Periodic maintenance (cont’d), Service, Draining – State GS6 65 XRRT User Manual

Page 20: Drain valve washer replacement, Temperature-pressure relief valve operation, Anode rod inspection

Periodic Maintenance (cont’d)

Service

If a condition persists or you are uncertain about the oper-

ation of the water heater, let a qualified person check it

out. Call the local utility and/or plumbing contractor.

Draining

The water heater should be drained if being shut down

during freezing temperatures. Also periodic draining and

cleaning of sediment from the tank may be necessary.

1. Turn the gas control knob to the “OFF” position.

2. CLOSE the cold water inlet valve to the water heater.

3. OPEN a nearby hot water faucet and leave open to

allow for draining.

4. Connect a hose to the drain valve and terminate to an

adequate drain.

5. OPEN the water heater drain valve to allow for tank

draining.

NOTE: If the water heater is going to be shut down

and drained for an extended period, the drain valve

should be left open with hose connected allowing

water to terminate to an adequate drain.

6. Close the drain valve.

7. Follow instructions in the “Filling The Water Heater”

section.

8. Follow the lighting instructions in the “Lighting” sec-

tion to restart the water heater.

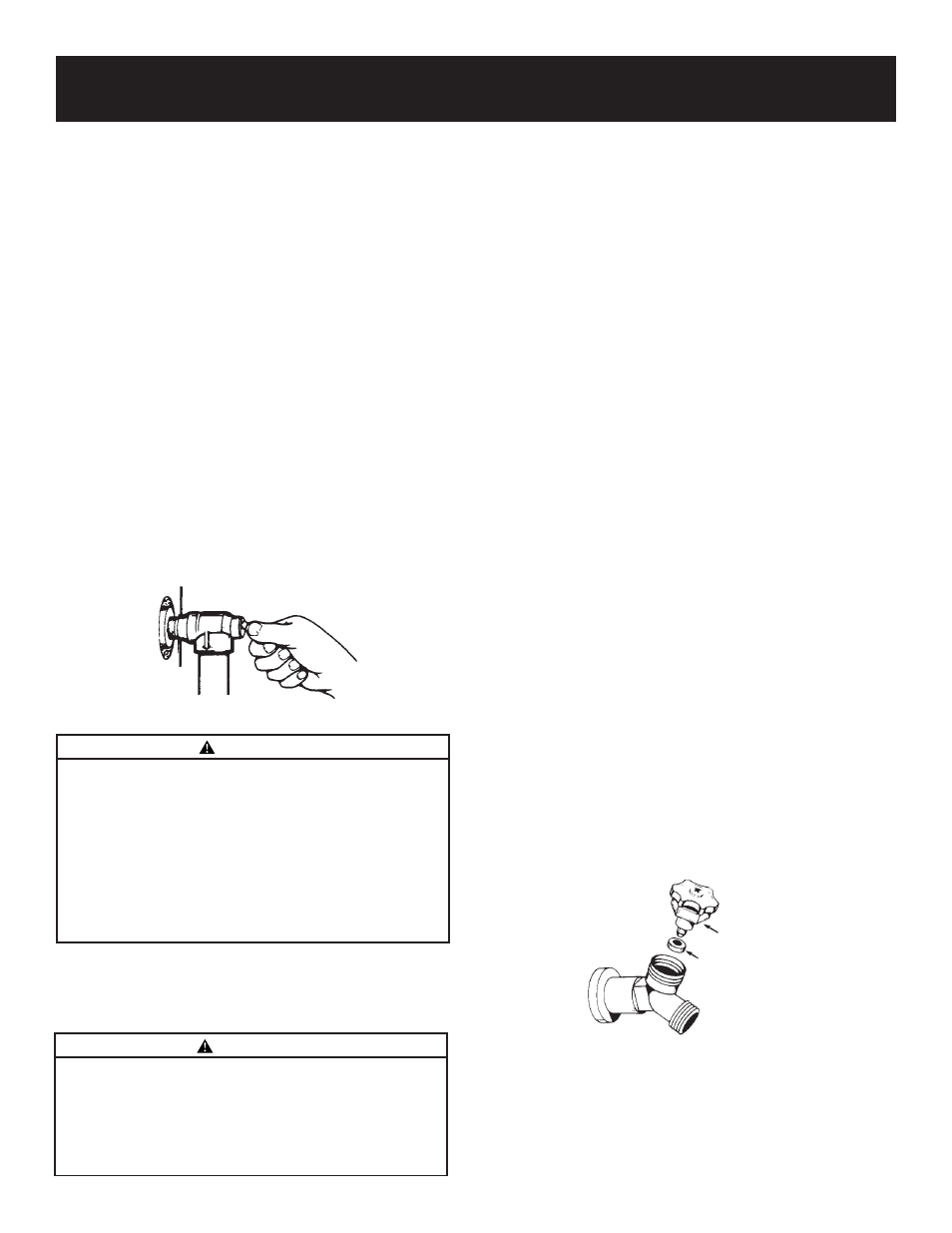

Drain Valve Washer

Replacement

NOTE: For replacement, use a

17

⁄

32

″ x

13

⁄

64

″ x

1

⁄

8

″ thick wash-

er available at your nearest hardware store. For ordering

replacement washers, refer to the “Repair Parts” section.

1. Turn “OFF” gas supply to water heater.

2. Follow “Draining” instructions.

3. Turning counter clockwise, remove the hex cap below

the screw handle.

4. Remove the washer and put the new one in place.

5. Screw the handle and cap assembly back into the

drain valve and retighten using a wrench. DO NOT

OVER TIGHTEN.

6. Follow instructions in the “Filling The Water Heater”

section.

7. Check for leaks.

8. Follow the lighting instructions in the “Lighting” sec-

tion to restart the water heater.

Failure to install and maintain a new properly listed tempera-

ture-pressure relief valve will release the manufacturer from

any claim which might result from excessive temperature or

pressure.

Temperature-Pressure Relief

Valve Operation

The temperature-pressure relief valve must be manually

operated at least once a year.

20

HANDLE AND CAP

ASSEMBLY

TEMPERATURE-PRESSURE

RELIEF VALVE

DISCHARGE PIPE

WASHER

WARNING

When checking the temperature-pressure relief valve

operation, make sure that (1) no one is in front of or

around the outlet of the temperature-pressure relief

valve discharge line, and (2) that the water manually dis-

charged will not cause any property damage because the

water may be extremely hot.

If after manually operating the valve, it fails to complete-

ly reset and continues to release water, immediately

close the cold water inlet to the water heater, follow the

draining instructions, and replace the temperature-pres-

sure relief valve with a new one.

WARNING

If the temperature-pressure relief valve on the appli-

ance weeps or discharges periodically, this may be due

to thermal expansion. Your water heater may have a

check valve installed in the water line or a water meter

with a check valve. Consult the water supplier and/or

plumbing inspector for further information. Do not

plug the temperature-pressure relief valve.

Anode Rod Inspection

The anode rod is used to protect the tank from corrosion.

Most hot water tanks are equipped with an anode rod. The

submerged rod sacrifices itself to protect the tank. Instead

of corroding the tank, water ions attack and eat away the

anode rod. This does not affect the water’s taste or color.

The rod must be maintained to keep the tank in operating

condition.

Anode deterioration depends on water conductivity, not nec-

essarily water condition. A corroded or pitted anode rod

indicates high water conductivity and should be checked

and/or replaced more often than an anode rod that appears

to be intact. Replacement of a depleted anode rod can

extend the life of your water heater. Inspection should be

conducted by a qualified technician, and at a minimum

should be checked annually after the warranty period.