Installation for direct vent indoor models, Venting instructions, General – State 520 User Manual

Page 10

Installation

10

│

Page

Improper venting of this appliance can result in excessive levels of carbon monoxide

which can result in severe personal injury or death.

When installing the vent system, all applicable national and local codes must be

followed. If you install thimbles, fire stops or other protective devices and they

penetrate any combustible or noncombustible construction, be sure to follow all

applicable national and local codes.

INSTALLATION FOR DIRECT VENT INDOOR MODELS

The Direct Vent Indoor models are equipped with a thermistor and hi‐limit switch for the exhaust gas,

detecting excess temperatures within the flue and enabling the unit to safely stop operations if needed.

These components are always monitoring exhaust gas conditions in order to prevent heat damage to

PVC (Plastic) venting if PVC is used.

If the exhaust gas temperature exceeds 140°F, these components will enable the unit to safely stop

operations. (For the Outdoor model, these components are not available since there’s no exhaust

venting required.)

The Direct Vent Indoor model requires a

4” make‐up intake air supply pipe. The

intake pipe must be sealed airtight.

Air supply pipe can be made of ABS, PVC,

galvanized steel, corrugated stainless

steel, or Category lll / IV stainless steel.

Sidewall venting is recommended for the

Direct Vent Indoor model. Vertical

venting (roof termination) is acceptable.

The

manufacturer

recommends

running the exhaust vent and the

intake pipe as parallel as possible.

The PVC adaptor is used to make the

connection between the Direct Vent

Indoor model vent collar and PVC

vent pipe easier and for maintenance

purposes.

VENTING INSTRUCTIONS

‐General‐

The Direct Vent Indoor models must be vented in accordance with the section “Venting of Equipment"

of the latest edition of the National Fuel Gas Code: ANSI Z223.1/NFPA 54 in the United States and/or

Section 7 of the CAN/CSA B149.1 Natural Gas and Propane Installation Code in Canada, as well as

applicable local building codes.

The use of venting materials approved for Category III/IV appliances is recommended whenever possible.

However, the Direct Vent Indoor models may also be vented with plastic pipe materials such as PVC. For

details, please refer to the Exhaust Vent (PVC Vent) section on p. 11. Vent installations in Canada which

utilize plastic vent systems must use venting that complies with ULC S636.

WARNING

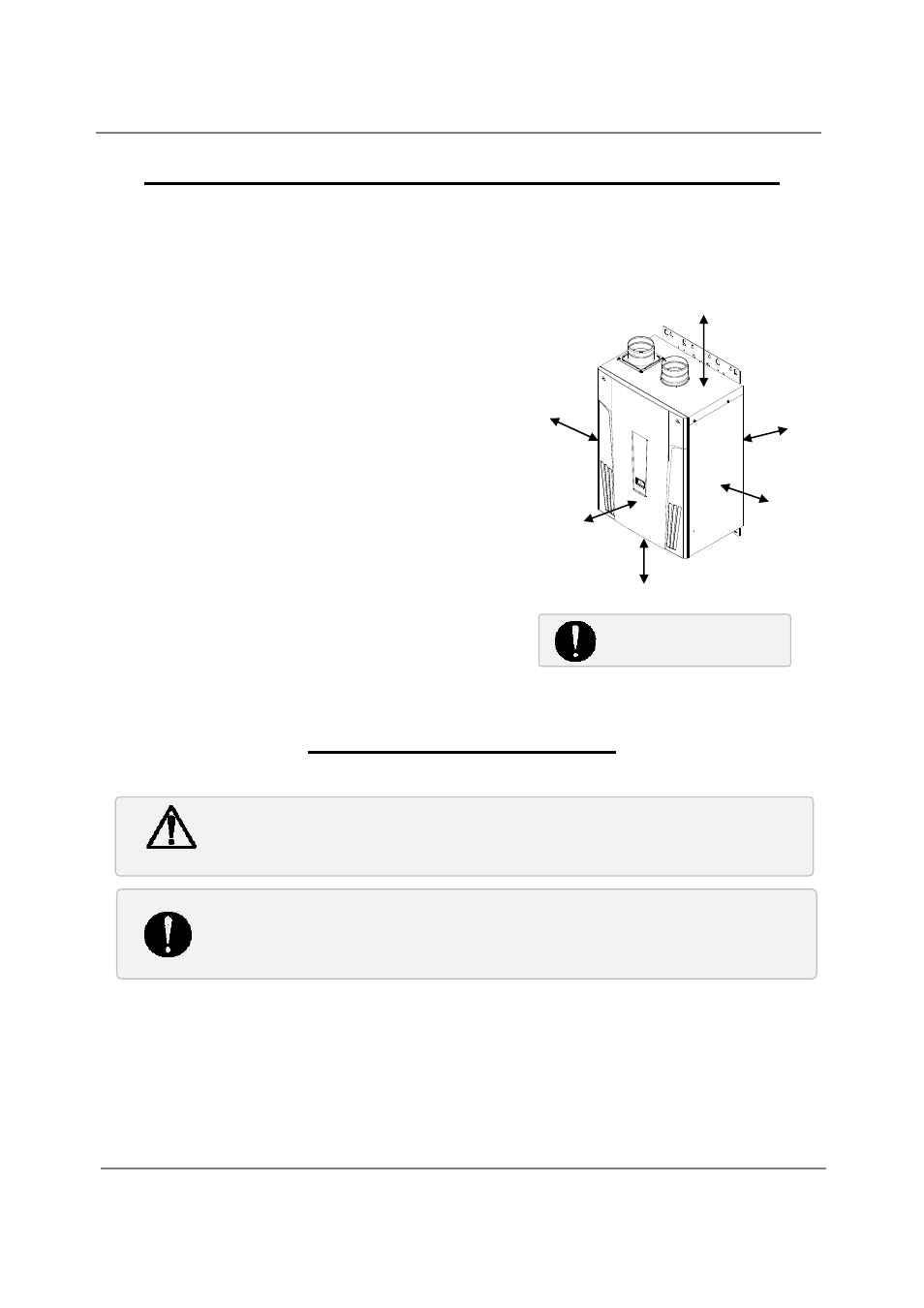

Top 12”

Side 3”

Back 0.5”

Side 3”

Front 4”

(24” Recommended

for Maintenance)

Bottom 12”

Keep the clearances.