Quick Fuel Technology MARINE SERIES CARBURETORS User Manual

Page 4

8. Let it idle for approximately 5 minutes. The choke should open on its own during this time and be fully open (vertical

position) after approximately 3 minutes (will vary with outside temperature).

9. If possible using a manifold vacuum gage, set the idle mixture screws to attain the highest manifold vacuum reading

at idle. It is not necessary to keep all four mixture screws at exactly the same number of turns from seated, but they

should be close to the same number of turns. Make adjustments in small increments of ¼ turn per adjustment. See

how the engine responds then adjust the mixture screws to smooth out the idle. Turning in one mixture screw could

not have any noticeable effect, if the other three mixture screws are out too far. The mixture screws should be

adjusted in conjunction with each other to achieve the proper mixture. When engineʼs RPM increases during the

adjustment process, adjust it back down to the desired rpm and continue mixture screw adjustment until the engine

RPM or vacuum drops. When the engine RPM or vacuum drop, the idle mixture is too lean and the mixture screws

will need to be backed out to the highest vacuum or RPM.

10. Turning the mixture screws in (clockwise) leans the mixture, turning the mixture screws out (counter-clockwise)

richens the mixture.

11. After you have attained the highest manifold vacuum (or best idle quality), shift the transmission into gear. This will

create a load on the engine and may change the idle characteristics. With performance camshafts with longer

duration it is often necessary to add a little more fuel because the engine is not as efficient and therefore must be

over fueled slightly to keep the engine from laboring when a load is placed on the engine such as shifting the

transmission into gear.

12. You are now ready to drive the vehicle. It may require some minor adjustments with the mixture screws and idle

speed but the engine should drive smoothly and have good throttle response.

13. Once you are satisfied with the general drivability, determine how well the engine runs while holding a steady RPM.

Generally any RPM above 2,000 RPM the carburetor is operating off the main metering system. The air fuel ratio in

this system is usually controlled by the main metering jets. If the engine surges while driving at a steady RPM on flat

ground then the mixture is probably too lean and the main jets need to be increased in size. If the engine labors and

has difficulty holding a steady speed without opening the throttle more, then the mixture is probably too rich.

Ultimately, you should look at the spark plug color after one (1) hour of runtime to help determine the general air/fuel

mixture the carburetor is delivering and the engine is operating. White plug color indicates a lean mixture, dark gray

or black indicates a rich mixture.

This carburetor has been calibrated to operate on a broad cross-section of engine combinations. While it is not

possible for a single calibration to work virtually every conceivable application it should work on most engines and it

will not be necessary to make any additional adjustments and/or tuning. Should it be necessary to alter the fuel

curve in our Hot Rod Series there is plenty of tuning capability available with changeable air bleeds, power valve

channel restrictions, and idle feed restrictions.

Adjustments & Tuning

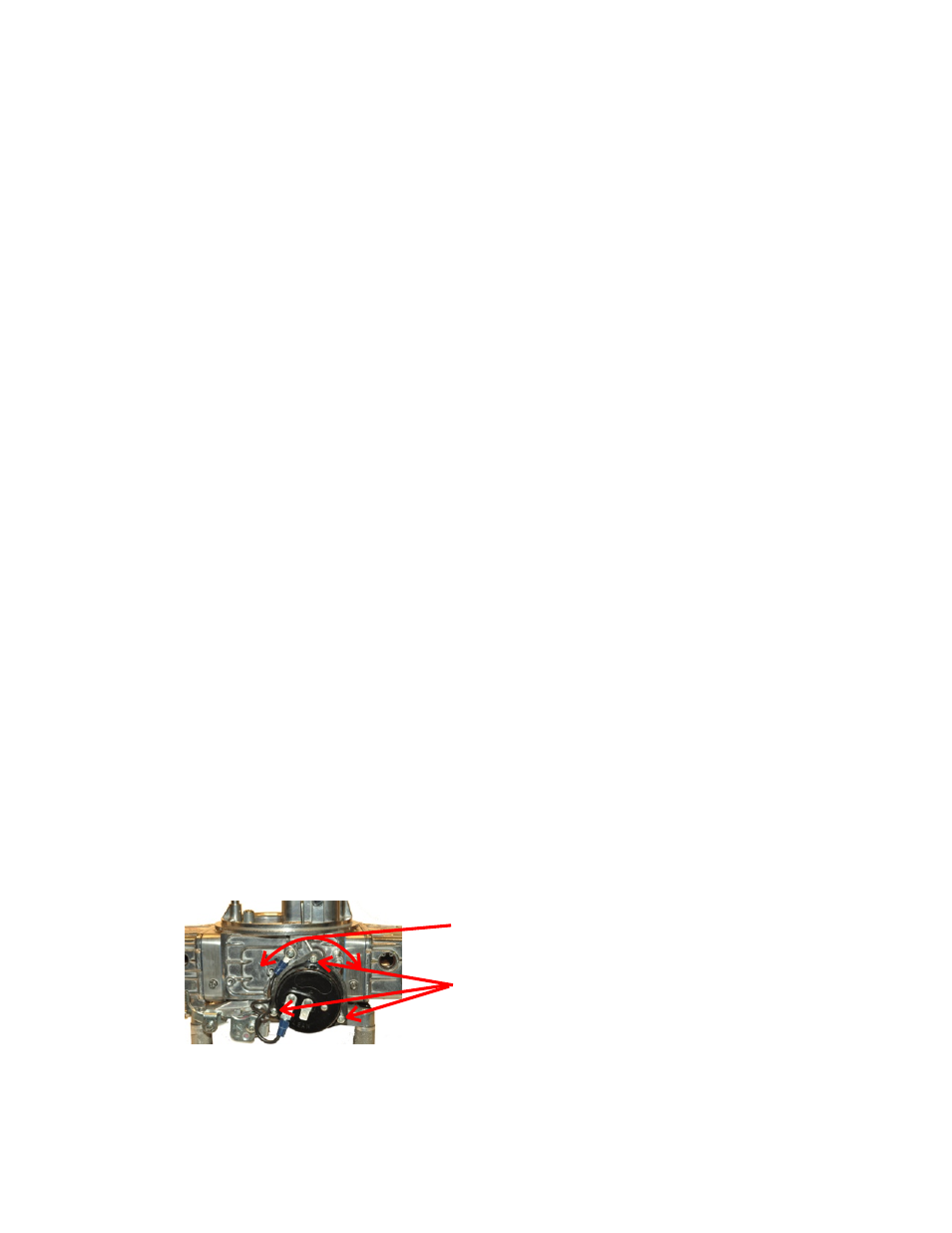

Choke Adjustments - Choke Indexing

The electric choke cap is adjustable for varying conditions and personal preference should you desire. The normal choke

setting is for the choke plate to just barely close at 72 degrees Fahrenheit. Loosening the three screws securing electric

choke spring will allow the choke cap to rotate. Rotating the choke cap clockwise reduces the choke effect (lean) whereas

rotating the choke cap counter-clockwise increases the choke effect (rich).

Clockwise Rotation Leans Choke (closes higher temperature, opens faster)

!

!

Clockwise rotation reduces temperature for choke to close and shortens the time for the choke plate to completely open. Full

clockwise rotation the choke will never close. Counter-clockwise rotation raises the temperature for the choke to close and

lengthen the time the choke plate is closed, so it will take longer for the choke plate to open to full vertical position.

Rotate to

adjust

Loosen three screws

that secure cap