UEi Test Instruments C127OILKIT User Manual

Page 17

vented

outside

vented

inside

vented

outside

vented

inside

i

NformatioN

oN

e

xCeSS

a

ir

• Excess Air

- Theoretically perfect combustion would have the exact amount of O2 to combine with all of the fuel,

resulting in no excess air.

• If perfect combustion were possible, there would be 0% excess air

• Because perfect combustion is not possible, you will always have some excess air

• Too high excess air will reduce the time fuel and oxygen are together in the combustion

chamber, and lower the temperature – two of the T’s of combustion

• Too little excess air, and all of the fuel will not be burnt

- Carbon will form CO instead of CO2

• Typical Excess Air Level

O2% (measured)

Excess Air %

Natural gas

3%

16.7%

Light Oil

5%

31%

Coal

8%

62%

Excess Air is also one method that can be used to determine heat exchanger integrity

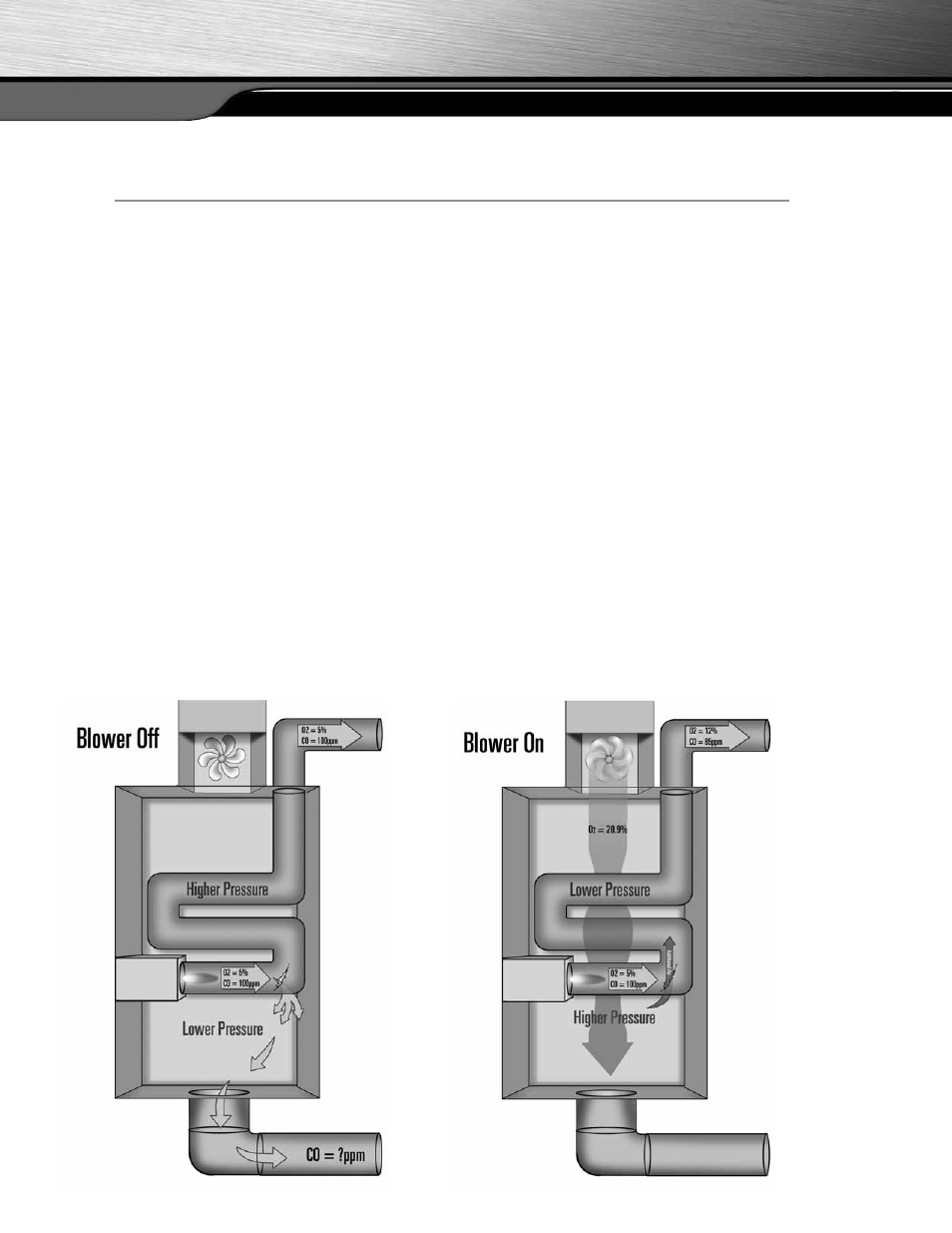

• Before the blower starts the pressure is higher on the combustion side of exchange (see figure 5)

– Small amounts of CO may leak into the living space side

– Flue gas measurements will be stabilizing as the combustion chamber heats up.

• After the blower starts the pressure on the primary side will be higher (See figure 6)

– Blower forcing air through the heat system

– Fresh air may now enter the flue through the breach in the heat exchange

• Observe the flue gas levels and check the following;

- Excess Air, 02 level and CO in ppm for drastic changes.

figure 6

figure 5

16

17