NORD Drivesystems B1901 User Manual

Page 4

- 4 -

Operating and assembly instructions spring-loaded brake FDW – ATEX

Electrical connection of the brakes

The coil voltage (VDC) is visible on the motor type plate and has also been embossed into the

magnet housing.

Operating voltage 90 % to 110 % of the nominal voltage of the spring-loaded brake.

Technical data:

Table 1

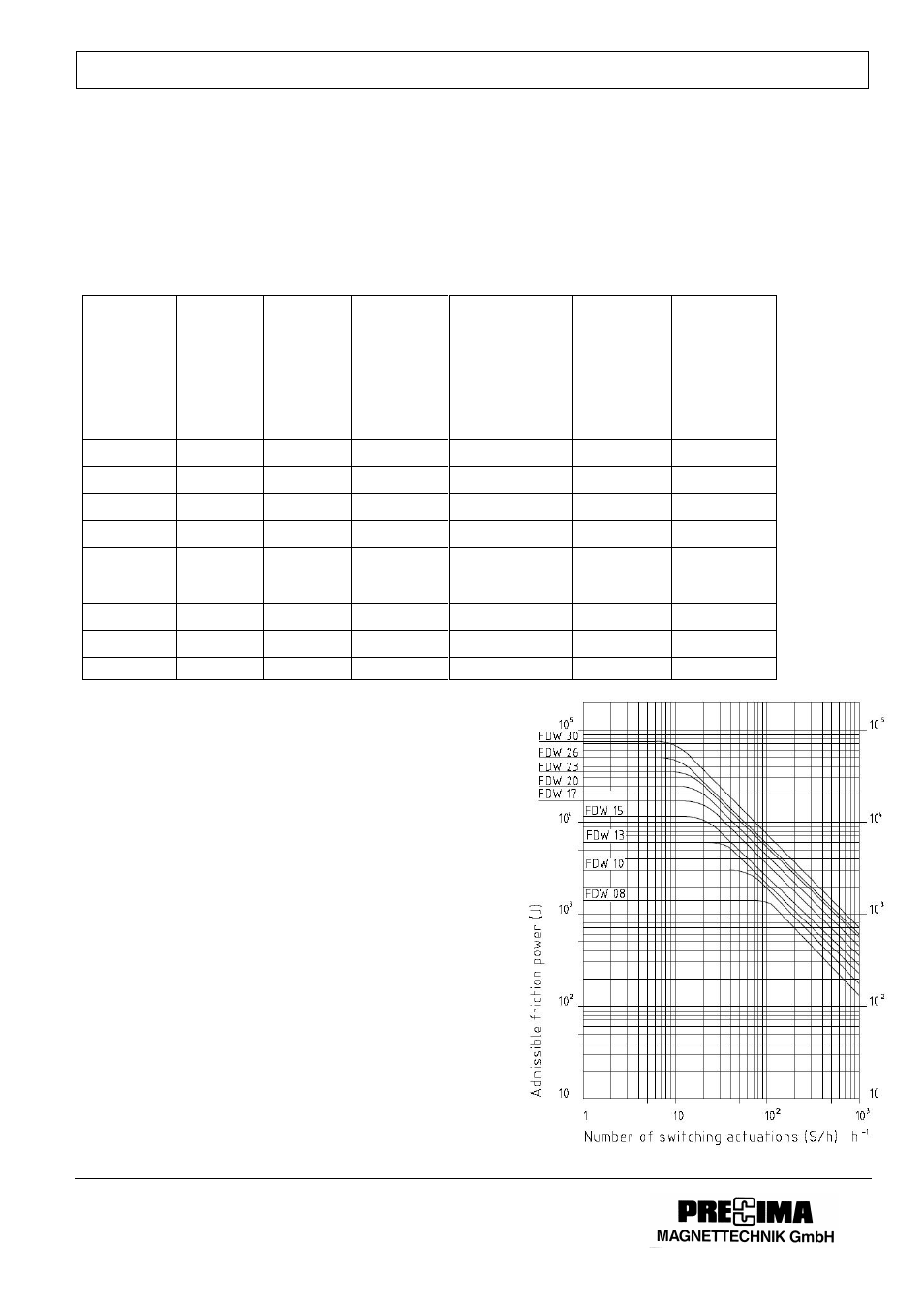

Since wear and tear of the brake depends on

several factors of influence such as operating

frequency, switching energy per switching

operation, braking torque and climatic conditions

the values indicated with regard to max. switching

energy can only be guidance values.

W

Rmax

(max. switching energy) is the switching

energy which must not be exceeded with braking

operations from max. > 1500 min

-1

.

Braking operations from a speed of > 1500 min

-1

considerably reduce the max. admissible switching

energy per switching operation. In this case, please

contact the manufacturers for advice.

The maximum switching power P

max

is the switching

energy W which is achievable every hour.

If during operation both P

max

and W

max

are

simultaneously nearly reached, the diagram

(W

max

depending on the hourly switching time)

shown in the operating instructions has to be used.

Brakes

size

M

bN

Standard

(Nm)

P

Standard

(W)

W

Rmax

max.

friction

energy

per

braking

(J)

P

R

max.

admissible

friction

power

(J/h)

Fastening

screws

Tightening

moment of

the screws

M

A

(Nm)

FDW 08

5

33

1,5x10

3

140x10

3

3 x M4

3

FDW 10

10

42

3,0x10

3

180x10

3

3 x M5

6

FDW 13

20

50

6x10

3

230x10

3

3 x M6

10

FDW 15

40

63

12x10

3

280x10

3

3 x M6

10

FDW 17

60

75

17x10

3

360x10

3

3 x M8

25

FDW 20

100

96

25x10³

450x10³

3 x M8

25

FDW 23

150

114

37x10³

540x10³

3 x M8

25

FDW 26

250

150

52x10³

630x10³

3 x M10

50

FDW 30

400

210

75x10³

720x10³

6 x M10

50