Installation – Dwyer LIN-E-AIRE® User Manual

Page 5

5

ACTUATOR MATERIALS

Frame: Cast Iron, Baked Enamel Finish.

Diaphragm Case: Steel, Baked Enamel Finish.

Diaphragm: Buna-N-rubber, Nylon reinforced.

Range Spring: Plated spring steel.

Range Spring Seat: Plated steel.

Adjusting Screw: Plated cold rolled steel.

Push Rod: Plated steel.

AMBIENT TEMPERATURE LIMITS

-32 to 150°F (-36 to 66°C).

MAXIMUM ACTUATOR AIR PRESSURE

Refer to Table 3.

AIR CONNECTION: 1/4˝ female NPT.

MAXIMUM STROKE

Refer to Table 3.

2. INSTALLATION

2.1 Mounting - The Lin-E-Aire

®

Valve Actuator is normally fur-

nished mounted on a valve body. Follow the valve body instruc-

tions when installing the control valve in the pipeline.

Clearance should be left above and below the control valve to

permit removal of actuator and valve plug. Removal clearance

dimensions are specified in the control valve instructions, as well

as installation instructions. The actuator will sometimes be

shipped alone for field mounting on a valve body. Mount actuator

as outlined in the control valve instructions.

2.2 Pneumatic Connections - Connect the input pressure to

the 1/4˝ female NPT port on the top of an air-to-lower actuator or

under the diaphragm casing on an air-to-raise actuator, Figure 3

or 4. Either pipe or tubing may be used for the air line. The input

pressure must not exceed the limits listed under the specifica-

tions.

When there is a long distance between the actuator and the con-

trol device which produces the input pressure, or when a large

actuator size is required, there may be excessive transmission lag

in the control signal. A W.E. Anderson Valve Positioner, Catalog

Number 100N or 165, can be used to reduce the lag. If a valve

positioner is included with the actuator, connections between the

positioner and actuator are made at the factory. Refer to the valve

positioner instructions for additional connection information.

