The equipment – Kaman KDM-8200 User Manual

Page 21

21

Kaman Precision Products

The Equipment

Sensor

Sensor mounting is critical to the operation and accuracy of the measuring system.

Mounting

Fixturing must be stable through changing environmental conditions, such as

temperature variation or vibration. The impact of these changes is relative: a 0.00001"

change is negligible when only 0.001" accuracy is required.

Conductive

Simply keep in mind that fixturing must be capable of maintaining the accuracy required

vs.

by your application. If you do need to mount the sensor, note that the sensor’s field may

Nonconductive interact with the fixture and change your system calibration. Shielded sensors will

interact less with a conductive fixture than unshielded sensors. When using a conductive

fixture, it is important that you calibrate your sensor channels with the sensor in place in

the application fixture, or in a fixture that duplicates the actual loading effects of the

application fixture. Loading is the effect of conductive material (other than the target)

that is positioned within 3 times the diameter of the sensor and is a permanent part of the

measuring environment.

Simulated

Install the sensor in the application fixture exactly as it was in the simulated one. When moving

vs.

from the simulated fixture to the application fixture, deviations may occur through changes in

Application

loading or in mechanical position. To ensure maximum accuracy, calibrate the sensor in the

Fixture

actual application fixture whenever possible.

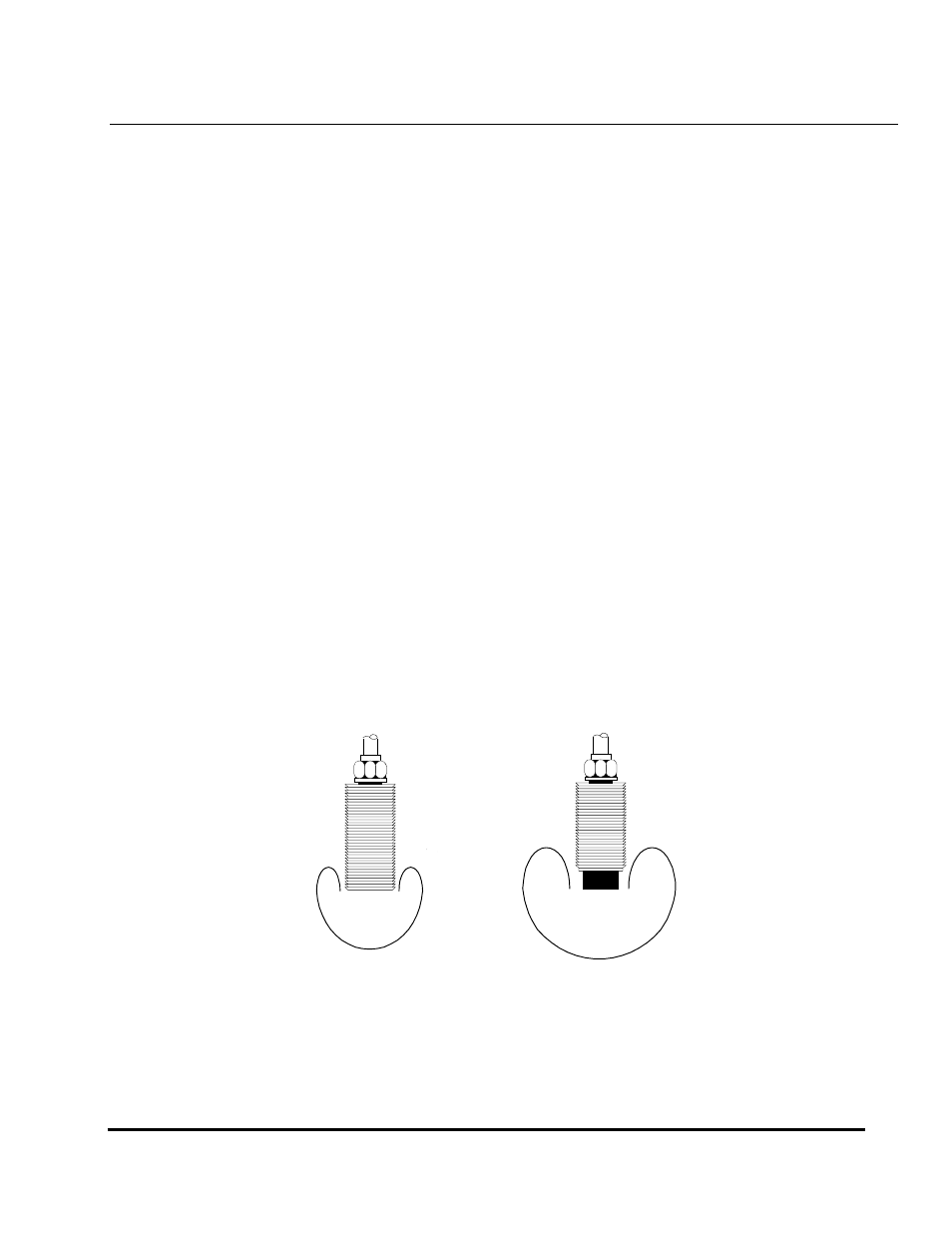

Conductive

Keep in mind the following general rule: Mount unshielded sensors 2.5 to 3 times their

Materials

diameter away from conductive materials; for shielded sensors use a factor of 1.5 to 2 times

in the

diameter.

Measuring

Area

SENSOR

VIEWING

AREA

SHIELDED SENSOR

1.5 TO 2X DIAMETER

UNSHIELDED SENSOR

2.5 TO 3X DIAMETER

SENSOR

VIEWING

AREA