Prepare the rough opening – JELD-WEN JII100 Custom Wood and Fiberglass Door Systems User Manual

Page 4

4

Prepare the Rough Opening

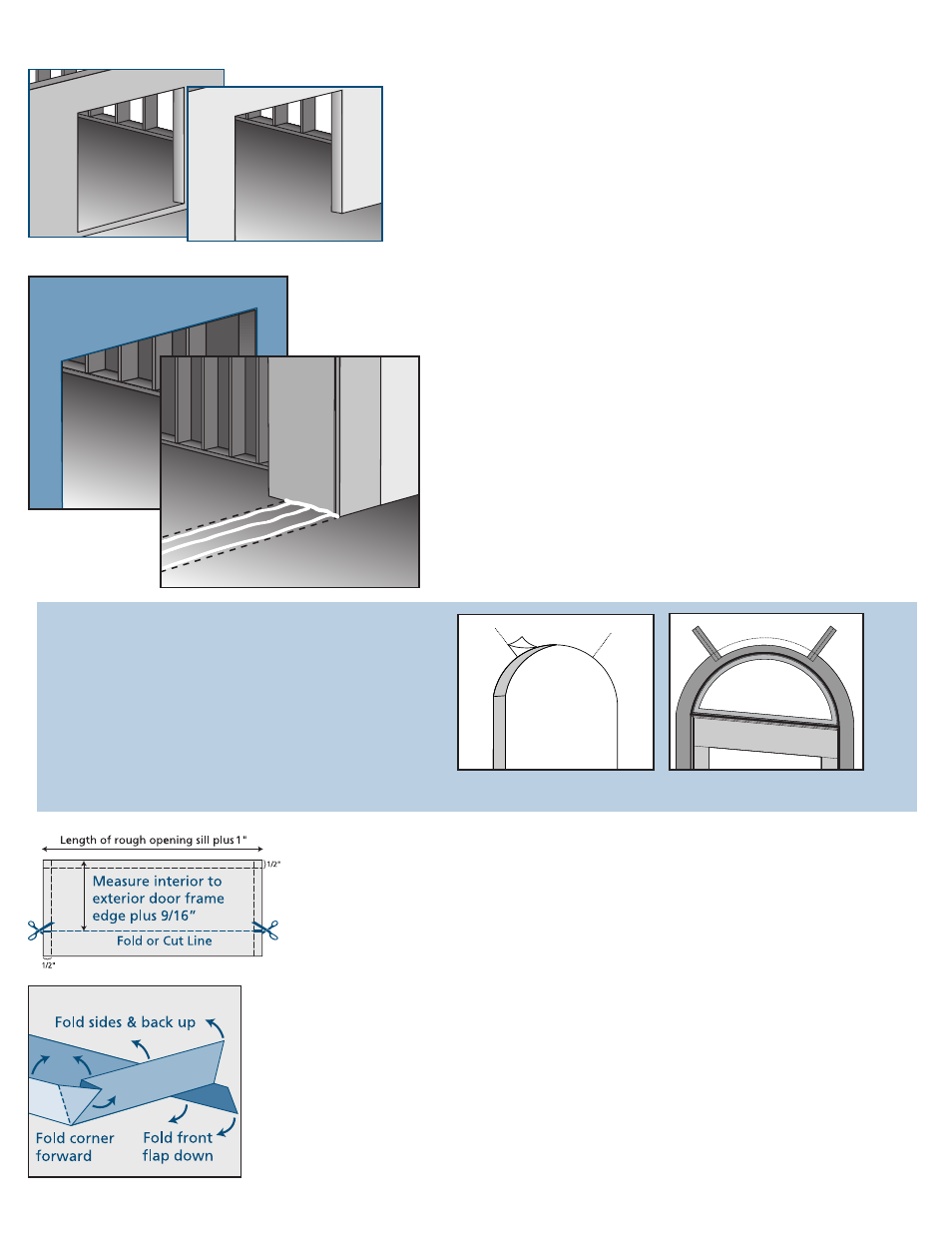

Diagram 1. Door with Curved Transom Top

• Ensure framing is sufficient around transom perimeter to allow exterior

trim to be nailed every 8" to the structure.

• Prepare rough opening in same manner as for standard door (Fig. A).

• Install transom top in same manner as for regular door except for the

following:

- Apply flashing support in short 6"-12" sections around the curved

perimeter.

- Apply conformable self-adhesive flashing to backside of flashing

support and frame.

- Apply 6" wide conformable self-adhesive flashing onto flashing

support, sheathing, and building wrap around curved edge (Fig. B).

These instructions cover two door sill conditions: the step-down landing and

the continuous slab landing. The installation methods vary slightly between the

two landing types.

Prepare the rough opening. The rough opening is to be 3/4" wider and 3/4" taller

than the net outside jamb dimension of the unit. Check floor for level

(measurements must be within 1/8"). Check walls or studs for straightness

(measurements must be within 1/4") and plumb (measurements must be

within 1/8"). Correct before installing.

For doors with a curved transom top, see diagram 1 “Door with Curved

Transom Top”. Rough opening must be level (measurements must be within

1/8") before starting; adjust as needed.

1. Clean rough opening and surrounding sheathing with a clean, dry cloth,

beginning at the top.

2. Trim building wrap flush with rough opening on header and sides; and

sill edge if door has a rise. Apply five 3/8" beads of sealant across the sill

as follows (Fig. 2):

• One 1/2" from the interior and exterior edge.

• One across the center of the sill.

• One on each side where the jambs meet the floor.

Fig. 1 Cut building

wrap

Fig. 2 Apply sealant

across sill

Step-down landing

Continuous slab landing

Fig. A Cut back building wrap

Fig. B Conformable flashing

Prepare Sill Pan

- The sill pan is a three-sided box made of plastic sheet material that sits in on

the rough opening. It is designed to catch water that infiltrates the rough opening and divert it

to the outside. This prevents damage from water collecting on the rough opening sill. Door

installations that have a step-down landing (as opposed to a door that sits directly on a

continuous slab) have slightly different sill pans.

1. Prepare the sill pan as follows (Fig. 3):

• For a 2" x 4" wall, the width of the plastic sheeting should be at least 6".

• For a 2" x 6" wall, the width of the plastic sheeting should be at least 9".

• The length should be determined by measuring the length of the rough opening plus 1".

2. Crease lines in sill pan using a straight edge as follows (Fig. 3):

• Lightly crease a line inset 1/2" along both ends and one side of the plastic sheeting.

• Measure the width of the door frame (not including the brickmold), and add 9/16".

• Take this distance and measure out from the back side; crease a line the length of the

plastic sheeting.

3. Cut 1/2" in on both ends of this line (Fig. 3).

4. Fold the sill pan as follows:

• Fold the three 1/2" sides up; use duckbill pliers to fold corners to outside of pan on short

sides (Fig. 4).

Fig. 3 Sill pan template

Fig. 4 Fold sill

pan