State SBB75 76NE User Manual

Page 6

6

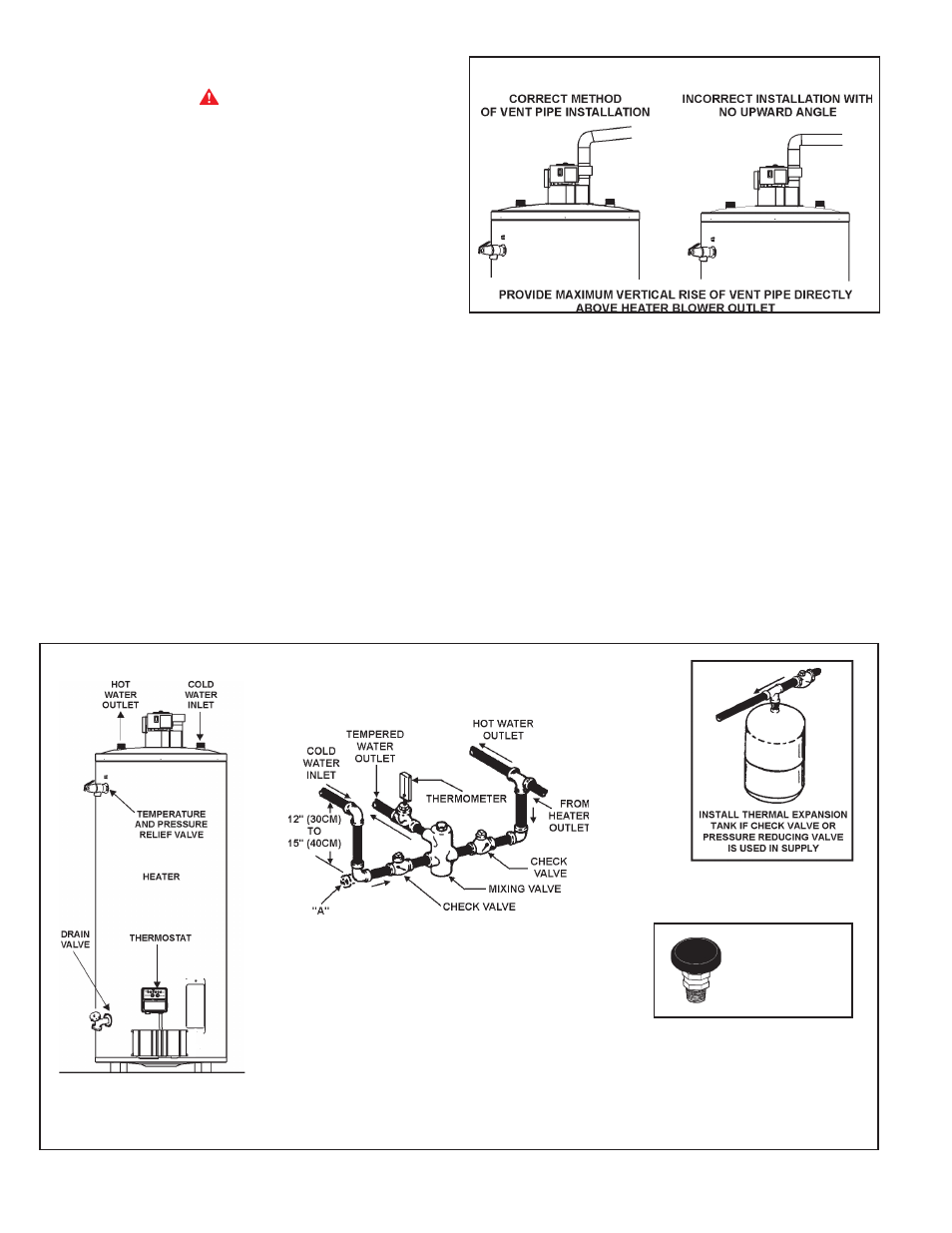

CAUTION: IF BUILDING COLD WATER SUPPLY HAS A BACK-FLOW

PREVENTER, CHECK VALVE OR WATER METER WITH CHECK

VALVE, PROVISIONS FOR THERMAL EXPANSION OF WATER IN

THE HOT WATER SYSTEM MUST BE PROVIDED.

FIGURE 3.

CIRCULATING RETURN LINE CONNECTIONS

TEMPERED WATER LOOP, IF USED, CONNECT TO POINT "A".

STORED TEMPERATURE WATER LOOP, IF USED, CONNECT TO

COLD WATER INLET

WARNING

TEMPERATURE SETTING SHOULD NOT EXCEED SAFE

USE TEMPERATURE AT FIXTURES. SEE TEMPERATURE

REGULATION ON PAGE 11. IF HIGHER PREHEAT

TEMPERATURES ARE NECESSARY TO OBTAIN

ADEQUATE BOOSTER OUTPUT, ADD AN ANTI-SCALD

VALVE FOR HOT WATER SUPPLIED TO FIXTURES.

SINGLE TEMPERATURE

VENTING

WARNING

THE INSTRUCTIONS IN THIS SECTION ON VENTING MUST BE

FOLLOWED TO AVOID CHOKED COMBUSTION OR RECIRCULATION

OF FLUE GASES. SUCH CONDITIONS CAUSE SOOTING OR RISKS

OF FIRE AND ASPHYXIATION.

This water heater must be protected from freezing downdrafts.

Remove all soot or other obstructions from the chimney that will retard

a free draft.

Type B venting is recommended with these water heaters.

This water heater must be vented in compliance with all local codes, the

current edition of the National Fuel Gas Code, ANSI Z223.1/NFPA 54,

and with the Category I Venting Tables.

In Canada, venting shall conform to the requirements of the current

edition of the CAN/CSA B149.1-00 installation code.

If any part of the vent system are exposed to ambient temperatures below

35 degrees F (2 degrees C) it must be insulated to prevent condensation.

• Do not connect the heater to a common vent or chimney with solid

fuel burning equipment. This practice is prohibited by many local

building codes as is the practice of venting gas fired equipment to

the duct work of ventilation systems.

• Where a separate vent connection is not available and the vent

pipe from the heater must be connected to a common vent with an

oil burning furnace, the vent pipe should enter the smaller common

vent or chimney at a point above the large vent pipe.

FIGURE 2.

VENT CONNECTION

Vent connections must be made to an adequate stack or chimney. Size

and install proper size vent pipe. Do not reduce pipe size to less than

that of the blower outlet.

Horizontal runs of vent pipe must have a minimum upward slope toward

the chimney of 1/4 inch per foot (2cm per meter). Dampers or other

obstructions must not be installed in between the heater and the blower.

Be sure that the vent pipe does not extend beyond the inside wall of

the chimney.

Where a continuous or intermittent back draft is found to exist, the

cause must be determined and corrected. A special vent cap may be

required. If the back draft cannot be corrected by the normal methods or

if a suitable draft cannot be obtained, a blower type flue gas exhauster

must be employed to assure proper venting and correct combustion.

MIXING VALVE APPLICATION FOR TWO TEMPERATURE WATER

VACUUM RELIEF

VALVE

*INSTALL PER

LOCAL CODES.