NORD Drivesystems B1901 User Manual

Page 3

- 3 -

Operating and assembly instructions spring-loaded brake FDW – ATEX

Design:

Spring-loaded brakes type FDW ATEX are designed as enclosed brakes IP 65.

The spring-loaded brakes are delivered with a firmly adjusted braking torque and air gap.

Mode of functioning:

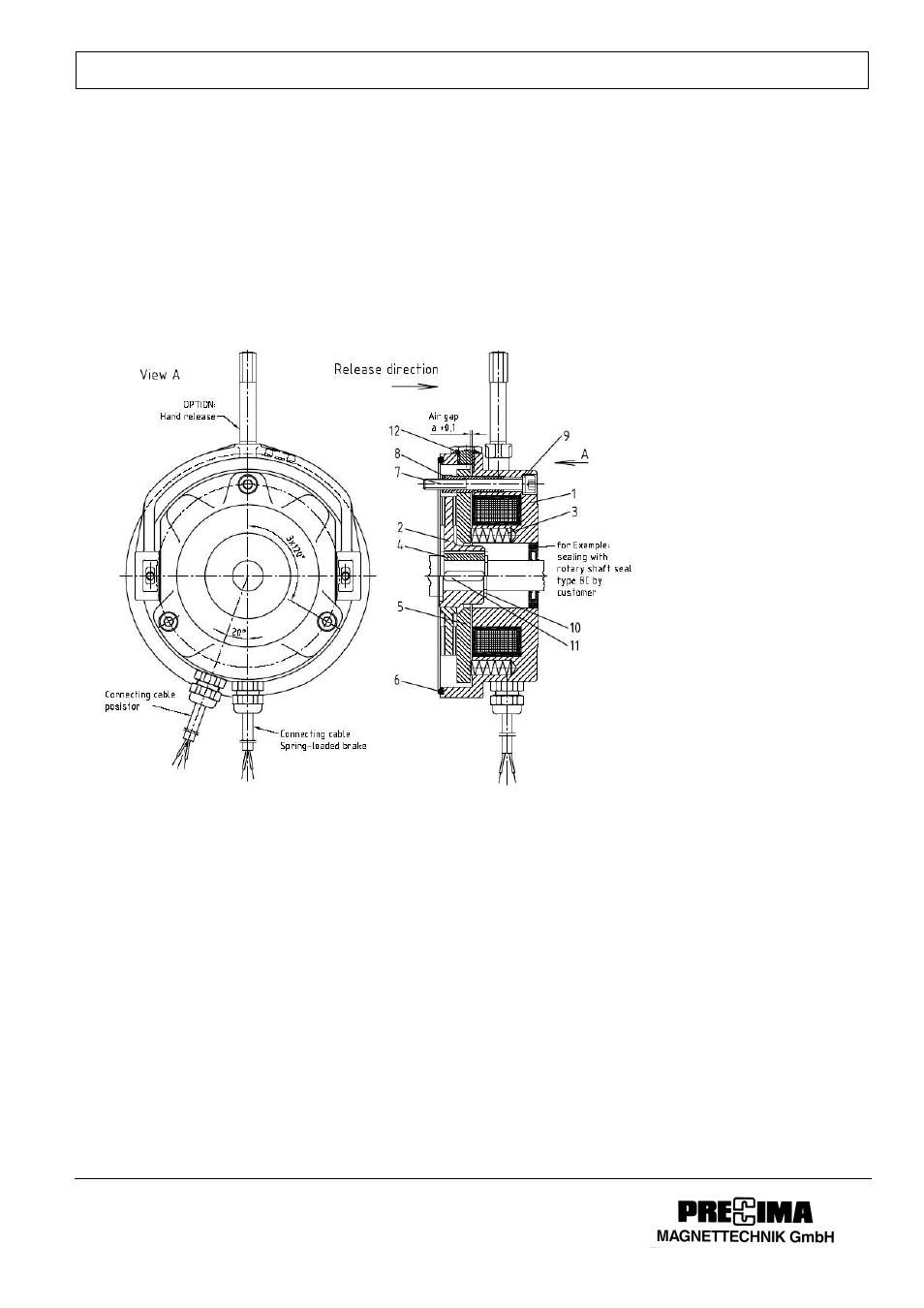

By means of applying a direct voltage to the excitation winding in the magnet body (item 1) a

magnetic force is created which will act upon the armature plate (item 5). Via the air gap “a“,

this will be drawn towards the magnet body (item 1) against the compressive force of the spring

(item 3).

The braking rotor (item 2) will be released and the braking torque cancelled.

Sketch:

1 Magnet housing

2 Rotor

3 Spring

4 Hub

5 Armature plate

6 O-ring

7 Fastening screw

8 Banjo bolt

9 Cu-washer

10 Circlip

11 Key

12 Screw plug

Assembly:

Assembly conditions:

Rotor and brake surfaces must be free from oil and grease.

A suitable counter friction surface (steel or GG Rz 6,3) must be available.

The hub is to be brought into such a position that there is a coverage rotor/hub.

Assembly:

The spring-loaded brakes will be delivered in a preassembled condition.

Insert circlip ring (item 10) into the keyway

Insert key (item 11) into the motor shaft

Push hub (item 4) onto the shaft and lock it by means of circlip (item 10)

Push rotor (item 2) onto hub (item 4) – you must be able to easily move the rotor

on the hub.

Tighten brake body with 3 fastening screws – for tightening torque refer to table in

technical data.

The air gap of the brake is given by constructional dimensions.