0 care and maintenance, 1 replacing the rolling diaphragm – ARI Armaturen DP34 EN User Manual

Page 19

0040504000 1210

Page 19

Operating and installation instructions

Pneumatic actuators - DP32 / DP33 / DP34

8.0 Care and maintenance

Maintenance and maintenance intervals have to be defined by the operator according to

the service conditions.

- For each operating mode, the actuator unit, if need be, should be freed from exterior dirt.

- The actuator unit may not be cleaned with high-pressure equipment or with aggressive

cleaning products, that are a health hazard, or with flammable cleaning products or

solvents.

- After cleaning, for example, an inspection should be carried out checking the sealings of

the actuator unit.

- In order to ensure smooth running, the operation device for the control air should be

furnished with a maintenance unit.

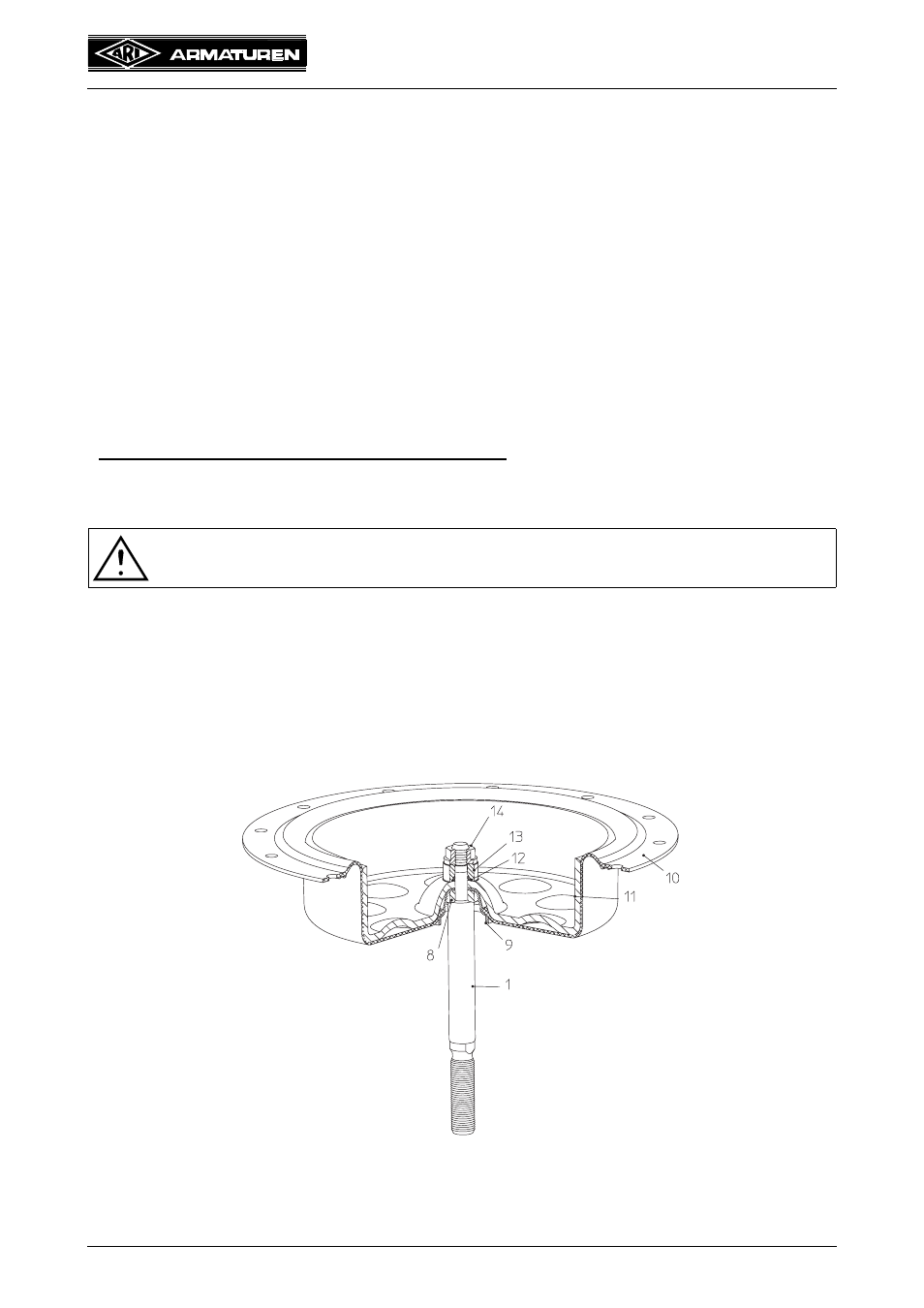

- The rolling diaphragm (pos. 10) and the stem guiding with O-ring-sealing are wearing

parts and must be replaced when necessary (see point 8.1).

- Actuators with manual emergency adjustment:

Lubricate with grease by using lubricating nipple (pos. 54).

8.1 Replacing the rolling diaphragm

- Remove the actuator from the valve, as described in point 7.0, and disassemble.

- Take out the construction units: stem (pos. 1) / diaphragm plate (pos. 11) /

rolling diaphragm (pos. 10) / diaphragm flange (pos. 9).

- Loosen the flange nut (pos. 14).

- Remove the diaphragm flange (pos. 9) .

- Replace the rolling diaphragm (pos. 10) and reassemble.

ATTENTION !

- When replacing the rolling diaphragme, the springs must be changed, too.

Fig. 21: „actuator stem extends by spring force“