Safe operating conditions, Schematic fusing, Mechanical interrupt switch – Red Lion RLY7 User Manual

Page 2: Wiring guidelines, Ordering information, Three phase heating application, Voltage control, Line, Derating curve, Input specifications

INPUT SPECIFICATIONS

1. Control Voltage Range: 4 to 32 VDC

2. Turn-on Voltage (Min.): 4 VDC

3. Turn-off Voltage (Max.): 1 VDC

4. Input Current (Max.): 15 mA

GENERAL SPECIFICATIONS

1. Isolation (Input to Output to Base): 4000 V

RMS

2. Operating Temperature Range: 0°C to 40°C

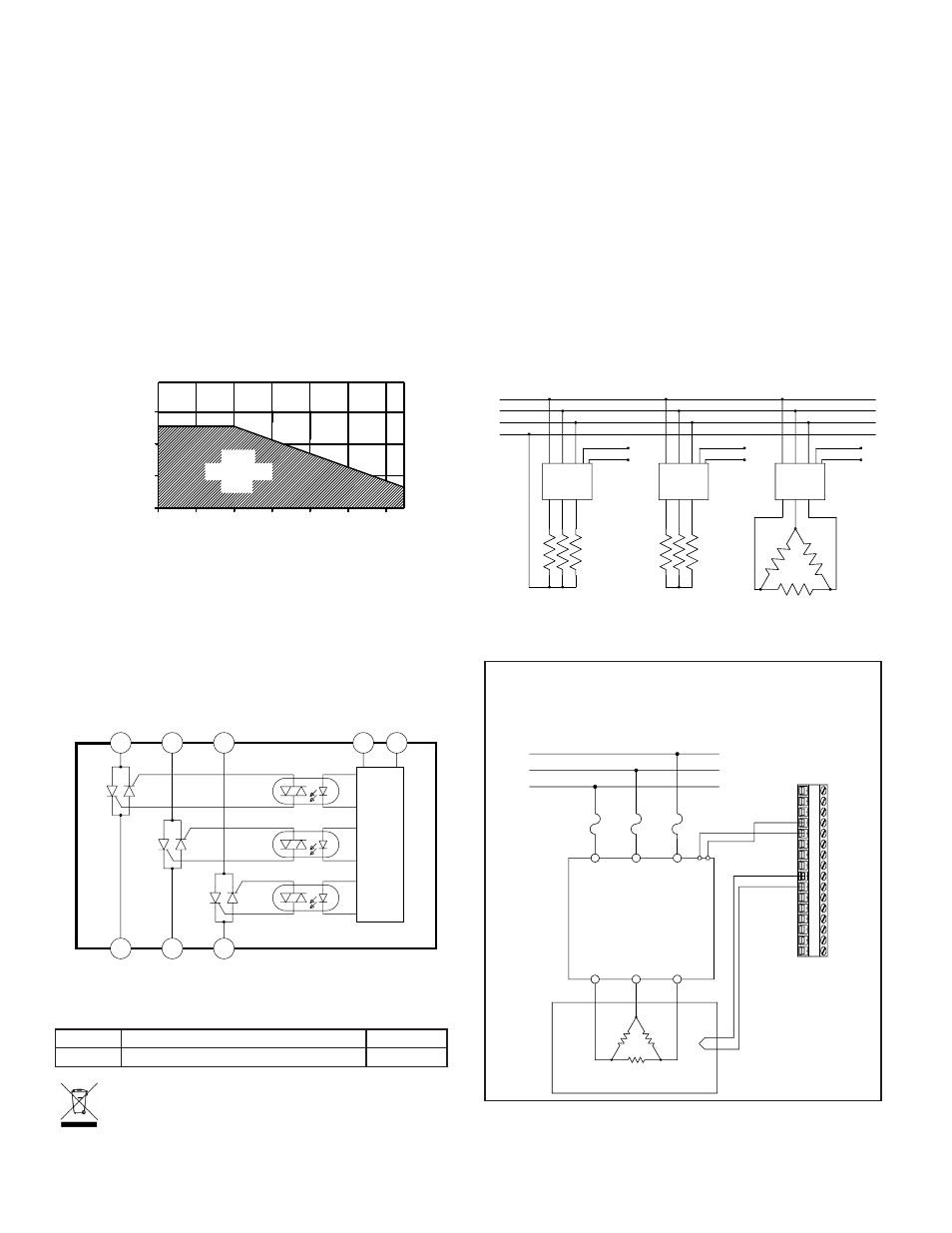

SAFE OPERATING CONDITIONS

The relay must always operate within the “Safe Operating Area” of the

Derating Curve Figure. Operations outside the Safe Operating Area will shorten

the life of, or cause permanent damage to, the relay. The ambient temperature

should be measured 1" (25 mm) below the relay (when mounted to a vertical

surface) and with all of the associated equipment operating.

It is strongly recommended that a 1" (25 mm) clearance is maintained on all

four sides of the relay. If the relays are mounted against each other, then the end

relays must be derated by an additional 10% (of the Derating Curve) and the

middle relays by 20%.

In small enclosures, adequate ventilation must be provided to assure proper

safe operating temperature. Accumulation of dust and dirt on the heat sink fins

will also affect heat dissipation. In extreme dust and dirt conditions, the relay

must be derated by an additional 20%.

SCHEMATIC

FUSING

Devices such as electromechanical circuit breakers and slow blow fuses

cannot react quickly enough to protect this relay in a shorted condition. Fast

“semiconductor fuses” with appropriate I

2

T ratings are strongly recommended.

MECHANICAL INTERRUPT SWITCH

The off-state leakage current of the power unit is 10 mA maximum. The

voltage level of the output will rise proportional to the resistance of the load due

to this leakage current. Full line voltage can be measured when the output is

connected to a high resistance load and the power unit is in the off-state.

A mechanical interrupt switch is recommended between the line voltage and

the load. The switch should be opened when servicing any part of the output

wiring. When measuring the off-state output voltage of the unit for correct

operation, load the output of the RLY7 with a small resistance (approximately

100 ohms).

WIRING GUIDELINES

The controlling device and the relay load should NEVER share the same

power feed. It is recommended that this relay be installed as close as possible to

the load to keep the power cable runs short. The control voltage can run over

distances in excess of 200 feet with shielded cable. If using shielded cable,

connect the shield to the minus “-” terminal of the control signal at one end only.

Zero

voltage

detector

L3

L2

L1

Voltage

Control

T3

T1

T2

LINE

ORDERING INFORMATION

MODEL NO.

DESCRIPTION

PART NUMBER

RLY7

Three Phase Din Rail Mount Solid State Relay

RLY70000

L1

L2

L3

N

without neutral

Star or Wye connection

Star or Wye connection

with neutral

Delta

Connection

T2

T1

T3

L2

L1

L3

Control

Control

Control

L3

L2

L1

T1

T3

T2

L1 L2 L3

T2 T3

T1

KILN

9

T1

T2

T3

13

16

15

14

11

12

10

-

+

Control

L1

L2

L3

L3

L2

L1

-

8

+

7

6

5

4

2

3

1

SSR DRIVE OUTPUT

MODEL TCU WITH

THREE PHASE HEATING APPLICATION

This application shows a Model TCU Temperature Controller regulating

the temperature of a drying kiln. The TCU has an SSR Drive Output

Module installed. This module controls the three phase relay directly.

Derating Curve

Safe

Operating

Area

0

10

20

30

20

30

40

50

60

70

80

Operating Load

Current (Amps RMS

)

Ambient Temperature (C°)

40

Do not dispose of unit in trash - Recycle