Materials and tools - continued, Assembly and installation instructions – JELD-WEN JII041 W-4500 Folding Door Systems User Manual

Page 3

3

NEEDED MATERIALS

Note!

Follow all material manufacturers’ instructions for proper use

and compatibility. When using flashing, spray adhesive/primer, sealant

and foam products, we recommend using the same manufacturer and

verifying compatibility.

• 3/16" masonry screws (such as Tapcon

®

) for sill installation onto

concrete. Screws must penetrate at least 1 1/2" into substrate.

• Non-compressible or water degradable shims.

• Sill pan: It is best practice to use a pre-formed, rigid, positively sloped, pvc

pan that provides continuous support. We recommend using SureSill™

Sloped Sill Pan™ , manufactured by SureSill™, Ltd. An alternative would

be a non-sloped pre-formed sill pan or one can be fabricated on site

from metal or vinyl sheet material with the proper tools.

• Sealant: We recommend OSI

®

QUAD

®

Max Sealant or equivalent. This

can be used in any application and can be painted or ordered in a

color matched product, if desired.

• Backer rod 1/8" larger than the widest portion of the gap (used in

conjunction with sealant bead).

• Polyurethane low expansion Window and Door foam: We recommend

OSI

®

QUAD

®

Foam or equivalent).

• 4", 6", or 9" (as required by local code and window configuration)

wide self-adhesive flashing: We recommend OSI

®

QUAD

®

Butyl

Flashing Tape or equivalent.

• Drip cap if required because of door location and exposure. Doors with

an adequate overhang (see our Appropriate Protection document at

www.jeld-wen.com) may not need a drip cap. In addition to sill pans,

SureSill™ also offers types of head flashing.

FOR INSTALLATIONS INTO A BUCK:

• Liquid applied flashing (Protecto Wrap LWM 200 or equivalent).

NEEDED TOOLS

• Tape measure

• Utility knife

• Level (3' and 6' recommended)

• J-roller

• Caulking gun

• Vacuum for removing debris

from sill track

• Drill and Impact driver (optional)

with bits

• Spade bit (3/4" for center pivot)

• Denatured alcohol (for installing

clad astragal covers)

• Screwdrivers (small) for sill carrier

adjustment

• 14 mm open end wrench (panel

adjustment only)

• Step Ladder (2)

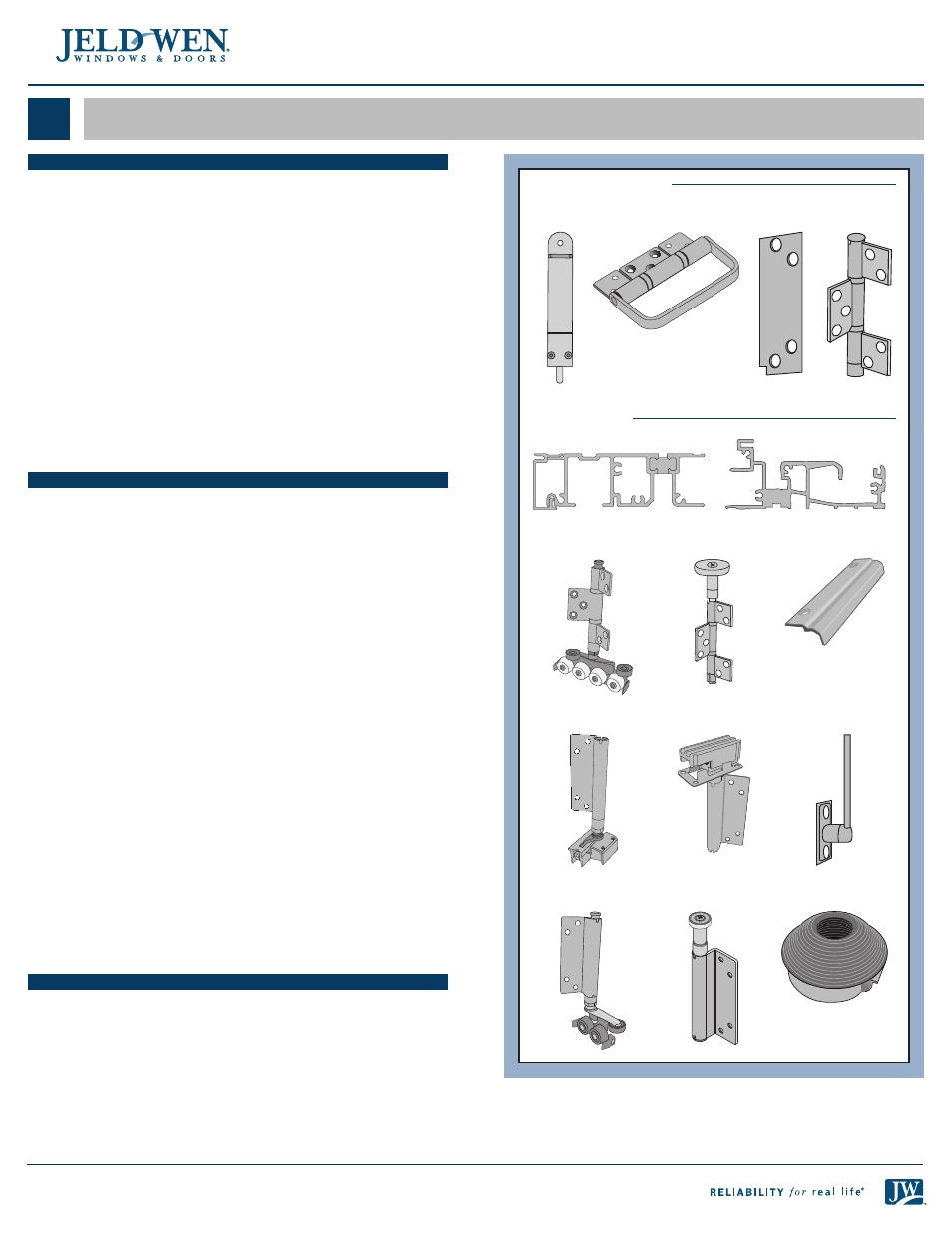

INCLUDED PARTS - CONTINUED

ATTACHED TO PANELS

• Hinge set (may include handle) - #10 x 1.5" screws

• Flush bolt(s)

• Multipoint locking hardware strikes

• Astragal

SHIPPED LOOSE

• Head track

• Sill track

• Top and bottom intermediate

(4-wheel) carrier guide set with

hinge leaf (dependent upon

configuration)

• Top and bottom intermediate

(2-wheel) carrier with hinge leaf

(dependent upon configuration)

• Upper wall pivot - #6 x 1" screws

• Lower wall pivot - #6 x 1" screws

• Center wall pivot and housing

with screws - #10 x 1"

• Sill track seal

• Handle set (optional and/or

dependent upon configuration)

• Lower pivot cover and screws -

#8 x 3/8"

• Clad astragal cover (2) -

(dependent upon configuration)

Flush

Bolt

Center Wall Pivot

with Housing

Hinge

Set

Top Intermediate

Guide

Top

Directional Guide

Lower

Pivot Cover

Intermediate Carrier Set

(Four Wheel)

Directional Carrier Set

(Two Wheel)

Lower

Wall Pivot

Upper

Wall Pivot

ATTACHED TO PANELS

SHIPPED LOOSE

Head Track

Sill Track

Seal

MATERIALS AND TOOLS - CONTINUED

Handle

Center Pivot

Hinge Leaf

Sill Track

ASSEMBLY AND INSTALLATION INSTRUCTIONS

for W-4500 Folding Door Systems (JII041)