Final check, Final check -21, Assembly – Alamo Interstater FC-FL-0001 User Manual

Page 105: Assembl y

ASSEMBLY

INTERSTATER 03/09

Assembly Section 3-21

© 2009 Alamo Group Inc.

ASSEMBL

Y

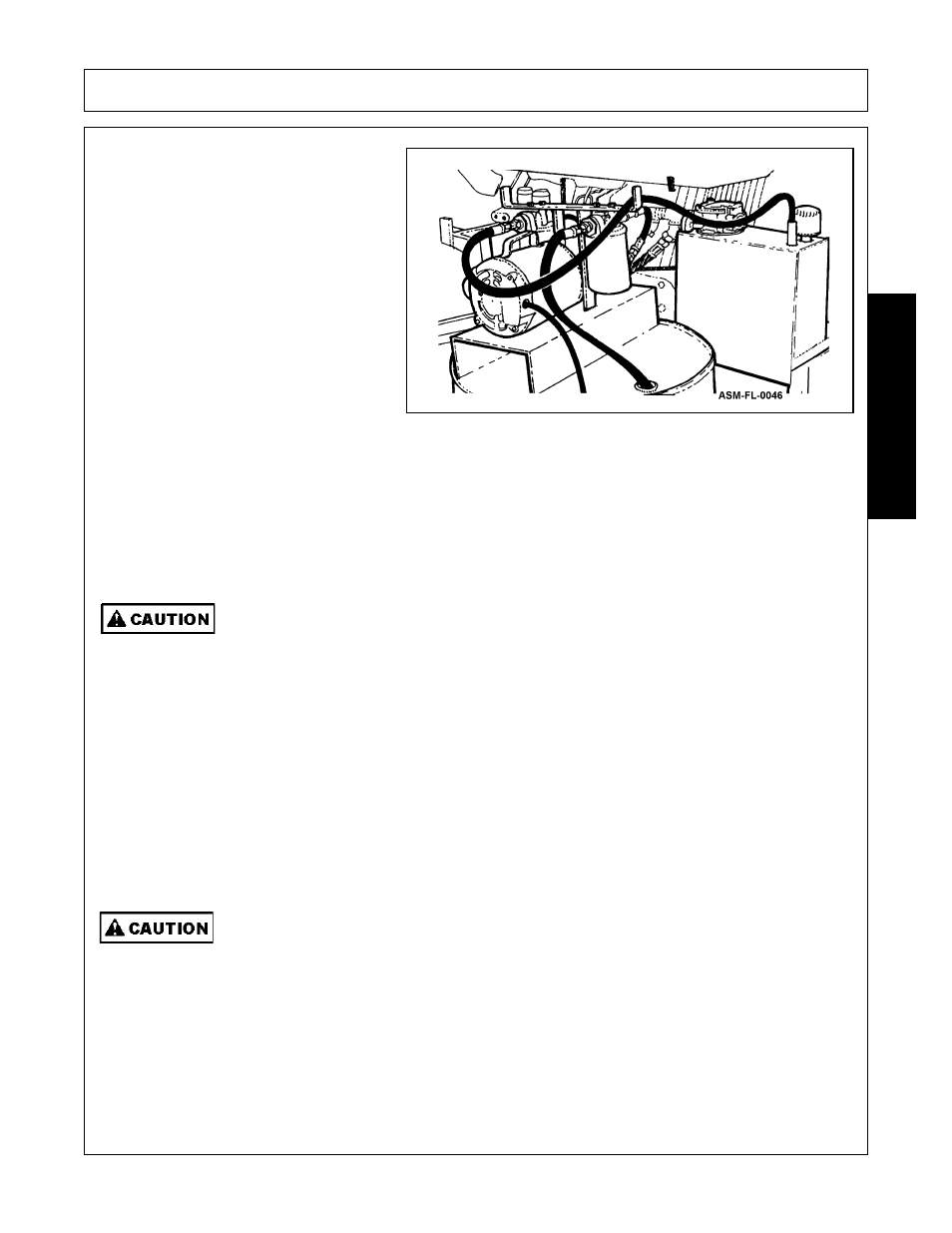

Filter buggies or carts are commercially

available for hydraulic system clean-up.

These consist of a high-efficiency, high-

capacity filter, a circulating pump, a drive

motor, and hoses for connecting the

overhauled machine’s hydraulic system.

ASM-FL-0048

After the first 10 hours of operation, replace

the hydraulic filter with a new one. An extra

Filter Element is provided for you. Refer to

the Operation and Maintenance Section for

instruction.

7. After the Interstater mower is completely

assembled to the tractor and with the wings

on the ground, fill the mower hydraulic tank

above the oil level sight gauge approximately 5" or 1" below the top of the tank.

8. With mower ON/OFF switches in “ON” position and tractor fuel cut off, crank engine for about 30 to 45

seconds to allow oil to fill pumps and motors. Check the oil level in the sight gauge. If no oil is seen add oil to

bring the level up to the sight gauge. NOTE: Do not fill the tank with oil above the level of the sight gauge.

Over filling the tank with oil after the initial filling may result in oil being discharged through the air filter on top of

the hydraulic tank. Start the tractor and run it for 2 minutes and then turn it off. Again check the oil level in the

sight gauge. If the oil level is in the sight gauge, the unit is ready to run. If no oil is seen, add oil to bring the

level up to the sight gauge.

Remove all foreign objects and stand clear of cutter units. DO NOT GET NEAR ROTATING

KNIVES!

NOTE: On tractor hydraulic powered circuit only, make certain that there is full flow from tractor hydraulic

system to control valve. Refer to tractor manual.

9. After hydraulic system is fully charged and functioning properly, switch cutter units on, then speed engine up

to 540 RPM PTO speed. Maintain this speed for about 5 minutes. Check complete INTERSTATER, look for

any leaks, loose connections, or anything that could cause premature wear or failure.

FINAL CHECK

Run INTERSTATER for about 1/2 hour at full speed. Check for leaks and vibrations. Frequently check oil

temperature. Make certain it does not exceed 180 deg.

NOTE: When raising wings, make certain there is no interference with mower, frame, cylinders or tractor. Lift

wings slowly.

DO NOT leave unit unattended, and COMPLY WITH ALL WARNING DECALS.

If unit starts to make unusual noise, stop unit and check oil level. Also check for frothy oil which would indicate

a leak on suction side of system.