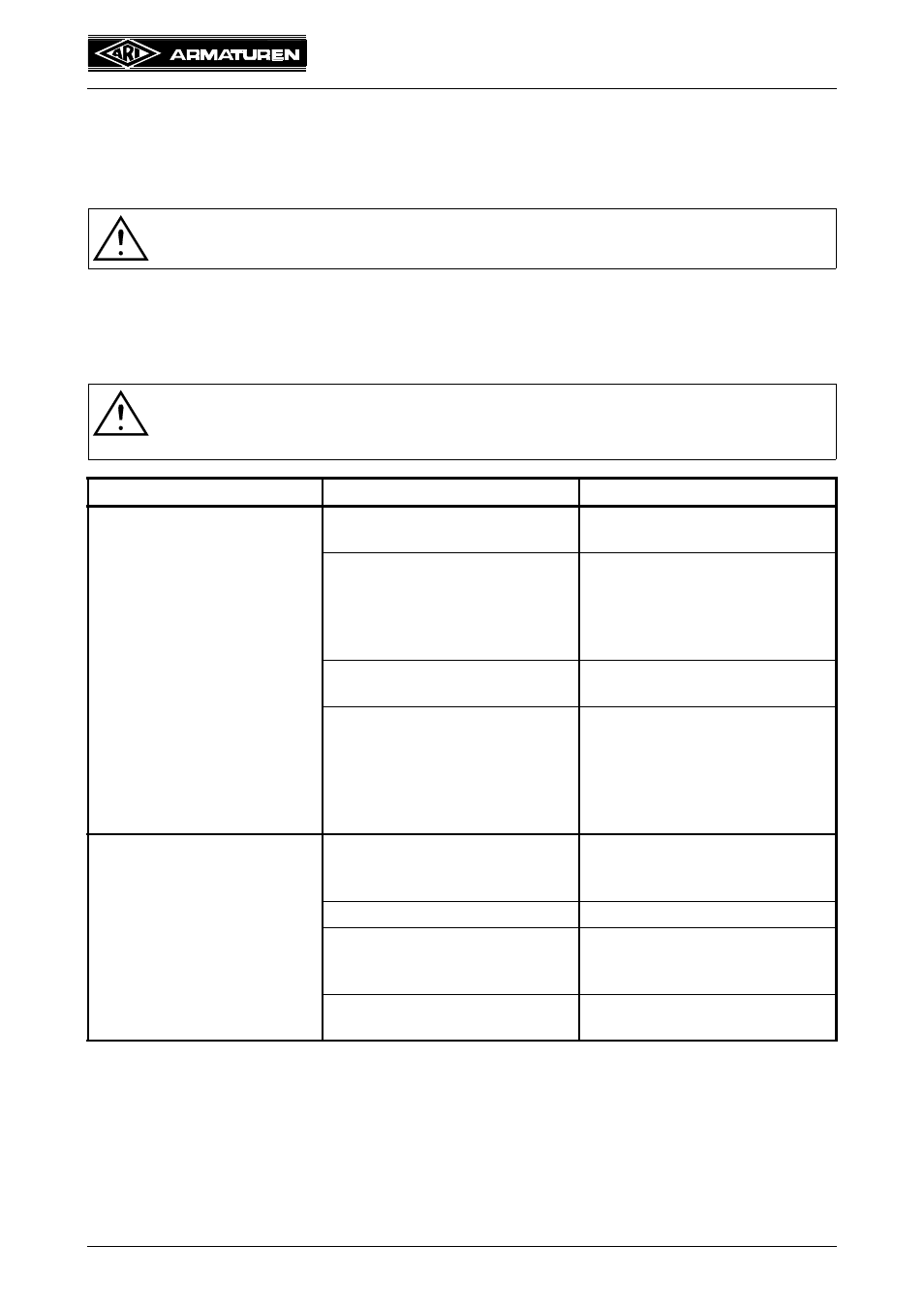

11.0 Troubleshooting table

ATTENTION !

It is essential that the safety regulations are observed when identifying faults.

ATTENTION !

- read point 7.0 and 8.0 prior to dismantling and repair work !

- read point 6.0 before restarting the plant !

Fault

Possible causes

Corrective measures

Actuator unit does not move No compressed air on the

control pressure line

Discern the causes and remedy

Actuator unit has been

improperly installed

Check the actuator’s operating

mode and connect to the

control pressure line in

accordance to this operating

mode.

The rolling diaphragm is defect

Replace the rolling diaphragm

and springs

Manual emergency adjustment

is blocked

Set the manual emergency

adjustment into the correct

position (both position

indicators must be at the

starting point and be in the

same position).

There is not enough

positioning force available

Wrong spring pieces

(the spring range

of the

actuator is wrong)

Replace springs (actuator unit)

Stem sealing has a leak

Renew the stem sealing

The ventilation is plugged and

the air cannot escape from the

actuator unit

Screw cap must be disengaged

The actuator unit does not

ventilate sufficiently

Check the control adjustment