Operation – Yetter 2984 Series Generation II Maverick Opener User Manual

Page 33

33

OPERATION

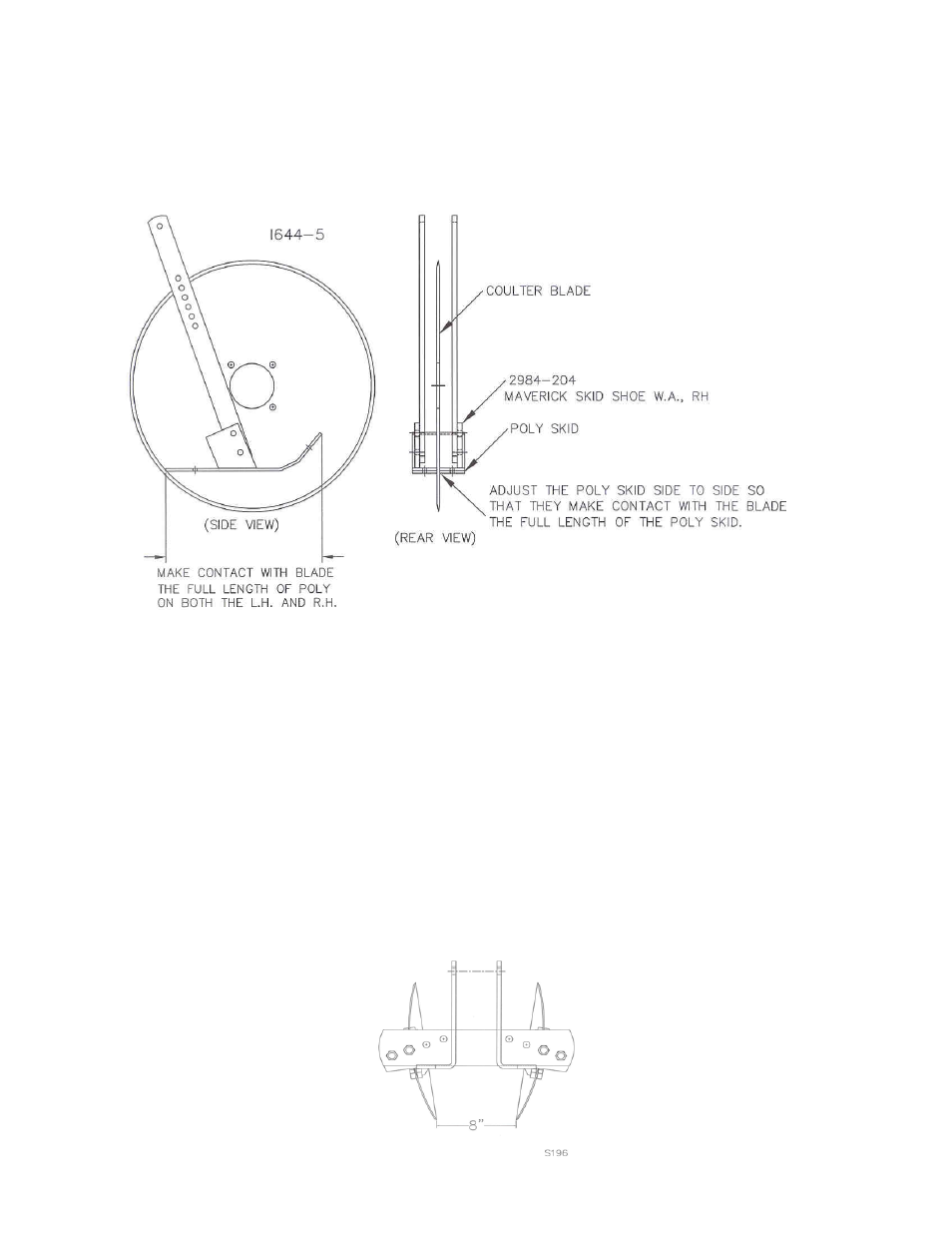

STEP 4. Adjustment of the “SKID SHOE” soil distribution guard/depth control is important for proper

placement of fertilizer and keeping soil from sticking to the coulter blade. Depth adjustment setting will

depend on coulter blade diameter and coulter blade settings. The lower the “SHOE” is on the blade, the

shallower the fertilizer will be placed. The higher the “SHOE” is on the blade, the deeper the fertilizer will be

placed. Soil disruption setting is controlled with the side to side adjustment of the “SHOE”. The poly shoe

should just touch the blade, front to back of the “SHOE”.

STEP 5. Adjust the residue manager to move crop residue aside and not move any soil. Adjustments to

the residue manager may have to be made when changing field conditions and type and amount of residue.

ROW CLEANER DO’s AND DON’T’s

1. DO NOT move soil, Residue Managers are designed to move crop residue only.

2. DO NOT operate toolbar at slow speeds, ground speed affects how aggressive the spoke

wheels are; operate at sufficient speed (5-7 mph) to maintain good residue flow.

3. DO NOT expect 100% of crop residue to be cleared, it is not necessary and would

necessitate engaging the soil. The width of path cleared depends on ground conditions,

depth setting and ground speed.

4. DO expect to see wheels occasionally quit turning, indicates ideal (shallow) setting which is

not moving soil.

5. DO adjust toolbar frame height 21”-24” and drawbar correctly. Very important to ensure

Maverick Opener will follow ground contours properly.

6. DO adjust Maverick Opener down pressure kit correctly to prevent excessive depth.

STEP 6. Adjust the Sealing Discs/Wheels. The width and height of the mound/berm depends on ground

conditions, depth setting, spring tension, blade angle and ground speed. A popular setting for the blade

adjustment is 8” at the rear of the blades, equal distance from the center of the row.