Exhaust vent (pvc and abs vent), Exhaust vent (stainless steel vent), Installation – State 520 User Manual

Page 11

Installation

11

│

Page

Excludes elbow termination, rain caps, or the 3” PVC Concentric Termination

For details on the vent connection to the Direct Vent Indoor models, refer to P.14

* For each elbow added, deduct 5 ft. from max. vent length.

‐Exhaust vent (PVC and ABS vent) ‐

The Direct Vent Indoor models can be connected with PVC or ABS venting (temperature rated up to

149°F). However, the manufacturer recommends PVC (or ABS) venting certified to ULC S636 standards.

Item

Material

United States

Canada

Exhaust pipe and

Fittings

Schedule 40 PVC

ANSI/ASTM D1785

ULC S636 Certified

Materials Only

PVC‐DWV

ANSI/ASTM D2665

Schedule 40 CPVC

ANSI/ASTM F441

Schedule 40 ABS‐DWV

ANSI/ASTM D2661

Pipe Cement/Primer

PVC

ANSI/ASTM D2564

CPVC

ANSI/ASTM F493

ABS

ANSI/ASTM D2235

NOTE: Do NOT Use Cellular Foam Core Pipe

The maximum length of exhaust vent piping must not exceed 50 ft. for 4” venting and 25 ft. for

3” venting (deducting 5 ft. for each elbow used in the venting system). Do not use more than 5

elbows for 4” venting and 2 elbows for 3” venting.

When the horizontal vent run exceeds 5 ft., support the vent run at 3 ft. intervals with overhead

hangers.

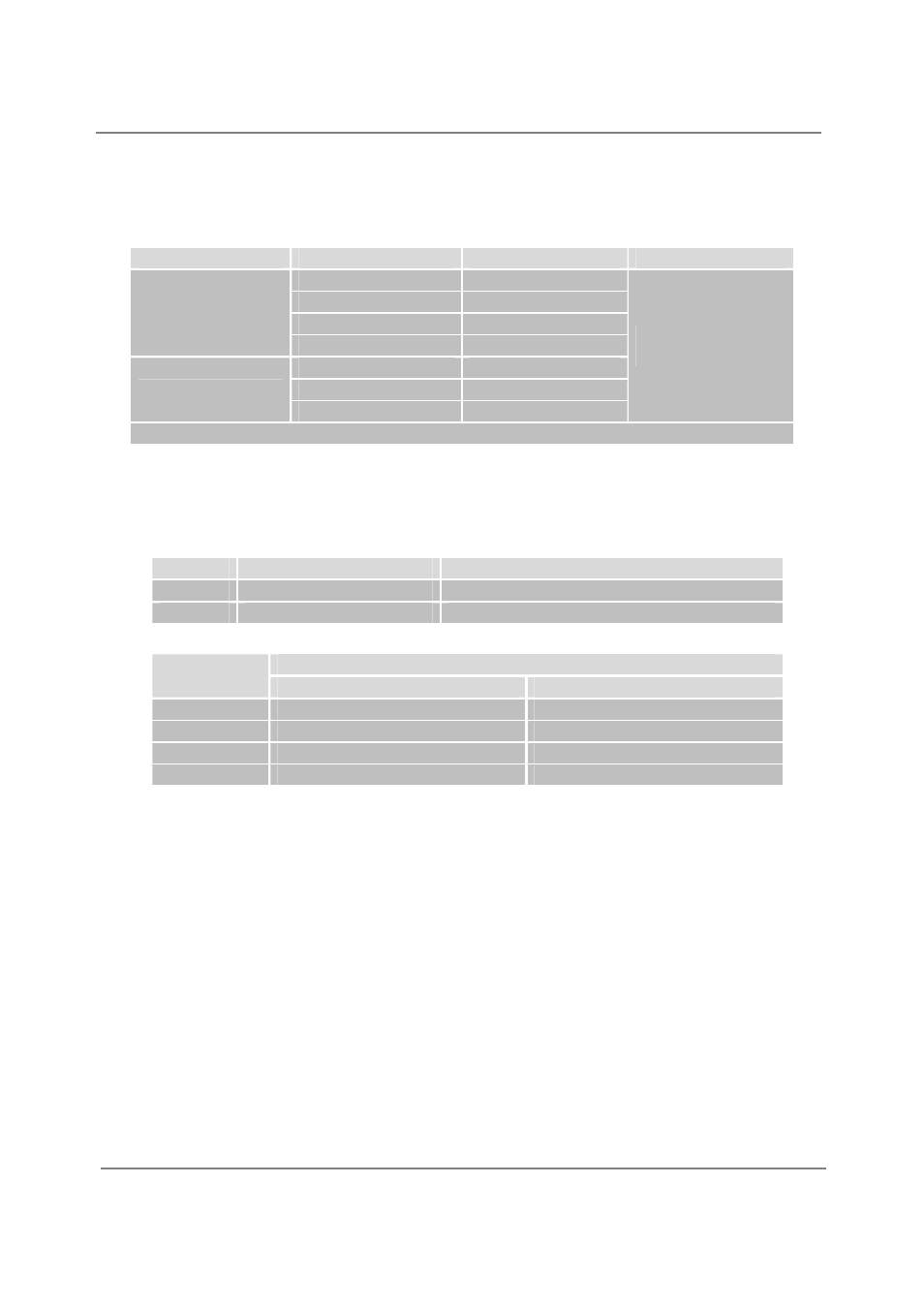

Diameter

Max. No. of Elbow

Max. Vertical and Horizontal (Total) Vent Length

3”

2

25 ft.

4”

5

50 ft.

No. of Elbows

Max. Vertical or Horizontal Length

3” venting

4” venting

0

25 ft.

50 ft.

1

20 ft.

45 ft.

2

15 ft.

40 ft.

5

N/A

25 ft.

This is a Category IV appliance and must be vented accordingly. The vent system must be sealed air tight.

All seams and joints without gaskets must be sealed with high heat resistant silicone sealant or UL listed

aluminum adhesive tape having a minimum temperature rating of 160°F. For best results, a vent system

should be as short and straight as possible.

The Direct Vent Indoor models are a Category IV appliance and must be vented accordingly with

any 4” vent approved for use with Category III/IV or Special BH type gas vent.

The manufacturer recommends the “T‐Vent” line manufactured by TAKAGI (Refer to Takagi’s

“T‐Vent” brochure for details). However, the following are also UL listed manufacturers: ProTech

Systems Inc. (FasNSeal), Flex‐L Inc., Z‐Flex Inc. (Z‐Vent III), Metal‐Fab Inc., and Heat‐Fab Inc. (Saf‐

T Vent).

Follow the vent pipe manufacturer’s instructions when installing the vent pipe.

‐Exhaust vent (Stainless steel vent)‐