Bg-pure system configuration, Table 2, Source water supply profile – Water Inc WI-BG-PURE User Manual

Page 4: Chemical parameters, Conditions for use, Options and accessories, Product water faucets, Certified contaminant reduction performance

II

CERTIFIED CONTAMINANT REDUCTION PERFORMANCE

The following Body Glove BG-PURE Reverse Osmosis System conforms to NSF/ANSI 58 for the specific performance claims as verified and

substantiated by test data.

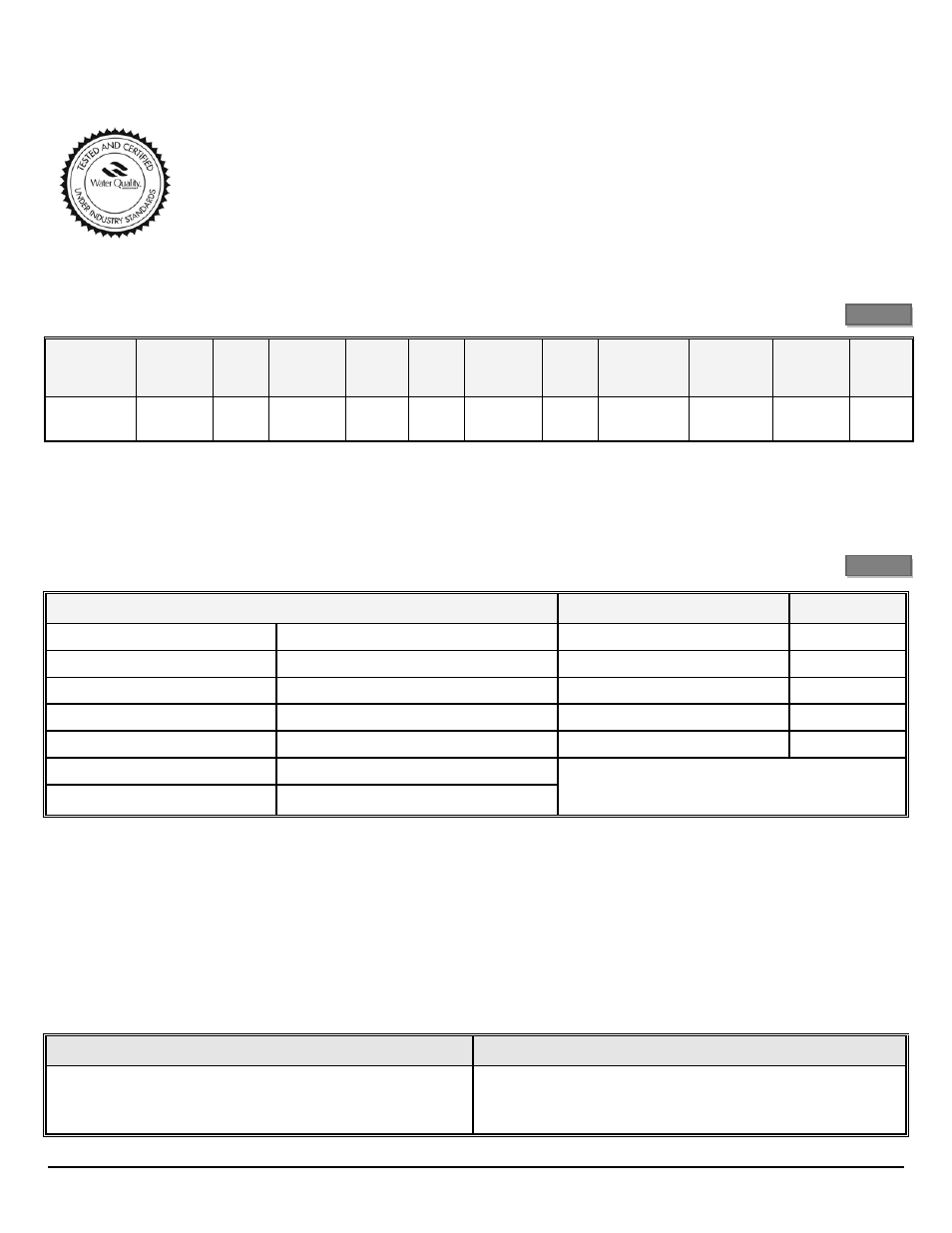

BG-PURE SYSTEM CONFIGURATION

Table 1

Model

Description

Storage

Tank

# of

Vessels

Storage

Tank

Capacity

Liters (gal)

Vessel

1

Vessel

2

Vessel

3

Vessel

4

Daily

Production

Rate

(2)

L/day

(G/day)

Efficiency

Rating

(3)

%

Recovery

Rating

(4)

%

Monitor

(6)

4VTFC25G-PB

Plastic/Metal

4

7.19 (1.9)

Sediment

Filter

Carbon

Filter

TFC

(1)

Membrane

Carbon

Filter

29.1 (7.7)

8.2

18

Smartap®

Push

Button

The manufacturer tested higher efficiency and recovery ratings using the 25 GPD TFC membranes with the Body Glove

BG-Pure. Stringent NSF/ANSI 58 testing criteria reported lower efficiency and recovery ratings, representing the worst

case tested scenarios. Under surrogate testing, using a storage tank with backpressure, the TDS reduction efficiency

percentage averaged 95% and the recovery rating percentage averaged 28.5% based on manufacturer test data.

CONDITIONS FOR USE

Table 2

Source Water Supply Profile

Chemical Parameters

Max mg/L

Community/Private

Chlorinated/Non-Chlorinated

Hardness (CaCO

3

)

<350 (20 gpg)

Feed Water Pressure

(5)

242-690 kPa (35-100 psi)

Iron (Fe )

<0.1

Temperature

4°-38° C (40°-100° F)

Manganese (Mn)

<0.05

pH Range

3.0 - 11.0

Hydrogen Sulfide (H

2

S )

0.00

Maximum TDS Level

2000 mg/L

Residual Chlorine (Cl

2

)

<2.0

Turbidity**

<1.0 NTU

** Nephelometric Turbidity Unit

*** Silt Density Index: Value stated in SDI units.

Maximum SDI***

<4.0

NOTES:

1. TFC refers to reverse osmosis membranes constructed from a THIN FILM COMPOSITE.

2. The daily production rate is the volume of product water produced by the system per day and is determined by testing in accordance with the procedure

outlined in NSF/ANSI Standard 58.

3. System’s Efficiency rating as verified by testing in accordance with NSF/ANSI standard 58. Efficiency rating means the percentage of the influent water to

the system that is available to the user as reverse osmosis treated water under operating conditions that approximate typical daily usage.

4. System’s Recovery rating as verified by testing in accordance with NSF/ANSI Standard 58. System’s Recovery rating means the percentage of the influent

water to the membrane portion of the system that is available to the user as reverse osmosis treated water when the system is operated without a storage

tank or when the storage tank is bypassed.

5. PRESSURE REGULATOR IS RECOMMENDED FOR FEED WATER PRESSURES EXCEEDING 552 kPa (80 psi).

6. SMARTAP® PUSH BUTTON MONITOR. Indicator lights located on the module cover report system status.

OPTIONS AND ACCESSORIES

PRODUCT WATER FAUCETS

BOOSTER PUMP

Faucets will be supplied as Air Gap.

A booster pump may be used if system pressure is below 242 kPa (35 psi).

Pump should be placed near RO Module and installed in feed water line just

before it enters Module.

Model 4VTFC25G-PB is tested and certified by WQA against NSF/ANSI 58 for the reduction of TDS