A.R.I. DG 101 EN User Manual

Page 2

A.R.I FLOW CONTROL ACCESSORIES Ltd.

Kfar Charuv 12932 Israel Tel. 972-4-6761803 Fax. 972-4-6763402

WWW.ARIVALVES.COM [email protected]

MAINTENANCE INSTRUCTIONS DG-10 1”

EnM-DG101-10

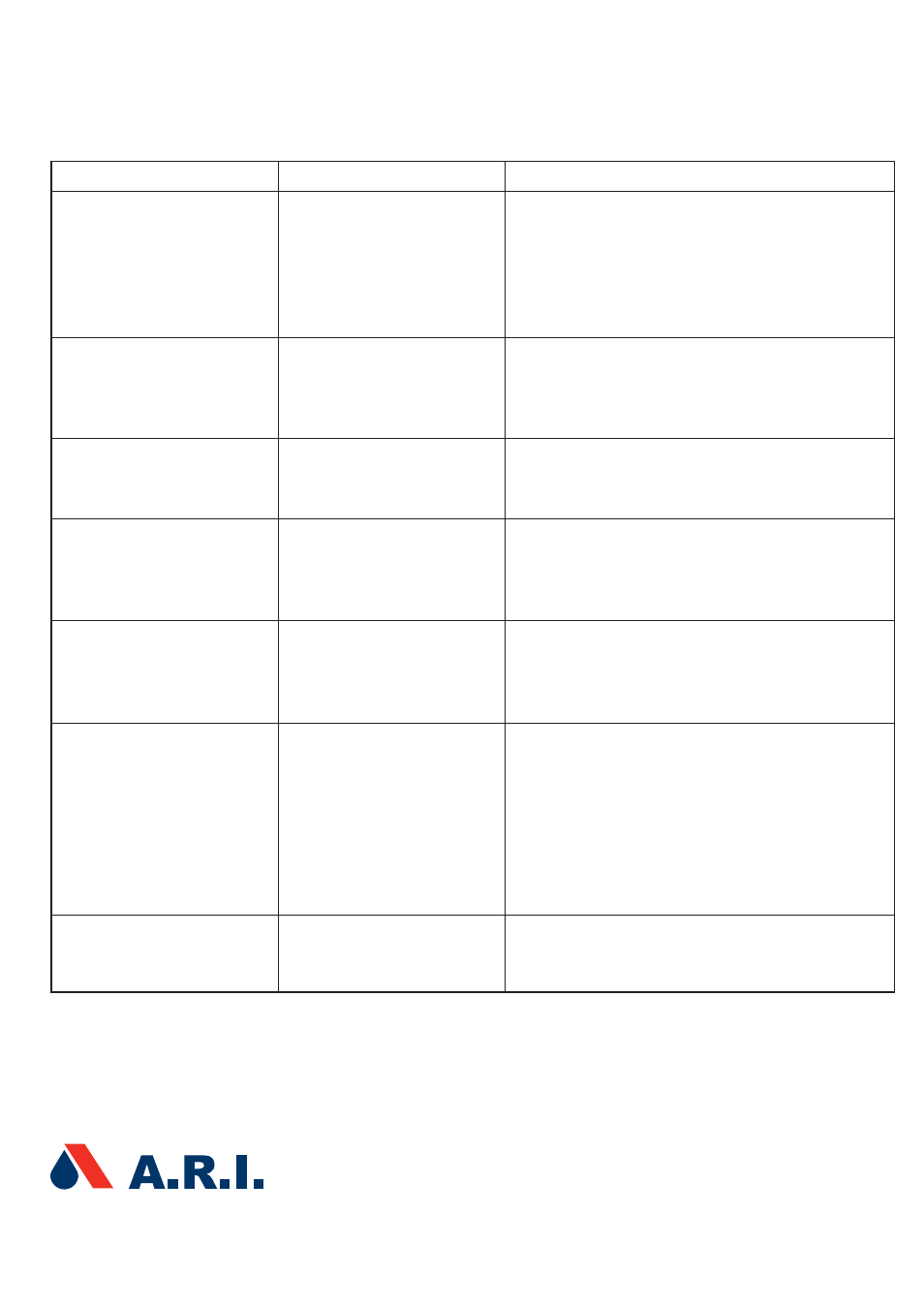

TROUBLESHOOTING

Easy to replace: gently pry off the outlet with

screwdriver Pressure insert the new right angle

using a plastic hammer.

Replacement part can be ordered from A.R.I.

Note:

The part is not mandatory for the function

of the valve.

Valve was hit or mishandled.

Right angle outlet is broken.

CORRECTIVE ACTION

CAUSE

SYMPTOM

D040 has 3/8” female thread.

2” D040 has 1¼” female thread.

End of pipe must be left open in order for valve to

function.

End user needs to connect a

drainage pipe from the valve

outlet in order to drain

excess water.

Outlet thread size needed in

order to attach a drainage

hose.

ARI offers an approved 316 stainless screen that

threads into the 2" valve.

GSM in California has made one for the 1” valve.

This is an above ground

installation.

Built-in plastic screen is not

accepted by health

department.

We provide several alternatives for those who do

not want plastic.

Offer the cast iron or

stainless steel body.

Also offer the bronze or

stainless steel base.

Plastic body and/or base not

acceptable.

Open the valve. Clean and check integrity of the

sealing mechanism and O-ring seals.

This is normal at start up

and during pressure test.

Could be debris in the

sealing mechanism.

Valve spits water.

Check for cross-threading.

Replace bottom of valve or offer the cast metal

base.

Plastic threads stripped.

Valve leaks from threads.

Check line pressure. It needs at least 3 psi to seal

tight.

Is the valve on a booster pump? Can be installation

issue if valve is level with the water level in a tank -

there is no pressure to seal.

Open valve and clean sealing mechanism, check

the rolling seal and o-rings for wear or tear.

Replace if necessary.

Line pressure issues,

(inadequate pressure),

or debris lodged in seal or

o-rings.

Valve is continuously

leaking.