Dwyer MTL7787 User Manual

Page 12

8

INM7700-6 Jan 2010

5.3.2

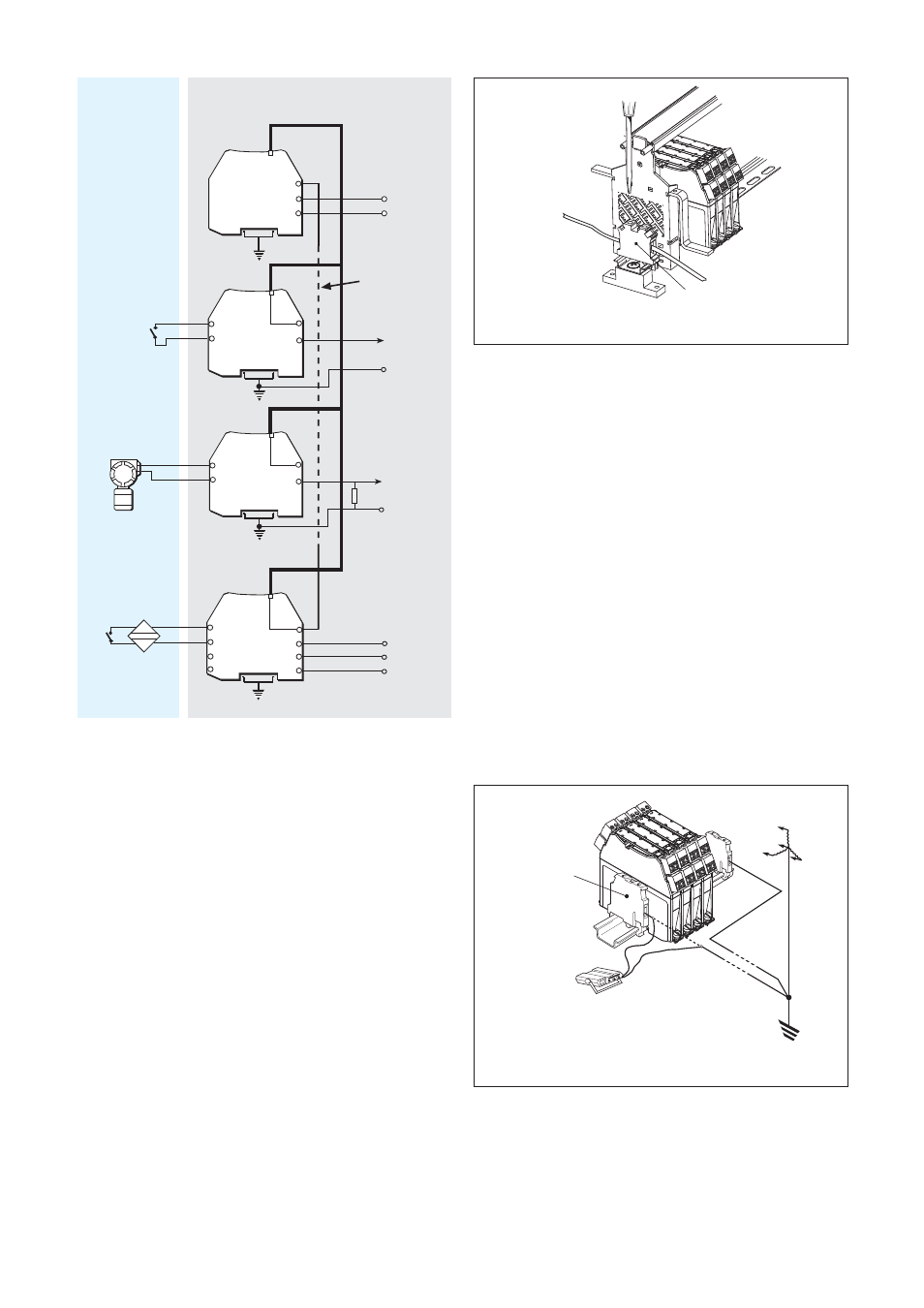

Earthing an installation

See figure 15. Connections from the DIN-rail to a suitable plant earth

are made from ETL7000 earth terminals. These clip onto the DIN-rail

as described in section 4.3.3 to make the vital earth connection with

the rail and the barriers. They are provided with two screw-clamp

terminals, to one of which a copper conductor to plant earth should

be connected. This should have a resistance no greater than 1

Ω

though to increase safety and reduce interference, a resistance as

close to 0.1

Ω as possible is preferable. The cross-sectional area of

the conductor should be as least 4mm

2

(12 AWG).

It is advisable to mount one ETL7000 earth terminal at each end of a

column of barriers to provide redundancy by connecting both

ETL7000 terminals to the plant earth. This makes it possible to

introduce a multimeter into one of the loops to measure loop

resistance without breaking the earth connection (figure 16) – a test

which should be done periodically. In these circumstances, resistance

for each cable loop should not exceed 2

Ω.

The IS plant earth conductors should be clearly identified to warn

against unauthorised interference. Though not mandatory, it is

recommended that this should be done by winding blue insulating

tape round the conductors at intervals along their length.

WARNING

Do not use earth foot terminal as an IS earth termination.

Make IS earth connections using an ETL7000 earth

terminal as described in section 5.3.2.

5.3.3

Earthing an earth rail assembly

On installations which include earth rail assemblies (see section

4.3.4) an earth conductor, normally copper wire with a cross-

sectional area of at least 4mm

2

(12AWG) must be connected

between ETM7 earth terminals located at each end of the rail and the

‘spare’ terminals on the ETL7000 terminals at each end of the column

of barriers. See figure 17.

5.3.4

Hazardous-area equipment isolation

Hazardous-area equipment and interconnections should be isolated

from earth sufficiently to be capable of withstanding a 500V isolation

test. Such tests can, however, only be undertaken when the area is

gas free so it is fortunate that most circuits can be tested at low

voltages. To do this:

a) Disconnect from the barrier any cable connected directly to earth

or returned through a barrier with a nominal voltage of less than

10V.

b) Check the resistance to earth of the safe-area terminals with a

multimeter; it should be greater than 100k

Ω.

Note: some hazardous-area equipment (eg, pH and conductivity

instrumentation) is unable to withstand this insulation test. As an

alternative, in these circumstances the system can comply with the

installation requirements described in IS sketch 121. See also

12.2.4.in BS EN 60079-14.

3

4

1

2

MTL7787+

MTL7787P+

Logic signal

1

5

MTL7798

(MTL7799)

3

4

1

2

MTL7706+

MTL7787+

MTL7787P+

250

Ω

3

4

1

2

MTL7741

5

6

7

8

6

0V

0V

1-5V

}

Contact

signals

Power Bus

PB7700

Loop power to

opposite ends to

allow module

removal

Power

Connections

Hazardous

Area

Safe

Area

Figure 14: Typical application of the Power Bus

ETL7000 earth

terminal

To IS earth

Figure 15: Plant earth connection to ETL7000 earth terminal

ETL7000 earth

terminal

Loop

resistance

<2

Ω

Local distribution transformer

Resistance meter or

bond integrity monitor

Figure 16: Earthing an installation with two conductors and

providing resistance test facilities