Introduction – Dwyer LIN-E-AIRE® User Manual

Page 3

3

1. INTRODUCTION

1.1 DESCRIPTION

The Lin-E-Aire

®

Valve Actuators are used for automatic opera-

tion of the control valve. The opening, closing or throttling of the

valve plug in the valve body is accomplished by varying the air

pressure to the diaphragm in the actuator. This pressure is trans-

mitted from a control device, which may be controlling pressure,

liquid level, temperature or flow.

Two types of actuators are used for process control, the choice

of either depends upon the valve action desired in case of air

supply failure. There are two types

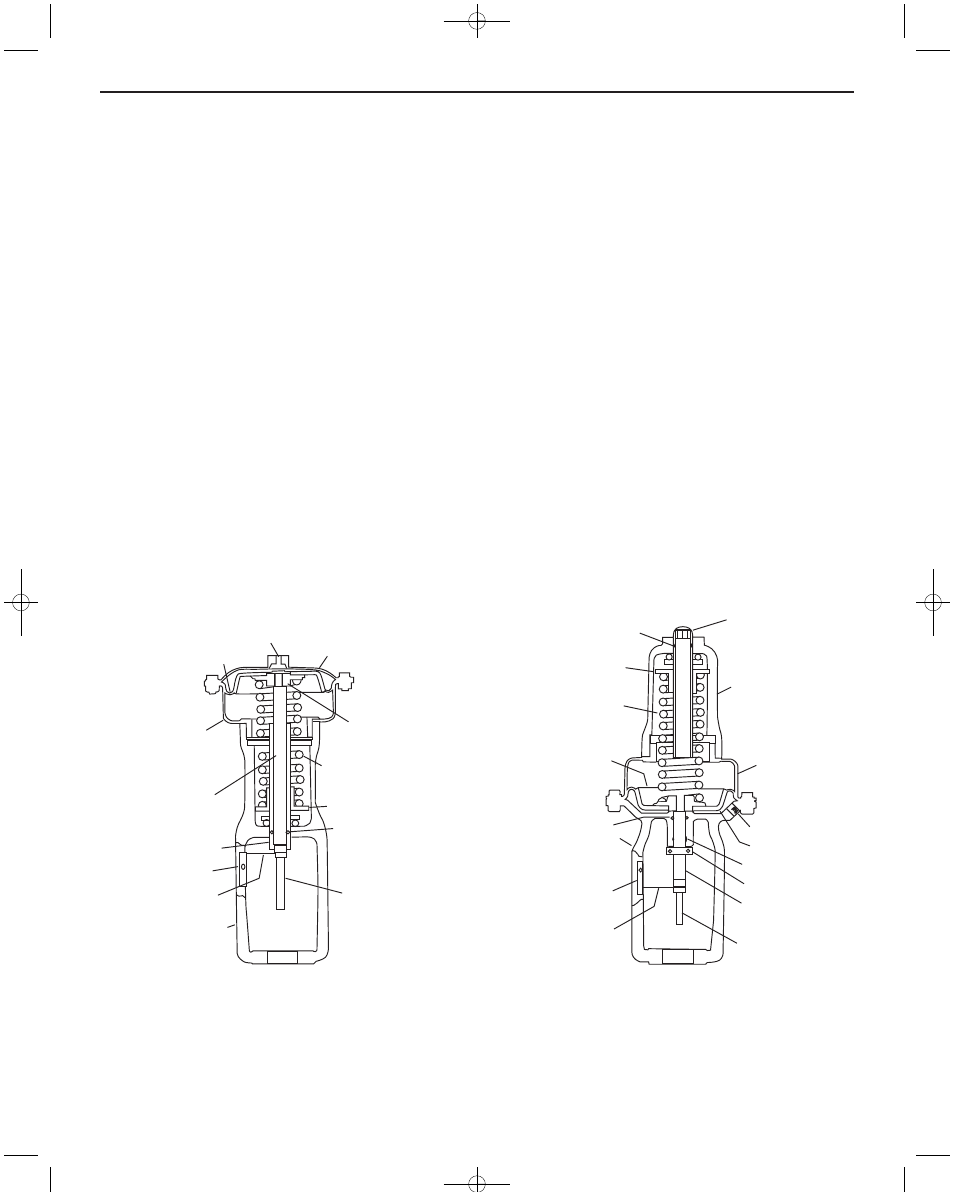

Air-to-Lower - Termination Nos. 220 thru 223, 240 thru 244,

Figure 1. In this type of actuator, air pressure moves the push rod

downward compressing the spring. In the event of air failure, the

push rod moves to its extreme upward position.

Air-to-Raise - Termination Nos. 230, 231, 233, 250 thru 254,

Figure 2. In this type of actuator, air pressure moves the push rod

upward compressing the spring. In the event of air failure, the

push rod moves to its extreme downward position.

Thus, by selection of actuator and control valve plug action,

either push-to-close or push-to-open, the control valve will either

open or close on failure of air pressure to diaphragm.

The spring and diaphragm are completely enclosed to protect

them from dust, dirt and other foreign matter. Spring adjustments

are made with a ball bearing spring adjustment sleeve.

Diaphragm and spring assembly may easily be removed for

replacement or substitution.

The construction and operating range are listed on the data plate

mounted on actuator. Actuator size and spring are selected to

meet the requirements of the application. In service the actuator

should create full travel of the valve plug when the pressure range

indicated on data plate is applied. This pressure range is most

generally 3 to 15 psi (20 to 100 kPa), but other ranges are avail-

able.

For precise control of valve plug position or where two valves are

to be operated in sequence by one control device, a W.E.

Anderson valve positioner, Catalog Number 100N or 165, is rec-

ommended.

O-Ring

Spring Seat

Range Spring

Push Plate

Assembly

Upper Diaphragm

Casing

1/4˝ NPT

Input Connection

Diaphragm

Lower Diaphragm

Casing

Push Rod

Range Spring

Adjusting Screw

Travel Indicator

Plate

Travel Indicator

Yoke

Valve Stem

Figure 1. Air-to-Lower Actuator

Range Spring

Adjusting Screw

Spring Casing

Diaphragm

Casing

1/4˝ NPT

Input Conn.

Diaphragm

O-Ring

Travel Stop

Collar

Push Rod

Valve Stem

Travel Indicator

Travel Indicator

Plate

Yoke

V-Packing

Push Plate

Range Spring

Spring Seat

O-Ring

Figure 2. Air-to-Raise Actuator

IB-5A103:IB-5A103 1/29/10 11:37 AM Page 3