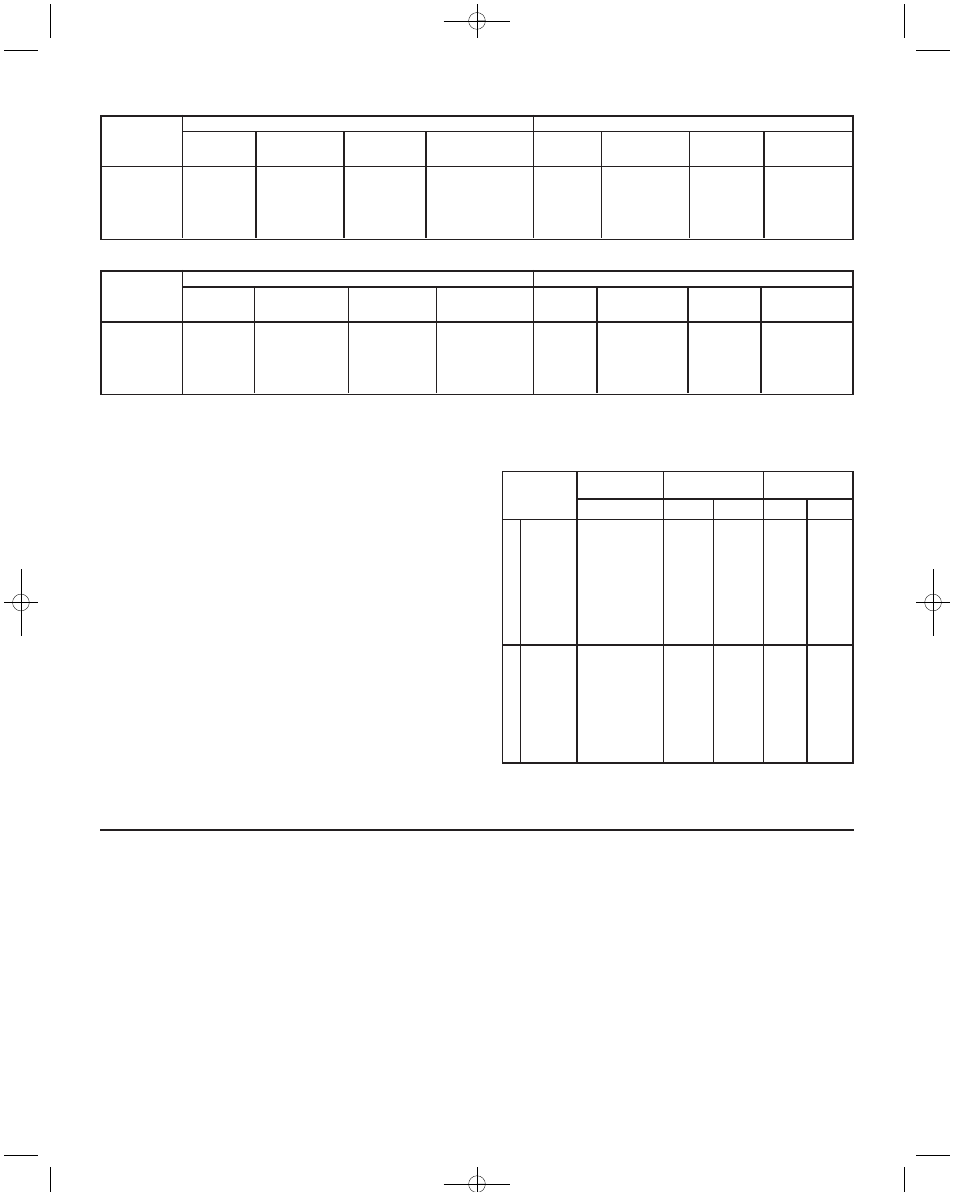

Boss

Dia.

1-1/2˝

1-15/16˝

2-1/8˝

2-13/16˝

2-13/16˝

Term.

No.

220

222

240

242

244

Part

No.

15S620

15S622

15S640

15S642

15S644

No. of

Bolts

10

12

12

12

18

Effective

Area

20 sq. in.

45 sq. in.

20 sq. in.

45 sq. in.

80 sq. in.

Term

No.

221

223

241

243

-

Part

No.

15S621

15S623

15S641

15S643

-

No. of

Bolts

12

18

12

18

-

Effective

Area

45 sq. in.

80 sq. in.

45 sq. in.

80 sq. in.

-

Standard Actuator

Senior Actuator

Table 1. Air-to-Lower Actuator

Boss

Dia.

1-1/2˝

1-15/16˝

2-1/8˝

2-13/16˝

2-13/16˝

Term.

No.

230

-

250

252

254

Part

No.

15S630

-

15S650

15S652

15S654

No. of

Bolts

10

-

10

12

18

Effective

Area

20 sq. in.

-

20 sq. in.

45 sq. in.

80 sq. in.

Term

No.

231

233

251

253

-

Part

No.

15S631

15S633

15S651

15S653

-

No. of

Bolts

12

18

12

18

-

Effective

Area

45 sq. in.

80 sq. in.

45 sq. in.

80 sq. in.

-

Standard Actuator

Senior Actuator

Table 2. Air-to-Raise Actuator

Termination

Number

Part No.

Max. Air Supply

Pressure

Max. Stroke

Inches

mm

psig

kPa

Standard

Air

-to-Lower

Air

-to-Raise

220

240

221

241

222

242

223

243

244

230

250

231

233

251

252

253

254

15S620

15S640

15S621

15S641

15S622

15S642

15S623

15S643

15S644

15S630

15S650

15S631

15S633

15S651

15S652

15S653

15S654

100

100

50

50

100

100

50

50

70

100

100

50

50

50

100

50

70

700

700

350

350

700

700

350

350

480

700

700

350

350

350

700

350

480

1

1

1

1

1-1/2

1-1/2

1-1/2

1-1/2

2-1/4

1

1

1

1-1/2

1

1-1/2

1-1/2

2-1/4

25.4

25.4

25.4

25.4

38.1

38.1

38.1

38.1

57.2

25.4

25.4

25.4

38.1

25.4

38.1

38.1

57.2

Table 3. Maximum Air Supply Pressure and Maximum Stroke

1.3 Specifications

IB-5A103:IB-5A103 1/29/10 11:37 AM Page 5