Inspection / maintenance – NORD Drivesystems B1901 User Manual

Page 5

- 5 -

Operating and assembly instructions spring-loaded brake FDW – ATEX

Inspection / maintenance

Safety measures and actions

De-energise motor and brake and protect them from an

accidental reclosure.

The brake must not be opened for inspection in an explosive atmosphere.

Inspection:

Turn out the radially arranged screw plug (item 12),

measure the existing air gap (feeler gauge 5 mm wide) and compare

it with table 2 - below.

Screw down the screw plug (item 12) again – pay attention to O-ring -

and secure it with locking paint.

To be noted!

When the max. air gap is reached, the brake rotor has to be exchanged!

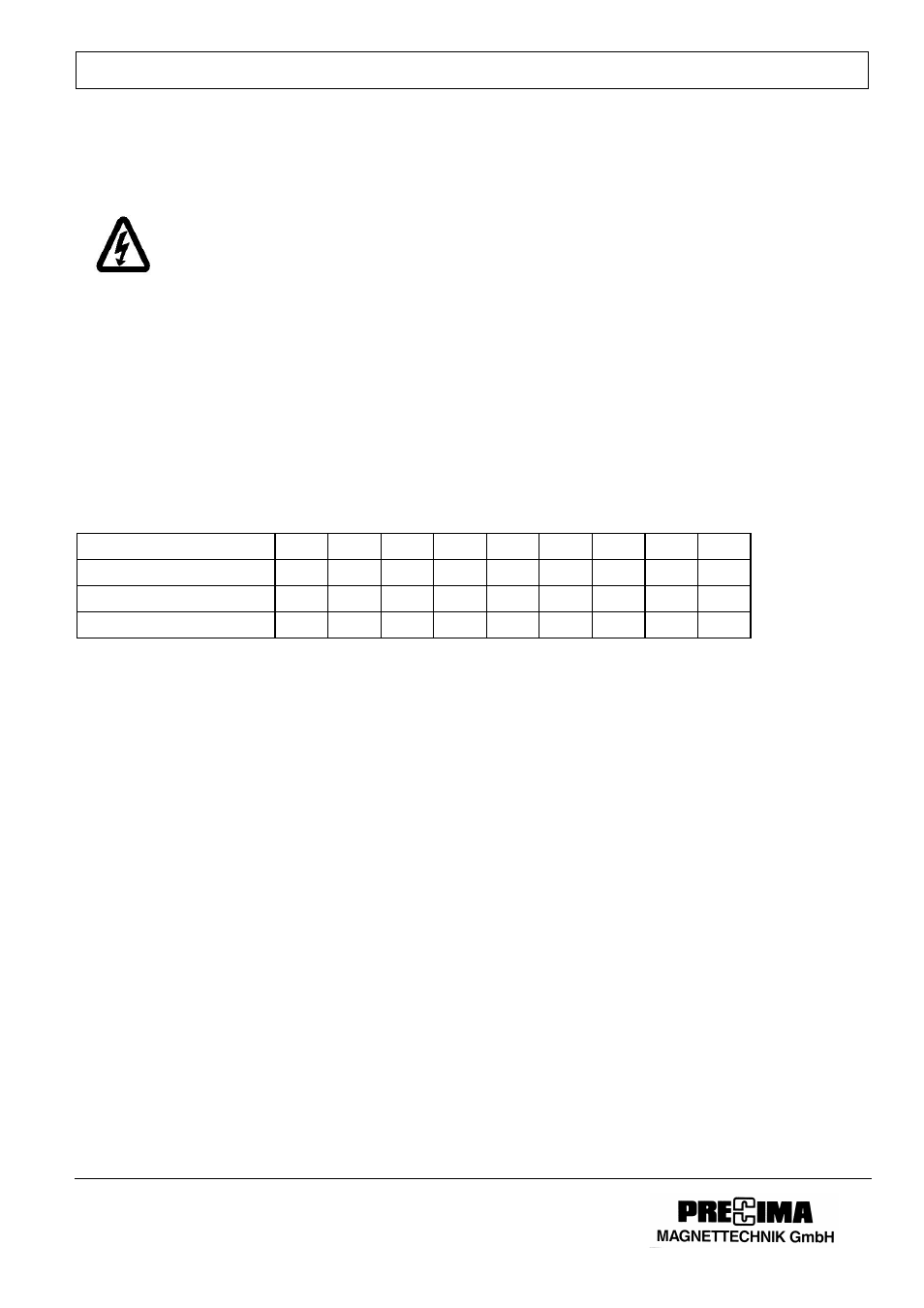

Table 2

FDW

08

10

13

15

17

20

23

26

30

a

Nom

+0,1

0,2

0,2

0,3

0,3

0,3

0,4

0,4

0,5

0,5

a

max

0,5

0,6

0,8

0,8

0,8

0,9

0,9

1,0

1,0

Rotor size (new)

7,5

8,5

10,3 12,5 14,5

16

18

20

20

Dimensions indicated in mm

Control PTC thermistor: Resistance (at 20°C) < 100 Ohm

To be noted: Cable diameter 3,7 mm

The working air gap cannot be readjusted.

When assembling the controlled brake, the Cu-washers under the

fastening screws have to be replaced.

Inspection intervals:

When using the spring-loaded brakes:

as a working brake

at least every 3000 operating hours, refer to additional information

as a holding brake

depending on operating conditions and load every 2 to 3 years

with emergency-stop properties

refer to additional information