Emc installation guidelines, Installation environment, Installation – Red Lion GCM422 User Manual

Page 2

2

EMC INSTALLATION GUIDELINES

Although this unit is designed with a high degree of immunity to

ElectroMagnetic Interference (EMI), proper installation and wiring methods

must be followed to ensure compatibility in each application. The type of

electrical noise, source or coupling method into the unit may be different for

various installations. In extremely high EMI environments, additional

measures may be needed. Cable length, routing and shield termination are

very important and can mean the difference between a successful or a

troublesome installation. Listed below are some EMC guidelines for

successful installation in an industrial environment.

1. DC power to the unit should be relatively clean and within the specified

limits. Connecting power to the unit from circuits that power inductive

loads that cycle on and off, such as contactors, relays, motors, etc., should

be avoided. This will reduce the chance of noise spikes entering the DC

power connection and affecting the unit.

2. The shield (screen) pigtail connection should be made as short as possible.

The connection point for the shield depends somewhat upon the

application. Listed below are the recommended methods of connecting the

shield, in order of their effectiveness.

a. Connect the shield only at the unit to earth ground (protective earth).

b. Connect the shield to earth ground at both ends of the cable, usually

when the noise source frequency is above 1 MHz.

c. Connect the shield to common of the unit and leave the other end of the

shield unconnected and insulated from earth ground.

3. Never run Signal cables in the same conduit or raceway with AC power

lines, conductors feeding motors, solenoids, SCR controls, and heaters,

etc. The cables should be run in metal conduit that is properly grounded.

This is especially useful in applications where cable runs are long and

portable two-way radios are used in close proximity or if the installation is

near a commercial radio transmitter.

4. Signal cables within an enclosure should be routed as far away as possible

from contactors, control relays, transformers, and other noisy components.

5. In extremely high EMI environments, the use of external EMI suppression

devices, such as ferrite suppression cores, is effective. Install them on

Signal cables as close to the unit as possible. Loop the cable through the

core several times or use multiple cores on each cable for additional

protection. Install line filters on the power input cable to the unit to

suppress power line interference. Install them near the power entry point

of the enclosure. The following EMI suppression devices (or equivalent)

are recommended:

Ferrite Suppression Cores for signal cables:

Fair-Rite # 0443167251 (RLC #FCOR0000)

TDK # ZCAT3035-1330A

Steward #28B2029-0A0

Line Filters for input power cables:

Schaffner # FN610-1/07 (RLC #LFIL0000)

Schaffner # FN670-1.8/07

Corcom #1VR3

Note: Reference manufacturer’s instructions when installing a line filter.

6. Long cable runs are more susceptible to EMI pickup than short cable runs.

Therefore, keep cable runs as short as possible.

INSTALLATION ENVIRONMENT

The unit should be installed in a location that does not exceed the

maximum operating temperature and provides good air circulation. Placing

the unit near devices that generate excessive heat should be avoided.

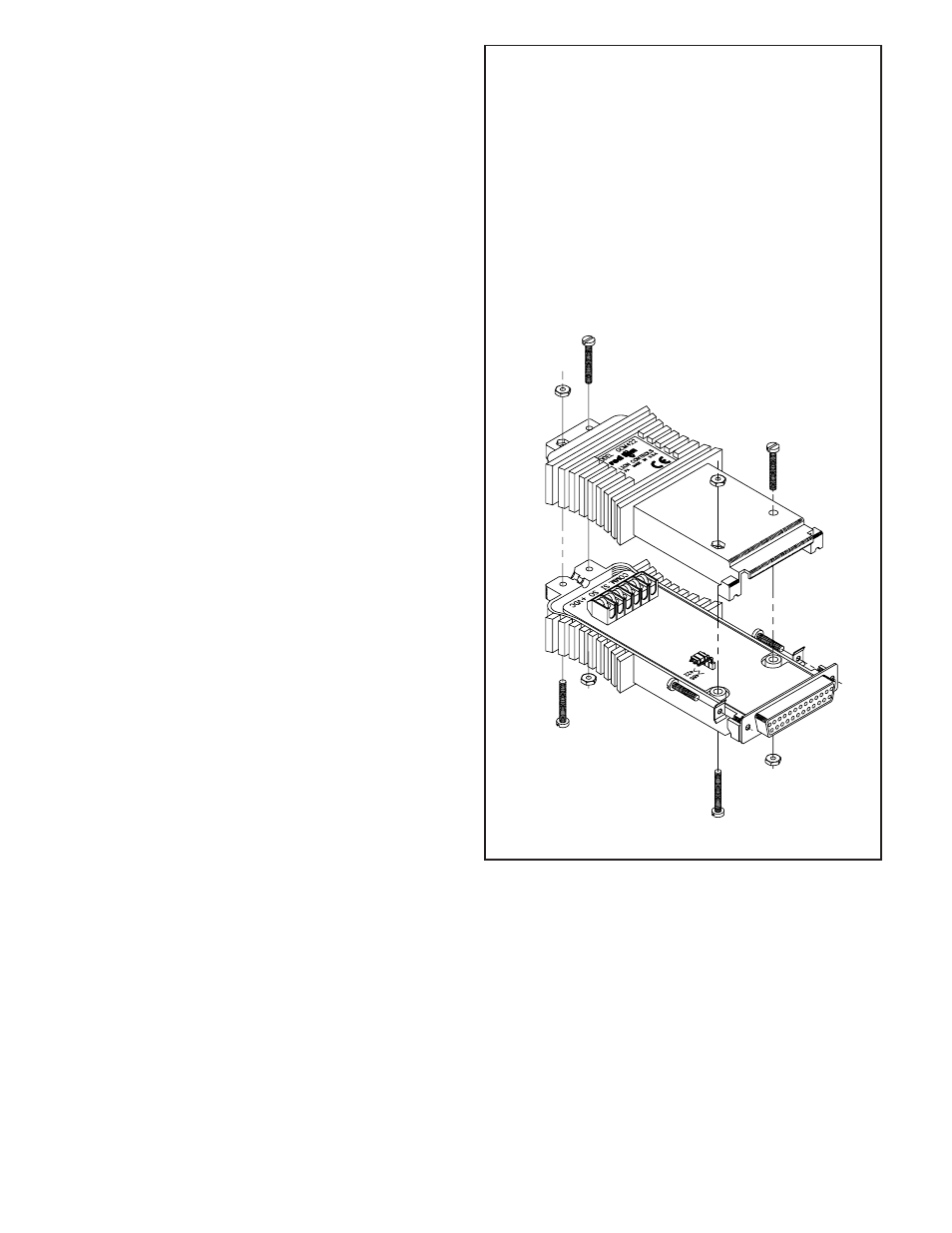

INSTALLATION

The power and 20 mA current loop connections should be made with 24

gauge, multi-conductor, shielded cable. Wire insulation should be stripped to

approximately 1/4 inch (stranded wires should be tinned with solder).

Accessing the terminal block and jumper is accomplished by removing the

four screws and nuts that hold the two case halves together. If the jumper

needs to be re-positioned, it should be done with NO power applied to the

module (module is shipped from factory in the 422 position). Connect the

power and 20 mA loop wires to the appropriate terminal block pins. The cable

is then routed through the groove at the rear of the module. Install the two

screws and saddle washers into the slots at the 25 pin D-connector. Position

the two case halves together, and secure with the four screws and nuts. Refer

to figure 1 below for assembly.

FIGURE 1