JELD-WEN JII110 Interior Door Slabs User Manual

Page 2

INSTALLATION INSTRUCTIONS

for Interior Door Slabs (JII110)

2

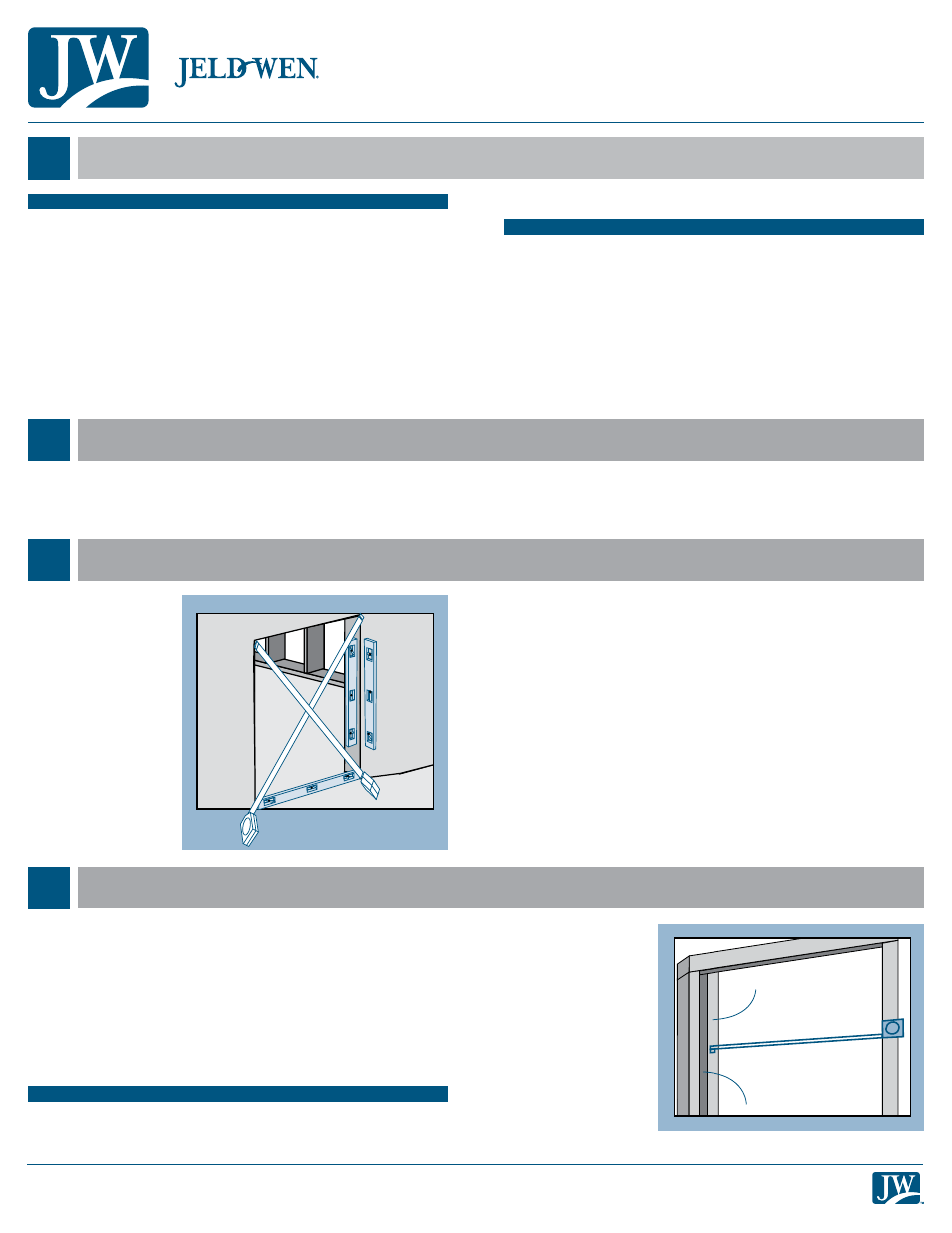

• Existing jamb should be

3/16" wider than the

slab and at least 3/8"

taller. There should

be enough distance

between the jamb

edge and the stop

to accommodate the

thickness of the slab.

• Verify the existing

jamb is square. The (A)

and (B) measurements

should be the same.

Maximum allowable

deviation from square

is 1/4".

2

INSPECT ExISTINg jAMB

a

B

d

C

e

Verify square, Level, and Plumb

• Verify the existing jamb is level and plumb (C) and (D). The maximum

allowable deviation is 1/8".

• The opening floor or sill must be flat and level (not be crowned or

sagged) (D).

• The face of the rough opening must be in a single plane (E) with less

than 1/8" twist from corner to corner.

do not install the slab unless the jamb meets the above conditions.

Professional assistance may be necessary to correct any problems before

installation.

• Remove shipping materials such as corner covers, shipping blocks

or pads.

• Inspect slab for cosmetic damage, squareness and warp

1

REMOVE PACKAgINg AND INSPECT SLAB

• Verify it is the correct product (size, color, design, handing etc.)

If any of the above conditions represent a concern, do not install the

slab. Contact the supplier for recommendations.

NEEDED mATERIALs

Note!

Follow all material manufacturers’ instructions for proper use

and compatibility.

• Hinges

• Wood screws: 3/4" minimum through hinges into the slab and frame;

For solid core, custom carved and stile and rail doors, 1 - 2 1/2"

through each of the top two hinges into framing

• Wood putty/spackle

• Lockset and template

• Finishing supplies

• Masking tape (for trimming)

needed MaTeRIaLs and TooLs

• 150-280 grit sandpaper

NEEDED TooLs

• Safety glasses

• Screwdrivers

• Pencil

• Chisel or router

• Drill with bits and hole saws

• Tape measure

• Level

• Finishing tools (paint brushes,

roller, spray equipment, masking

tape etc.)

• Circular saw (for trimming)

• Wood plane (for trimming or

beveling)

• Hammer

• Punch

INSTALL SLAB

3

ImPoRTANT:

The door slab should be finished (painted or stained) on

all six sides with an equal number of coats after all routing, trimming,

boring and touch-up has been completed and it has been properly fit

in the jamb.

Note!

If hinges are already installed on the slab, do not

remove hinges for finishing.

Failure to finish on all six sides and install into a square, level

and plumb condition could result in denial of warranty claims for

operational or performance problems. see our finishing document at

www.jeld-wen.com for finishing requirements and details.

PREPARE JAmBs AND sLAB

1. Measure the existing frame (not the stop) from floor to head and from

side to side in several places to verify the slab will fit. The frame should be

Frame

stop

3/16" wider than the

slab (1/16" clearance

on the hinge jamb and

1/8" clearance on the

strike jamb) and tall

enough (usually 1/4"

- 1/2" taller) to allow

1/8" clearance on the

head jamb and allow

the slab to operate

without rubbing on

any flooring.