Quick Fuel Technology SUPER STREET SERIES CARBURETORS User Manual

Page 3

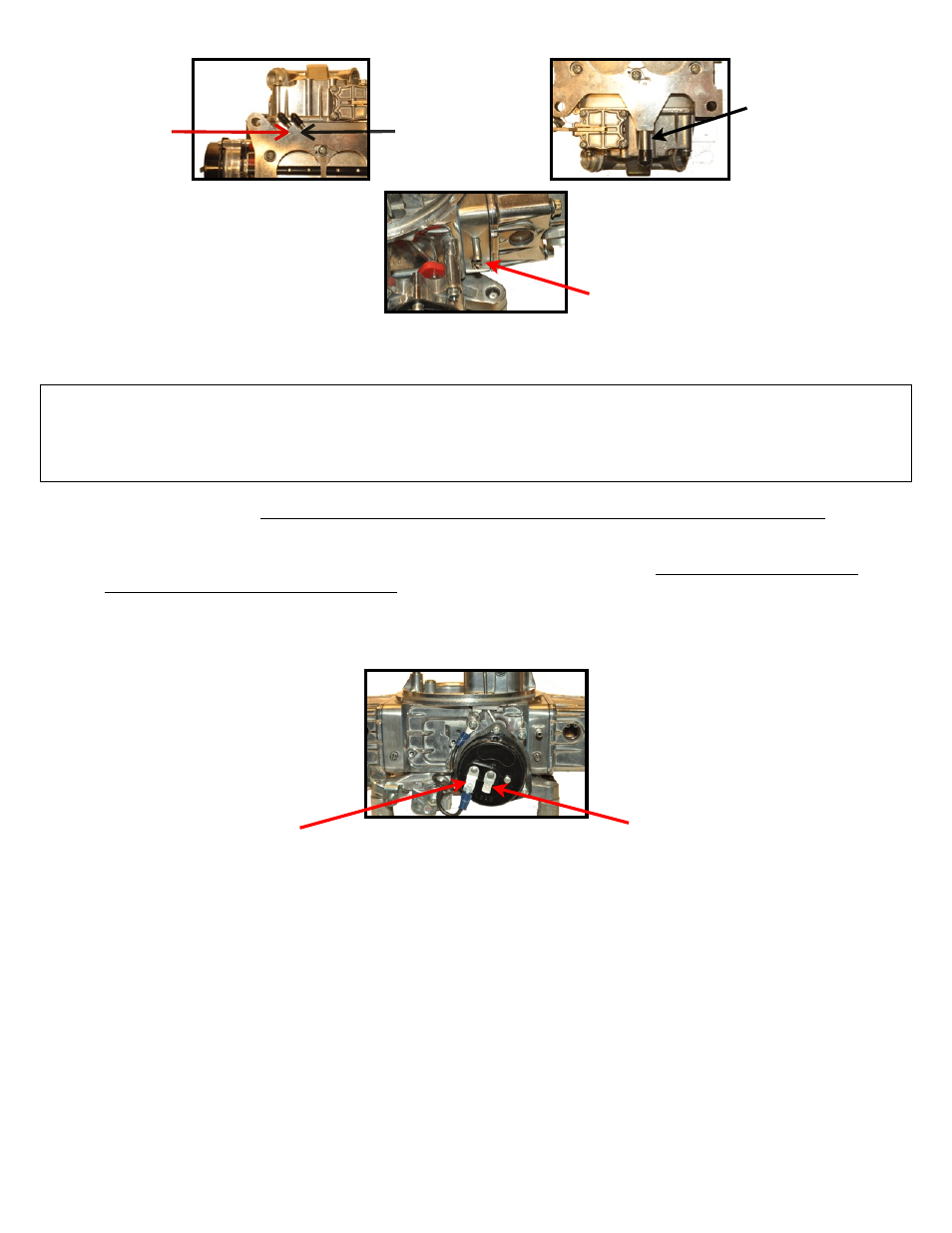

Distributor vacuum advance may also be connected to the tube in the primary metering block.

!

Manifold vacuum is typically used for transmission modular or any accessory

that requires a full manifold vacuum signal, i.e. heat and/or A/C control, vacuum actuated fresh air induction, etc. . The

Ported or timed vacuum is typically used for the vacuum advance canister on the distributor if applicable. NOTE: some

distributor vacuum advance canisters require full manifold vacuum, not ported or timed vacuum.

Check the specifications for your distributor.

8. Install fuel inlet fittings DO NOT USE TEFLON® TAPE ON INVERTED FLARE FUEL INLET FITTINGS. Clean

threads and flare of any dirt and debris before installation. Check to be certain the fuel inlet fittings in the fuel bowl

are tight, then install the fuel line nuts. Tighten sufficiently to prevent fuel leakage.

9. Connect positive (+) wire for electric choke to an key on 12 volt voltage source. DO NOT CONNECT TO THE

BATTERY SIDE OF THE IGNITION COIL. Preferably check voltage with a volt meter to determine the correct

voltage. NOTE: battery voltage will be 12 volts or greater. You need to recheck the voltage reading when the engine

is running to be certain the voltage does not drop below 12.6 volts. (Some engines use a field wire from the

alternator that only produces 9.5 volts which does not allow the choke to operate properly.)

Starting the Engine

1. Reattach the negative battery cable

2. You are now ready to start the engine.

3. Before attempting to start; the fuel bowls need to be filled with fuel. Whether you have an electric fuel pump or a

mechanical pump, it is necessary to operate the fuel pump for 15 seconds or so, a couple of 10 second cranks for

mechanical pumps, to enable the bowls to fill with fuel.

4. Before starting the engine make an initial check of the float level. If fuel is not visible in the sight glass. This

carburetor was pre-set at the factory to be in the middle of the sight glass at 6.5 P.S.I. Fuel pressure greater than 6.5

P.S.I. will cause the float level to be too high. Conversely, if the fuel pressure is significantly below 6.5 P.S.I. the float

level will be too low. For the carburetor to operate correctly the float levels must be in the middle of the sight glass.

The most accurate way to establish the correct float level is to check it while the engine is running. If the initial float

level is not visible in the sight glass then it might be necessary to re-adjust the float level before starting the engine.

(+) Ignition activated 12V source

(-) Grounded to carburetor

Timed Spark Port

Full Manifold

Vacuum

PCV

(rear of carburetor)

Timed Spark Port